Food

Characterization of powdered spices to improve processability

In this application note, we present characterization results of different spice and functional mixes used in the food industry. We show how important information on the mix properties can be gathered for these characterizations.

Introduction

Generalities

Many applications in the food industry involve the processing of powders. The formulations of recipes usually require the blending of constituents with different properties in terms of particle sizes and shapes, chemical compositions, or densities. Achieving homogeneous blends is essential to guarantee the consistency of the product between batches during production. However, the mixing of powder is not straightforward. Indeed, contrary to liquids, when a powder is agitated it tends to segregate i.e. separate constituents according to their size. Furthermore, slight changes in formulation properties can lead to major degradations of mixing efficiency that have to be assessed beforehand. Several geometries of mixer are available on the market (see examples in Figure 1), each applying a different stress state to the powder. However, it is well known that powder behavior can strongly depend on the stress state at which it is processed. Therefore, blend characterization in R&D must take into account the dynamical aspect of the blending process.

Figure 1: Single shaft ribbon and high-shear mixer. Courtesy of M. Ong, Saue Production OÜ.

The conditioning of the final product is also a crucial part of the production of food products. Control of the filling process is essential to ensure a proper filling of the bags to meet the targeted mass of product. With cohesive powders demonstrating low flowability problems can arise during the conveying through the mixing and conveying machines. On the opposite, too flowable powders or the presence of very fine particles in the blends can lead to overfill problems due to the valves not holding correctly the mix. This induces deviation from the targeted mass of the bag and subsequent problems during the sealing. Moreover, powder leakage contributes to a deficit of order and degradation of the work environment.

To improve these industrial processes, a better understanding of the powder behavior is necessary. More specifically, a relevant powder characterization during product development allows predicting the behavior of the blends in the production line. Indeed, knowledge of the characteristics of the constituents taken independently is not sufficient to predict the final blend behavior. However, most of the techniques used in R&D or quality control laboratories are based on old measurement techniques. During the last decade, GranuTools updated these techniques to meet the present requirements of R&D laboratories and production departments. In particular, the measurement processes have been automatized and rigorous initialization methods have been developed to obtain reproducible and interpretable results. Moreover, the use of image analysis techniques improves measurement precision. Many industries are already using GranuTools instruments range in different fields: additive manufacturing, food processing, pharmaceuticals, bulk material handling.

Figure 2: Bag overfill due to valve that doesn’t hold the mix. Courtesy of M. Ong, Saue Production OÜ

In this application note, we present characterization results of different spice and functional mixes used in the food industry. We show how important information on the mix properties can be gathered for these characterizations. The new insights provided by these high-end methods will help to design better products to improve production lines.

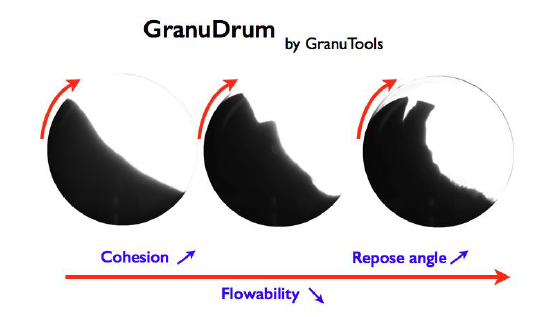

Granudrum

The GranuDrum instrument is an automated powder flowability measurement method based on the rotating drum principle. A horizontal cylinder with transparent sidewalls called drum is half filled with the sample of powder. The drum rotates around its axis at an angular velocity ranging from 2 rpm to 60 rpm. A CCD camera takes snapshots (30 to 100 images separated by 1s) for each angular velocity. The air/powder interface is detected on each snapshot with an edge detection algorithm. Afterward, the average interface position and the fluctuations around this average position are computed. Then, for each rotating speed, the flowing angle (also known in the literature as ‘dynamic angle of repose’) αf is computed from the average interface position and the dynamic cohesive index σf is measured from the interface fluctuations.

