Blog

Qualification of GranuTools powder flow instruments: evidencing GranuPack precision and reproducibility

Learn more about our powder flow instruments with this article.

The qualification of powder characterization instruments needs a rigorous methodology with a well selected reference sample. This blog article explains the approach used at GranuTools, illustrated with data. Moreover, from these data, we will evidence the exceptional reproducibility of GranuPack measurements.

Why qualification of powder flow testers is important?

Qualification of powder flow instruments is a very important procedure that requires a rigorous methodology to guarantee reliable measurements during powder testing. An instrument can be considered as qualified when provides repeatable measurements within a fixed range of values. However, to properly qualify the instrument, it is necessary to minimise the measurement variations attributable to the powder used. In fact, if variations due to the powder are higher than or comparable with variations normally caused by the instrument, it is not possible to know whether variations in measurements are attributable to the powder or to the instrument and, consequently, it is not possible to verify whether the instrument is qualified or not. Therefore, it is necessary to find out a reference powder sample for each instrument, that is able to provide repeatable measurements, thus enabling the instrument qualification.

LEARN MORE ABOUT OUR INSTRUMENTS

How to qualify the powder flow instruments?

Suitable powders for qualification of each GranuTools instrument have been chosen based on: 1) the capacity of providing a greater number of repeatable measurements without any “drift” from the values measured at the first test, and 2) the capacity to minimise different sources of measurement variations, thus helping in qualification of the instruments. Possible sources of measurement variations investigated are: re-use of the same sample (σN,max); use of different samples (σS), each of them belonging to a different batch of the same powder; use of different samples from the same batch (σB); use of different instruments (e.g. different GranuPacks) (σI); tests at different relative humidities (σH).

Range of possible values of the measurements for the qualified instrument has been chosen based on the assumption that the normal distribution provides the most conservative prediction of measurement variations, given only the knowledge of the average value and standard deviation (σ). The standard deviation of the distribution has been chosen as the largest value among different standard deviations, each of them related to the afore mentioned sources of measurement variations: σN,max, σS, σB, σI and σH. Therefore, based on the definition of the normal distribution, 99.73 % ≈ 100 % of measurements is assumed to have a value within the average value ± 3 σ.

To quantify all the sources of measurement variations, a coefficient of variation (COV) for each of these sources of variation has been defined. It is related to the corresponding standard deviation. It is defined as: COV= 100*σ/ average value. For example: COV_I=100* σI/average value, where the average value is based on the tests on which the corresponding σ has been evaluated (in the example, σI is calculated based on tests on different instruments). It has been assumed that if the coefficient of variation is lower than 10 % (threshold value), the corresponding measurement variation is acceptable.

For all the powder flow instruments, the sieved powder revealed to be better than the not sieved powder because of lower measurement variations. In the following, details on qualification of the GranuPack are reported.

Qualification of the GranuPack, the high resolution tapped powder density analyzer

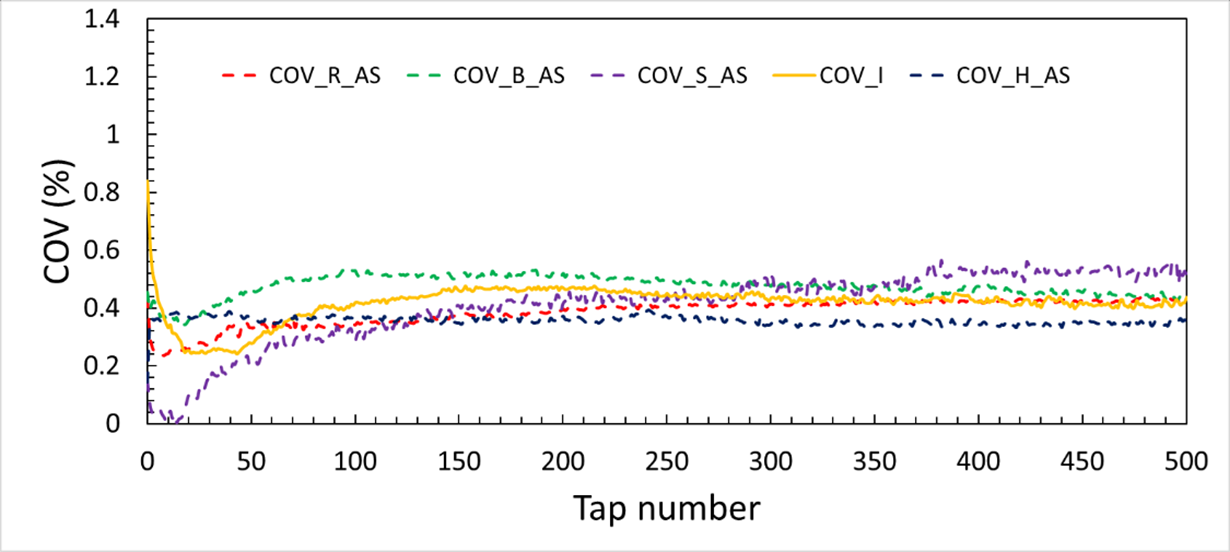

In Figure 1 are reported the measured coefficients of variations, that were found to be lower than 1% (much lower than 10 %), thus proving a good measurement variation for qualification purposes. These coefficients have been evaluated by using the sieved 100-200 µm glass beads powder.

Figure 1: Comparison among different sources of variation in measurements in terms of Coefficient of variation attributable to: reuse of the same sample (COV_R_AS), use of different batches (COV_B_AS), use of different samples from the same batch (COV_S_AS), use of different instruments (COV_I), use of different relative humidities (COV_H_AS). These results have been obtained by using Glass Beads 100-200 µm after sieving (AS).

LEARN MORE ABOUT THE GRANUPACK

Conclusion: Granutools’ powder flow instruments ensure reproducibility

Qualification is an important procedure to which each instrument must be subjected to ensure reliable measurements during powder testing. Glass beads with different particle size distributions have been tested to find the best powder for proper instrument qualification. In case of GranuPack, sieved glass beads with PSD in the range 100-200 µm revealed to be the best choice. In fact, the maximum coefficient of variation lower than 1% demonstrates the good repeatability of the measurements and thus that the sieved 100-200 µm Glass beads powder can be considered as the reference one for the GranuPack qualification. The same procedure has been adopted for other Granutools instruments.

DISCOVER OUR APPLICATION NOTES

Do you have questions about powder characterization ?