Application notes

Measuring powder air permeability with GranuPack

The GranuPack instrument can be equipped with a measurement cell allowing a permeability measurement. This measurement characterizing the ability of air to pass through a powder is of crucial importance for many applications.

Introduction

The ability of the air to pass through a powder is of crucial importance for many applications. For example, at the aperture of a silo, the air must enter inside the silo when the powder comes out. Therefore, a powder having a high air permeability will flow well from a silo. In tabletting applications, the air flow through the powder during the die filling process also plays an important role. In dry powder inhalers, the ability of the air to fluidize and aerosolize the powder is also directly linked to powder permeability.

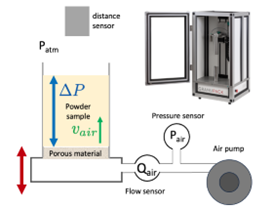

The GranuPack instrument can be equipped with a measurement cell allowing a permeability measurement (see Figure 1).

Figure 1: sketch of the permeability measurement kit for GranuPack.

LEARN MORE ABOUT THE GRANUPACK

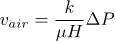

An air flow passes vertically through a powder in a vertical cylinder of height H and section S (expressed respectively in m and m2). If the powder is considered as a porous media, the link between the air velocity in the powder vair (expressed in m/s) and the pressure drop ΔP (expressed in Pa) is given by the Darcy law:

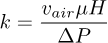

where k is the Darcy permeability (expressed in m2) and µ is the air viscosity (expressed in Pa.s). The pressure drop ΔP is the difference between the pressure of the air inserted at the bottom of the cell Pair and the atmospheric pressure Patm, which is the pressure at the top powder/air interface. By measuring the air flow velocity vair and the pressure drop ΔP, the permeability k can be evaluated:

The air viscosity at standard atmospheric conditions is m = 18.5 10-6 Pa.

This air flow is characterised by the air flow rate Qair (commonly expressed in L/min). The link between the air flow rate Qair and the air velocity in the powder vair is

The GranuPack associated with the permeability cell is a highly versatile instrument allowing the measurement of many physical parameters due to the association of the classical GranuPack packing measurement with the permeability. Indeed, as shown by Figure 2, the interplay between the tapping mechanism inducing an increase of the packing fraction and the air flow inducing a powder fluidization leads to a high variety of behaviours.

Figure 2: Interplay between packing dynamics and fluidization leading to a variety of behaviours.