LEARN MORE ABOUT THE GRANUDRUM

In general, a low value of the flowing angle αf corresponds to a good flowability. The flowing angle is influenced by a wide set of parameters: the friction between the grains, the shape of the grains, the cohesive forces (van der Waals, electrostatic and capillary forces) between the grains. The dynamic cohesive index σf is only related to the cohesive forces between the grains. A cohesive powder leads to an intermitted flow while a non-cohesive powder leads to a regular flow. Therefore, a dynamic cohesive index closes to zero corresponds to a non-cohesive powder. When the powder cohesiveness increases, the cohesive index increases accordingly. In addition to the measurement of both the cohesive index σf and the flowing angle αf as a function of the rotating speed, the GranuDrum allows to measure the first avalanche angle and the powder aeration during the flow.

Figure 3: Sketch of GranuDrum measurement principle

GranuPack

The GranuPack instrument is an automated and improved tapped density measurement method based on recent fundamental research results. The behaviour of the powder submitted to successive taps is analyzed with an automatized device. The Hausner ratio Hr, the initial density ρ(0) and the final density after n taps ρ(n) are measured precisely. The tap number is commonly fixed at n=500. Moreover, a dynamical parameter, the slope index α defined as the slope of the packing curve at the initial stage of packing, can be extracted to characterize the packing dynamics.

LEARN MORE ABOUT THE GRANUPACK

The powder is placed in a metallic tube with a rigorous automated initialization process. Afterward, a light hollow cylinder is placed on the top of the powder bed to keep the powder/air interface flat during the compaction process. The tube containing the powder sample rose up to a fixed height of ΔZ and performs free falls. The free fall height is generally fixed to ΔZ = 1mm or ΔZ=3mm. The height h of the powder bed is measured automatically after each tap. From the height h, the volume V of the pile is computed. As the powder mass m is known, the density ρ is evaluated and plotted after each tap. The density is the ratio between the mass m and the powder bed volume V. With the GranuPack method, the results are reproducible with a small quantity of powder (typically 35 ml). The Hausner ratio Hr is related to the compaction ratio and is calculated by the equation Hr = ρ(n) / ρ(0) , where ρ(0) is the initial bulk density and ρ(n) the tapped density computed obtained after n taps.

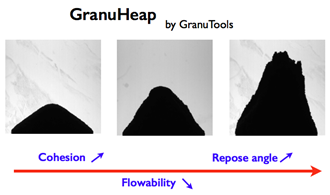

GranuHeap

When a powder is poured onto a surface, a heap is formed. It is well known that both the repose angle and the heap shape strongly depend on grain properties. In particular, a cohesive powder forms an irregular heap while a non-cohesive powder forms a regular conical heap. Therefore, a precise measurement of the heap shape provides useful information about the physical properties of the powder sample.

LEARN MORE ABOUT THE GRANUHEAP

Figure 4: Sketch of GranuHeap measurement principle

The GranuHeap instrument is an automated heap shape measurement method based on image processing and analysis. A powder heap is created on a cylindrical support. In order to obtain reproducible results, an initialization tube with an internal diameter equal to the circular support is installed on the support. After filling the initialization tube by hand with a fixed volume of powder (typically 100 ml), the tube goes up at a constant speed. Thereby, the powder is flowing from the tube to form a heap on the cylindrical support. A controlled rotation of the support allows obtaining different heap projections corresponding to different heap orientations. A custom image recognition algorithm determines the position of the powder/air interface. The repose angle refers to the angle of the isosceles triangle with the same surface as the powder heap projected image. This isosceles triangle corresponds to the ideal cohesiveness heap shape. The repose angle is computed for each image, i.e. for each heap orientation. Afterward, an averaged value is computed. In general, the lower the repose angle is, the better the powder flowability is.

LEARN MORE ABOUT THE GRANUHEAP

The deviation between the real heap interface and the isosceles triangular heap provides the static cohesive index. The static cohesive index is computed for each image, i.e. for each heap orientation. Afterward, an averaged value is computed. This static cohesive index is close to zero for a non-cohesive powder and increases when the cohesive forces inside the powder strengthen. In this application note, we will focus on the repose angle to get a simple powder flowability characterization.

Powders Description

Five powders used as a marinade in the food industries have been investigated. Powders have been provided by the Saue Production OÜ company, a member of Solina Group Northern-Europe Division, a leader in the spice mixes supplying.

These selected powders differ in terms of particle size and shape as well as chemical composition in order to demonstrate the wide range of applicability of the characterization methods presented in this application note.

