Blog

Powder characterization for battery electrode manufacturing

Get a better understanding of powder characterization for battery manufacturing with our new blog article.

Introduction

Global warming becomes a major concern in our modern world. Electric cars and renewable energies seem to be workable solutions to solve this problem but storing a large amount of energy in electrical form is essential and remains a big challenge. Therefore, the manufacture of batteries and their improvement is an important topic due to the constant demand for reducing CO2 emissions. Modern batteries require many different qualities such as safety, stability, fast charge, ease of recycling, reasonable costs, etc...[1] These qualities are possible only with a good control of the manufacturing process. A particular attention is paid to the manufacture of the electrodes. Indeed, they play a central role in the good functioning of the battery and its performances.

While the selection of the chemical threesome anode/electrolyte/cathode is important, the structure of the electrodes has a significant influence on the battery performance [2]. The active material constituting the electrode must be the densest as possible to ensure a good ratio weight/capacity. However, at the same time, it should be porous enough to ensure a good charge exchange with the electrolytes, influencing the charge speed of the battery. The quality of the electrodes is therefore a critical point in the manufacturing process.

LEARN MORE ABOUT OUR INSTRUMENTS

Electrodes Manufacturing

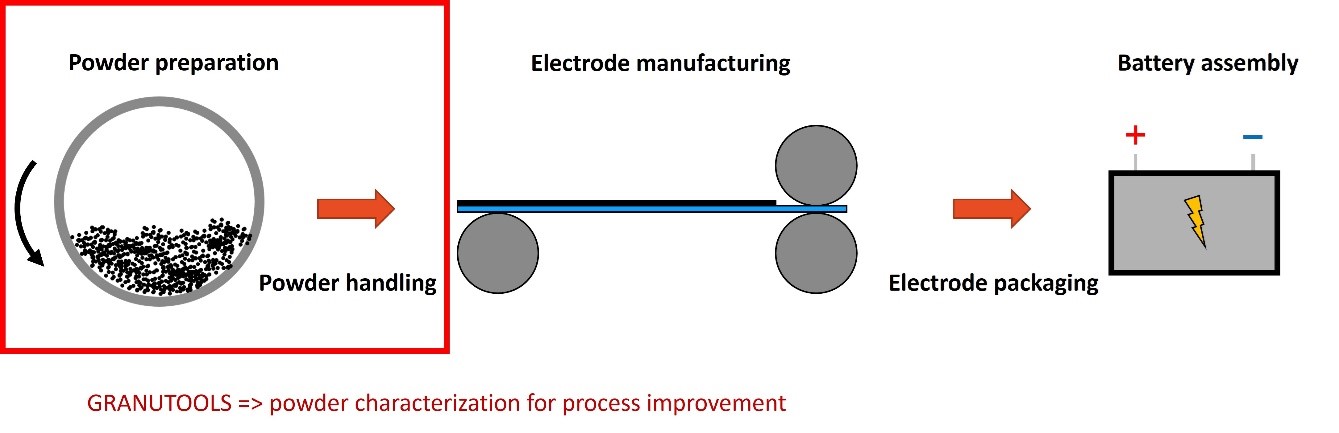

Powders of different natures are used to produce electrodes, especially for All-Solid-State Batteries [3]. Recent works highlighted the influence of the manufacturing process at the powder stage on the battery properties [4]. Powders prepared with different mixing times and different mixing intensities lead to different battery performances. Therefore, the powder preparation is observed to impact the final quality of the battery. In addition, the shaping is a crucial step since the structure of electrodes is important. In the case of All-Solid-State Batteries, the powder must exhibit good flow properties to ensure a good and easy processability and to avoid issues. A good characterization of the powder before its use in process should be established as a good practice for battery cells manufacturing.

Powder characterization

Powders used for batteries manufacturing are mixtures made of active material, that interacts with ions of the electrolyte to exchange electrons during charge or discharge, conductive additive (black carbon most of the time), to improve the conductivity of the electrode, and binder, to improve the adhesion to the current collector and the solidity of the electrode. The three ingredients give raw powders with very different properties and one can therefore expect various bulk behaviours for the blend depending on the kind of mixture and the relative proportions used. However, it is hard to predict the rheology and the flowability of a powder, even based on the knowledge of the grain properties such as the size distribution, the particle shape, and the chemical nature due to the complex interactions between grains and the large number of particles constituting the powder. It is essential to characterize bulk properties of the blend such as the flowability in dry processes since the powder must be conveyed and spread easily on the current collector substrate. The processability can highly depend on the powder and on the shear stress undergone by it. The density of the powder and its ability to increase it can also be important to know since the electrode must be the densest as possible and some processes therefore use calendering to improve this characteristic.

GranuTools provides a set of different instruments that allow to characterize a panel of bulk and rheological properties of powders. These characterizations allow a better understanding on the parameters controlling the powder quality. In addition, the investigation of the powder rheology can help to improve the processability for a better final quality of the electrodes.

LEARN MORE ABOUT OUR INSTRUMENTS

References

[1] S. Li, S.Q. Zhang, L. Shen, Q. Liu, J.B. Ma, W. Lv, Y.B. He and Q.H. Yang, Progress and perspective of ceramic/polymer composite solid electrolytes for lithium batteries, Adv. Sci 7, 1903088 (2020).

[2] W. Bauer, Special features of powder technology for the production of lithium-ion batteries, Interceram-Int. Ceram. Rev. 68, 18-21 (2019).

[3] J. Janek and W. G. Zeier, A solid future for battery development, Nat. Energy 1, 1-4 (2016).

[4] H. Bockholt, W. Haselrieder and A. Kwade, Intensive powder mixing for dry dispersing of carbon black and its relevance for lithium-ion battery cathodes, Powder Technol. 297, 266-274 (2016).

DISCOVER OUR APPLICATION NOTES

Do you have questions about powder characterization ?