LEARN MORE ABOUT THE GRANUPACK

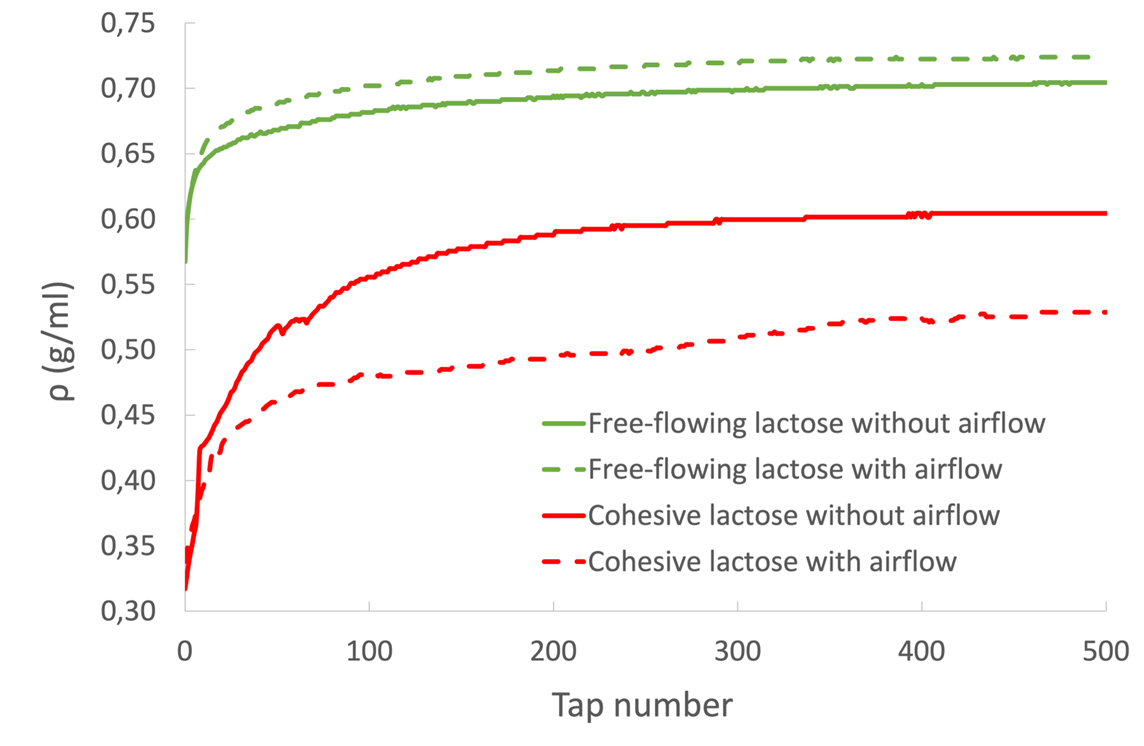

Figure 3 illustrates the richness of packing behaviours when combining packing and fluidization. Without air flow, the free-flowing powder has a higher packing fraction and a faster packing dynamics than the cohesive powder. This is a very classical result with the GranuPack. The application of an air flow during the packing experiment is found to modify the packing dynamics. Moreover, the effect on free-flowing or cohesive powders is different. The air flow improves the packing dynamics of free-flowing powders while it reduces the packing dynamics of cohesive powders.

Figure 3: Packing curves obtained with two common lactose powders: a free-flowing one and a cohesive one. For both powders, the packing measurement was performed with and without airflow.

Given these results, the measurement protocol selection is important. For this application note, we selected the simplest one with a permeability measurement before and after the packing curve measurement, without any air flow in between. More precisely, the following steps were considered:

- The powder is poured inside the measurement cell using the classical GranuPack initialisation protocol to remove any user dependency on the initial density. At this stage, the air flow rate is zero;

- The air flow rate is set to a selected value and a permeability measurement is performed to obtain the initial permeability k(0). Afterwards, the air flow rate is set to zero;

- 500 taps are applied to the sample and a packing curve is measured;

- The air flow rate is set to a selected value and a permeability measurement is performed to obtain the final permeability k(500).

Therefore, we obtain finally the initial permeability k(0) corresponding to the initial bulk density ρ(0) and the final permeability k(500) corresponding to the final tapped density ρ(500). Finally, the permeability ratio Δk=k(0)/k(500) characterizes the permeability decrease during a tapping experiment. The definition of this parameter is comparable to the definition of the Hausner ratio characterizing the density increase during a tapping experiment. However, it is important to point out that Hr=ρ(500)/ ρ(0) because ρ(500)>ρ(0), while Δk=k(0)/k(500) because k(0)> k(500) and both Hr and Δk are higher than unity.

LEARN MORE ABOUT THE GRANUPACK

Powders Description

Three Pharmatose® lactose powders from DFE Pharma having different size distribution have been analysed with GranuPack equipped with the permeability measurement cell. Table 1 shows the granulometric information about the powder.

| Powder | d10 [µm] | d50 [µm] | d90 [µm] |

|---|---|---|---|

| Pharmatose® 150M (P150M) | 6 | 60 | 210 |

| Pharmatose® 200M (P200M) | 5 | 40 | 120 |

| Pharmatose® 450M (450M) | 3 | 20 | 50 |

Table 1: Powder names and short names with the main indexes characterizing the grain size distributions.

Pharmatose® are pure white and highly consistent crystalline, milled lactose monohydrate grades mechanically milled to varying degrees of particle. Due to its fine nature and relatively high surface area, milled lactose compacts well. This lactose type is typically used in tablets, capsules and extrusion spheronisation.

The powder P450M is cohesive while P150M is free flowing and P200M is intermediate.