GranuHeap Analysis

Quality control in production requires fast and reliable characterization of batches to detect drifts in powder properties and take action to prevent degradation of the process efficiency. However, the old tests commonly used are becoming obsolete due to the increasing needs of modern productions. In this section, we will see how the GranuHeap measurement can provide fast and easily interpretable results to get a classification of powder properties.

Experimental Protocol

For each experiment with the GranuHeap instrument, the 40mm diameter support was selected. 16 pictures were taken during the heap rotation (1 picture each 11.25°) to increase the measurement accuracy. At the end of the analysis, one final picture is taken to check the pile integrity when the measurement is done. Every powder was analyzed under ambient conditions (46.6 ± 0.8 %RH and 25.0 ± 0.2 °C). Measurements have been repeated three times to assess reproducibility.

LEARN MORE ABOUT THE GRANUHEAP

Experimental Results

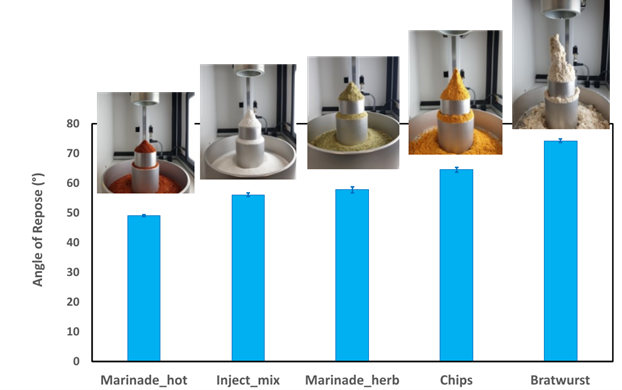

Figure 5 presents the angle of repose measured for every powder. The angle of repose of a powder depends mainly on the particle size and shape, but also on the cohesive interactions lying between them. The angle of repose can thus be used as a measure of the powder flowability, a higher angle of repose indicates a lower flowability. The tested powders can be easily classified, with angles of repose ranging from 50° to 70°. The Marinade_hot shows the lowest angle of repose, and thus is expected to demonstrate the highest flowability among the different powders. On the opposite, the Bratwurst exhibits an angle of repose above 70°, denoting a strongly cohesive behavior.

Pictures of the heap shape taken for each powder are also displayed. A more flowable powder will usually form a smoother and more symmetric heap, as can be observed for the marinade hot. Upon increasing the cohesiveness, a more irregular and non-symmetric heap can be sustained due to higher cohesive interactions between the grains composing the powder. This is clearly evidenced for the Bratwurst.

The GranuHeap angle of repose measure thus provides a fast and simple way to classify the flowability of the powders. The high accuracy of the instrument provided by the user independent image analysis allows reproducible measurements which is a requirement for high-end product development. However, the powder is here investigated in a static regime that can be far from what it experiences in a real process. Indeed, it is well known that the behavior of a powder strongly depends on the stress state at which it is processed. To get more insight on the rheological behavior, a set of complementary tools, especially the use of dynamic method, is necessary.

LEARN MORE ABOUT THE GRANUHEAP

Figure 5: Angle of repose measured with the GranuHeap. Powders can be easily classified according to their angle of repose. Pictures of the obtained heap are also displayed

GranuPack Analysis

The packing properties of the powder, i.e. its ability to form a dense assembly, is another interesting way to evaluate powder properties. Indeed, the packing ability of a powder strongly depends on its particle properties as well as cohesive interactions lying between the particles. Numerous industrial applications involve the packing of powders. For example, the packing ability of the processed powder has to be taken into account for bag filling to prevent overweighting or overfilling of the bags. In this section, we will investigate the packing properties of the different marinade powders.

LEARN MORE ABOUT THE GRANUPACK

Experimental Protocol

For a measurement with the GranuPack, only 35ml of powders is required. Taps of 1mm height have been used and a sequence of 500 taps at a frequency of 1 tap/s is applied. In order to remove the operator dependency during the pouring of the powder in the measurement cell, the following initialization protocol has been developed:

- An initialization tube (hollow cylinder) is placed inside the cell

- The powder is poured inside the initialization tube by the operator

- The initialization tube automatically moves upward at a constant speed

This initialization protocol ensures that the powder is always poured the same way by removing operator dependency. To flatten the surface, a light diabolo is gently placed on top of the powder bed. Once the initialization procedure is performed, the inductive sensor comes in the vicinity of the diabolo and the tap sequence starts. After each tap, the powder height is automatically measured by the sensor without the intervention of the operator.

