Blog

Angle of Repose

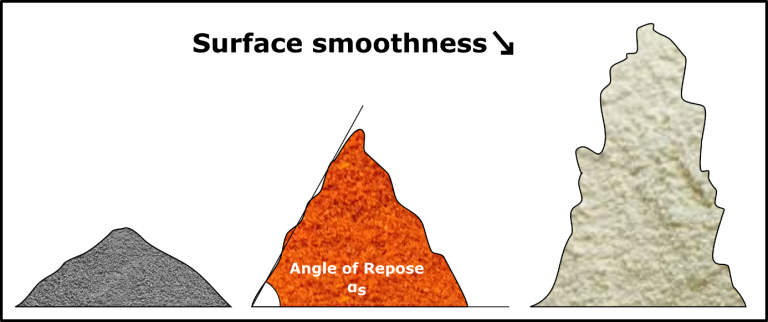

When a powder is poured onto a surface, a heap is formed. It is well known that both the repose angle and the heap shape strongly depend on grain properties (Moisture content, morphology, and particle size distribution, among other parameters, …).

Principle

When a powder is poured onto a surface, a heap is formed. It is well known that both the repose angle and the heap shape strongly depend on grain properties (Moisture content, morphology, and particle size distribution, among other parameters, …). In particular, a cohesive powder forms an irregular heap while a non-cohesive powder forms a regular conical heap.

'The angle of repose or the critical angle of repose, of a granular material

is the steepest angle relative to the horizontal plane which a material

can be piled without slumping or the surface material sliding.'

The angle of repose can range from 0° (theoretical value, unattainable) to 90° (for a solid-like material). Its value is influenced by the interparticle forces (Van der Waals, Capillary, Electrostatic and Contact forces). Therefore, a precise measurement of the heap shape provides useful information about the physical properties of the powder sample and more specifically about powders flowability at low-speed processes.

LEARN MORE ABOUT THE GRANUHEAP

Measurement Standard

User Dependency

Generally, measuring the angle of repose follows on from the Hall Flow test method (ASTM 213) and/or the Carney Flow test (AST M B964) for Additive Manufacturing and the “Flow Through An Orifice” method described in the Pharmacopeia (USP1174). However, it is well-known that those tests have important limitations such as: bad reproducibility, user dependency (for example, a manual or gravity powder feeding may damage the heap, resulting in an abnormal low angle measurement, cf. following video), …

Influence of Angle Calculation

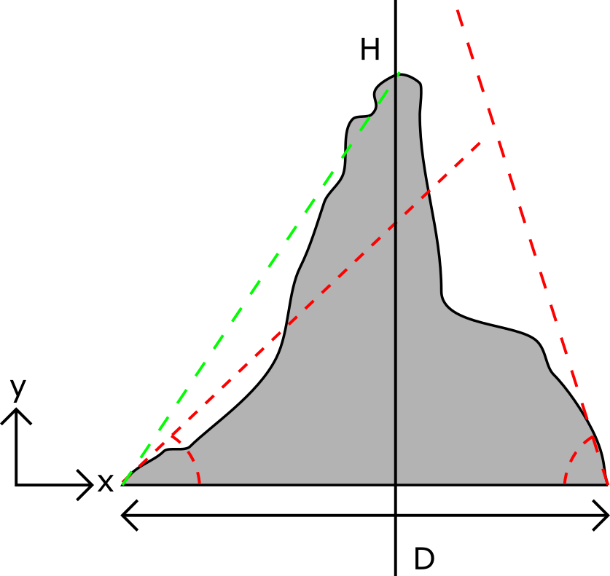

There are several methods for measuring the angle of repose and each produces slightly different results. One of those techniques consists of measuring the powder maximum height (H) and considering the powder is evenly poured onto the centre of the support (heap top theoretically located at x = D/2).

However, despite this way of measurement is acceptable for non-cohesive powders, it is clear that the hypothesis of the heap evenly distributed on the support is not viable for a cohesive material (cf. Figure 2).

GranuTools Solutions

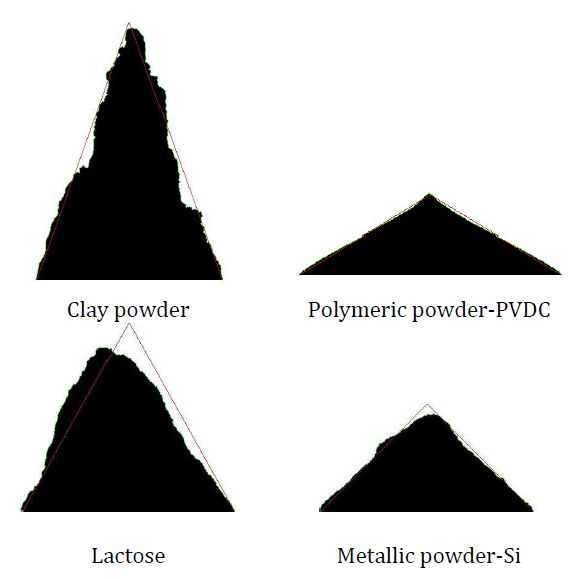

The GranuHeap instrument is an automated heap shape measurement method based on image processing and analysis. A powder heap is created on a cylindrical support. In order to obtain reproducible results, an initialization tube with an internal diameter equal to the circular support is installed on the support. After filling the initialization tube by hand with a fixed volume of powder (typically 100 ml), the tube goes up at the constant speed.

Thereby, the powder is flowing from the tube to form a heap on the cylindrical support. A controlled rotation of the support allows obtaining different heap projections corresponding to different heap orientations. A custom image recognition algorithm determines the position of the powder/air interface. The repose angle refers to the angle of the isosceles triangle with the same surface than the powder heap projected image. This isosceles triangle corresponds to the ideal cohesiveness heap shape.

LEARN MORE ABOUT THE GRANUHEAP

The repose angle is computed for each image, i.e. for each heap orientation. Afterward, an averaged value is computed. In general, the lower the repose angle is, the better the powder flowability is. The deviation between the real heap interface and the isosceles triangular heap provides the static cohesive index. The static cohesive index is computed for each image, i.e. for each heap orientation.

Afterwards, an averaged value is computed. This static cohesive index is close to zero for a non-cohesive powder and increases when the cohesive forces inside the powder strengthen. The next Table summarizes the empirical relation between the results obtained with GranuHeap instrument and powder flowability.

| Flow | Repose Angle (°) | Static Cohesive Index |

| Excellent | 25-30 | < 0.2 |

| Good | 31-35 | 0.3 - 0.5 |

| Fair | 36-40 | 0.6 - 0.8 |

| Passable | 41-45 | 0.9 - 1.2 |

| Poor | 46-55 | 1.3 - 1.7 |

| Very Poor | 56-65 | 1.8 - 2.4 |

| Very very poor | > 66 | > 2.5 |