Measurements were repeated three times for evaluating reproducibility and the average value and standard deviation were considered. Before the experiment, air relative humidity (RH, 40.1 ± 1.7 %) and temperature (23.4 ± 0.8 °C) are recorded.

Experimental Results

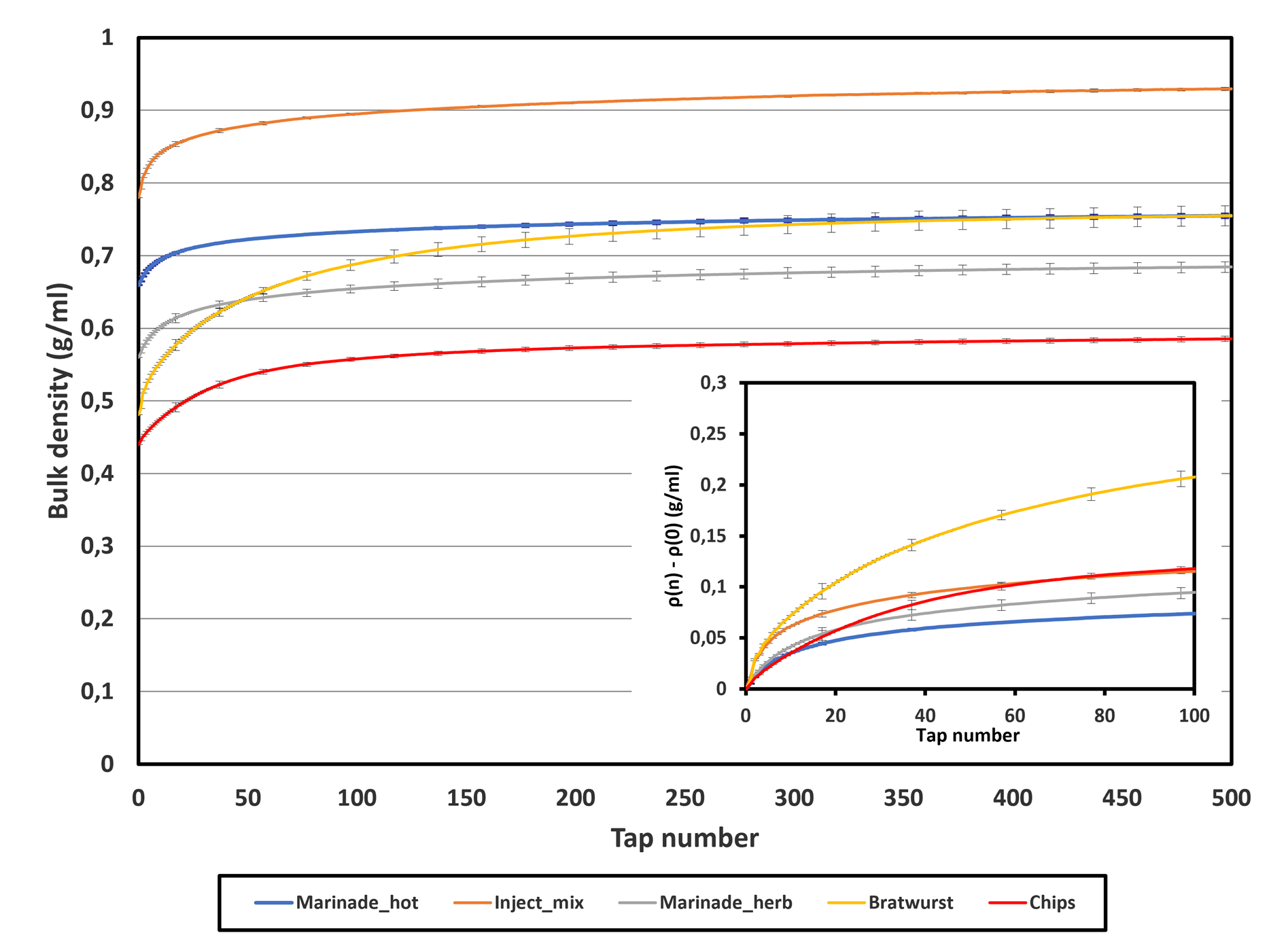

The initial bulk density (ρ(0)), the final bulk density (at a number of taps, n = 500 ; i.e. ρ(500)), the Hausner ratio (Hr = ρ(0)/ ρ(500)), and the parameter linked to the compaction dynamics (n1/2) are summarized on Table 1 and the complete packing curves are presented on Figure 6.

| Sample Name | ρ(0) (g/ml) | ρ(n) (g/ml) | Hr | Slope index (g/l) |

| Marinade_hot | 0,659 | 0,755 | 1,15 | 3,6 |

| Inject_mix | 0,780 | 0,930 | 1,19 | 6,2 |

| Marinade_herb | 0,560 | 0,684 | 1,22 | 4,3 |

| Chips | 0,440 | 0,585 | 1,33 | 3,5 |

| Bratwurst | 0,481 | 0,755 | 1,57 | 7,4 |

Table 1: Summary of the GranuPack results obtained for the evaluated powders

The Hausner ratio gives a classification of the powders cohesiveness. Indeed, a more cohesive powder is able to sustain a loose packing at rest due to the cohesive interactions opposing the weight of the particles. The packing amplitude is thus more important for cohesive powders, and the ratio of the tapped density to the initial density gives an indication of the strength of these cohesive interactions. Moreover, the flowability of the powder is directly related to its cohesiveness, the Hausner ratio is thus used as an indirect measure of the powder flowability.

LEARN MORE ABOUT THE GRANUPACK

The Marinade hot exhibits a Hausner ratio of 1.15, denoting a good flowability. On the opposite, the high Hausner ratio of the Bratwurst indicated a strong cohesive behavior and thus a low flowability. The flowability classification obtained with the Hausner ratio is the same as the repose angle presented above. Indeed, despite the differences in the measurement method, the repose angle and the Hausner ratio depend on the same powder micro properties. However, the tapped density analysis provides deeper insights into powder behavior.

Figure 6: Bulk density versus the number of applied taps for the different powders. Insert: data reduced by initial density (ρ(n)- ρ(0)) to highlight the kinetics of the initial packing stage

The GranuPack instrument allows to access the full packing curves, providing useful information that is not accessible with standard tap-tap tests (see AN: Tapped density characterization: comparison between the GranuPack and a standardized method). The packing curves obtained for the five marinade powders are presented in Figure 6. The bulk density increases faster at the initial stage of the packing (< 100 taps) then slows down to reach a plateau. Indeed, after each tap the grains rearrange to fill the voids and increase the powder density, leading to a progressive reduction of their mobility. When the maximal density is reached the grains are no longer able to move freely, subsequent taps do not allow to increase the powder density.

The packing curves give useful information on the packing dynamics of the powders. The slope index α is extracted from these curves and reported in Table 1. A high slope index indicates a fast packing behavior. The insert in Figure 6 presents the packing curves for the 100 first taps, reduced by the initial density (ρ(n)- ρ(0)) to highlight the differences in packing dynamics. We can clearly identify two different behavior: the Bratwurst and Inject_mix have a faster initial packing than the Marinade_herb, Marinade_Hot and Chips. Therefore, it appears that the dynamics of packing is not directly related to the flowability, i.e. a powder with a good flowability will not necessarily exhibit a faster packing. This gives very interesting information on the powder properties, especially in processes that involve, deliberately or not, the packing of powders. For example, during the bag filling process, a powder denoting a fast packing dynamics should produce more dense packing. This can be beneficial to prevent bag overfill and sealing issues, however it may promote caking problems during storage. The packing dynamics is thus an important parameter that has to be characterized to get a complete understanding of the expected powder behavior in a specific process.

Investigation of caking with the GranuDrum

Caking of powders is a major problem in the food powder production industry. Indeed, during storage in silo or bags, solid bridges can develop between the particles due to chemical reactions or solidification of the liquid bridges. This leads to the formation of agglomerates and subsequent modification of the powder flowing properties (fig. Figure 7). Moreover, in extreme cases, the powder can completely solidify and then requires mechanical breakage to regain flowability.

LEARN MORE ABOUT THE GRANUDRUM

Therefore, the characteristics of the powder at the customer facility are far from the specifications evaluated by the producer before storage. The evaluation of the caking propensity of a new powder/formulation is essential to anticipate such problems and improve product quality. In this section, we will show how the GranuDrum instrument can be used to investigate the caking sensibility of the marinade hot powder.

Figure 7: Agglomerates appearing in bags due to caking

Experimental Protocol

Caking Procedure

The marinade hot powder has been selected for this study. A volume of 50ml has been placed in a special caking tool that allows applying vertical pressure on the powder with a 200g mass. Applying pressure to the sample promotes caking by increasing the bulk density and thus reducing the distance between the particles. This procedure is used to mimic the pressure applied to the powder when stored in silo or bags.

GranuDrum Measurement

For an experiment with the GranuDrum, 50ml of powder is poured inside the measurement cell. The cell rotates at several velocities (from 2 to 60 rpm) to evaluate the rheological behavior of the powder and for each velocity, 40 pictures separated by 1s are taken. The powder/air interface position is accurately computed numerically. The cohesive index, a measure of the cohesiveness of the powder, is then computed from the temporal fluctuations of this powder/air interface position. Caked and uncaked samples have been evaluated separately with the GranuDrum.

LEARN MORE ABOUT THE GRANUDRUM

Experimental Results

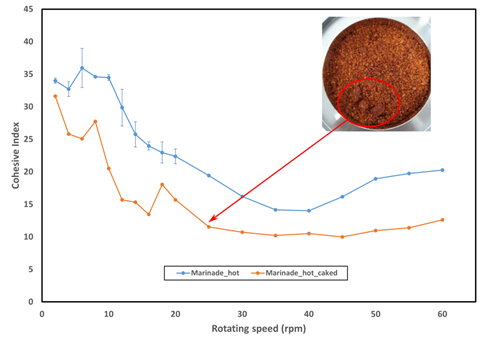

Figure 8: Cohesive index versus drum rotating speed for caked (orange) and uncaked (blue) marinade hot samples

Figure 8 presents the cohesive index obtained for different rotating speeds for the fresh (uncaked) and the caked powder. Both samples exhibit a shear-thinning behavior, i.e. a decrease of cohesiveness with increasing rotating speeds. This rheological behavior indicates that the powders should see their flowability increase when submitted to higher process stress, which can be interesting for process optimization.

After being submitted to the caking protocol, the powder shows a lower cohesive index than the fresh powder for the whole range of speeds. At first, this may be counter-intuitive as caking is expected to degrade the powder flowability. However, this decrease in cohesiveness can be explained by the formation of agglomerates due to caking leading to larger average particle size. Indeed, the solid bridges that form between the particles during caking tend to produce mechanically stable agglomerates. Moreover, the larger the particle size the lower the influence of the cohesive interactions on the global collective behavior of the powder. The decrease of cohesiveness at the initial stage of caking is thus an indicator of the caking ability of a powder. Therefore, the cohesive index measure provides an interesting way to evaluate the first stage of caking of powders.

Conclusions

Five powders used in the food industry as marinades have been evaluated with the GranuHeap, GranuPack and GranuDrum instruments. We have shown that each characterization method provides useful information on the powder behavior. The flowability of the powders has been easily classified according to their angle of repose with the GranuHeap. Then, deeper insights on the powder properties were obtained with the GranuPack tapped density analysis. Finally, the GranuDrum instrument has been used to evaluate the caking propensity of the marinade hot powder.

This study demonstrated the advantages of using modern characterization techniques to get a better understanding of the powder behavior. This knowledge can then be directly applied to solve industrial problems and improve production lines and product quality. Furthermore, the high accuracy of the GranuTools instruments allows highlighting small changes in the mix formulation that can impact the product performance.

Acknowledgments

We thank Madli Ong from Saue Production OÜ for providing the powder for this study, as well as useful insights on production challenges.

Bibliography

Cascade of granular flows for characterizing segregation, G. Lumay, F. Boschin, R. Cloots, N. Vandewalle, Powder Technology 234, 32-36 (2013).

Combined effect of moisture and electrostatic charges on powder flow, A. Rescaglio, J. Schockmel, N. Vandewalle and G. Lumay, EPJ Web of Conferences 140, 13009 (2017).

Compaction dynamics of a magnetized powder, G. Lumay, S. Dorbolo and N. Vandewalle, Physical Review E 80, 041302 (2009).

Compaction of anisotropic granular materials: Experiments and simulations, G. Lumay and N. Vandewalle, Physical Review E 70, 051314 (2004).

Compaction Dynamics of Wet Granular Assemblies, J. E. Fiscina, G. Lumay, F. Ludewig and N. Vandewalle, Physical Review Letters 105, 048001 (2010).

Effect of an electric field on an intermittent granular flow, E. Mersch, G. Lumay, F. Boschini, and N. Vandewalle, Physical Review E 81, 041309 (2010).

Effect of relative air humidity on the flowability of lactose powders, G. Lumay, K. Traina, F. Boschini, V. Delaval, A. Rescaglio, R. Cloots and N. Vandewalle, Journal of Drug Delivery Science and Technology 35, 207-212 (2016).

Experimental Study of Granular Compaction Dynamics at Different Scales: Grain Mobility, Hexagonal Domains, and Packing Fraction, G. Lumay and N. Vandewalle, Physical Review Letters 95, 028002 (2005).

Flow abilities of powders and granular materials evidenced from dynamical tap density measurement, K. Traina, R. Cloots, S. Bontempi, G. Lumay, N. Vandewalle and F. Boschini, Powder Technology, 235, 842-852 (2013).

Flow of magnetized grains in a rotating drum, G. Lumay and N. Vandewalle, Physical Review E 82, 040301(R) (2010).

How tribo-electric charges modify powder flowability, A. Rescaglio, J. Schockmel, F. Francqui, N. Vandewalle, and G. Lumay, Annual Transactions of The Nordic Rheology Society 25, 17-21 (2016).

Influence of cohesives forces on the macroscopic properties of granular assemblies, G. Lumay, J. Fiscina, F. Ludewig and N. Vandewalle, AIP Conference Proceedings 1542, 995 (2013).

Linking compaction dynamics to the flow properties of powders, G. Lumay, N. Vandewalle, C. Bodson, L. Delattre and O. Gerasimov, Applied Physics Letters 89, 093505 (2006).

Linking flowability and granulometry of lactose powders, F. Boschini, V. Delaval, K. Traina, N. Vandewalle, and G. Lumay, International Journal of Pharmaceutics 494, 312–320 (2015).

Measuring the flowing properties of powders and grains, G. Lumay, F. Boschini, K. Traina, S. Bontempi, J.-C. Remy, R. Cloots, and N. Vandewalle, Powder Technology 224, 19-27 (2012).

Motion of carbon nanotubes in a rotating drum: The dynamic angle of repose and a bed behavior diagram, S. L. Pirard, G. Lumay, N. Vandewalle, J-P. Pirard, Chemical Engineering Journal 146, 143-147 (2009).

Mullite coatings on ceramic substrates: Stabilisation of Al2O3–SiO2 suspensions for spray drying of composite granules suitable for reactive plasma spraying, A. Schrijnemakers, S. André, G. Lumay, N. Vandewalle, F. Boschini, R. Cloots and B. Vertruyen, Journal of the European Ceramic Society 29, 2169–2175 (2009).

Rheological behavior of β-Ti and NiTi powders produced by atomization for SLM production of open porous orthopedic implants, G. Yablokova, M. Speirs, J. Van Humbeeck, J.-P. Kruth, J. Schrooten, R. Cloots, F. Boschini, G. Lumay, J. Luyten, Powder Technology 283, 199–209 (2015).

The flow rate of granular materials through an orifice, C. Mankoc, A. Janda, R. Arévalo, J. M. Pastor, I. Zuriguel, A. Garcimartín and D. Maza, Granular Matter 9, p407–414 (2007).

The influence of grain shape, friction and cohesion on granular compaction dynamics, N. Vandewalle, G. Lumay, O. Gerasimov and F. Ludewig, The European Physical Journal E (2007).