Results

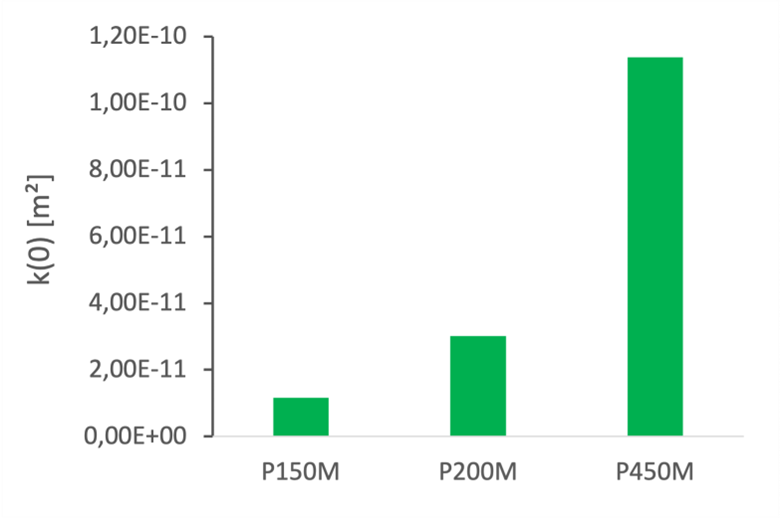

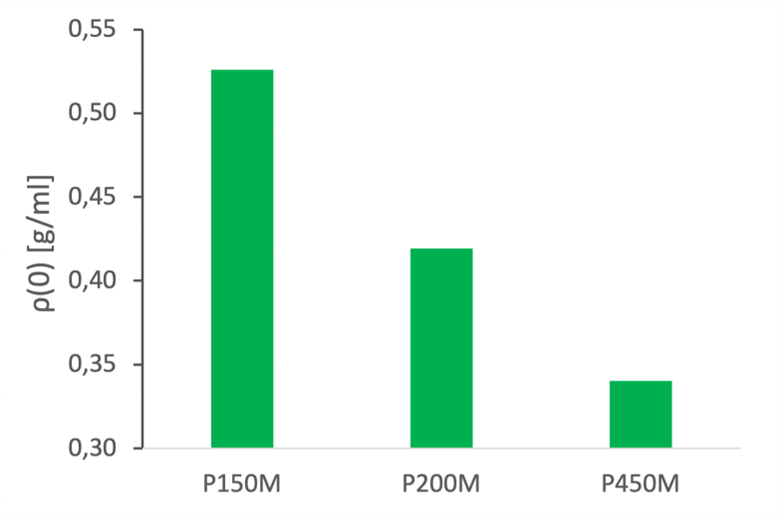

Figure 4 shows the initial density ρ(0) and the corresponding permeability k(0) for each lactose powder. The free-flowing powder P150M has a low initial permeability because its initial density is relatively high. At the opposite, the cohesive powder P450M shows a higher initial permeability because its initial density is much lower. Indeed, the cohesive forces is stabilizing a loose packing having a high porosity. Therefore, at the initial bulk conditions, the permeability increases with the cohesiveness.

.png)

.png)

Figure 4: Initial permeability k(0) and density ρ(0).

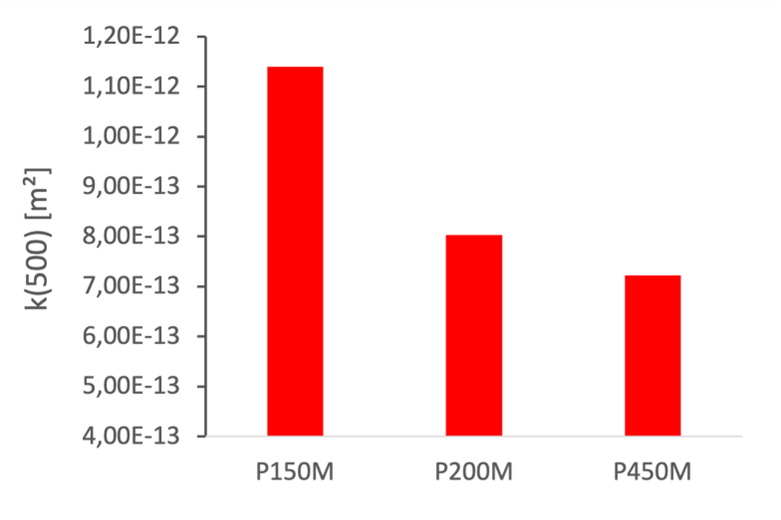

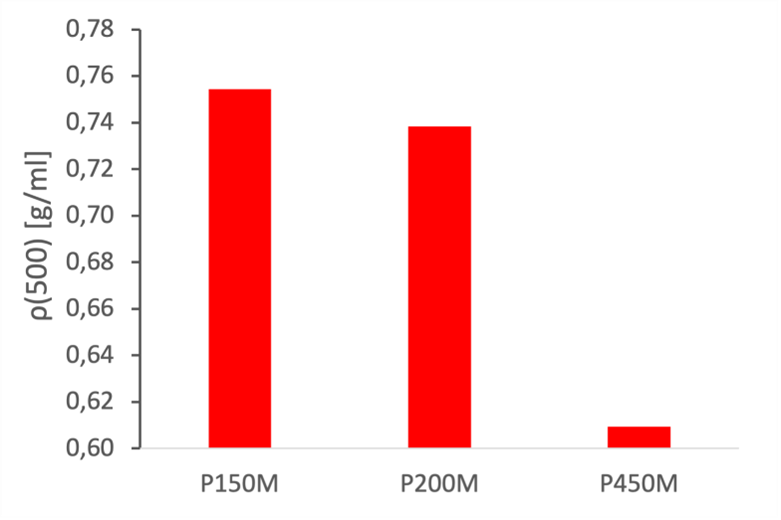

Figure 5 shows the final density ρ(500) and the corresponding permeability k(500) for each lactose powder after 500 taps. Compared to the initial situation, the trend is inverted for the permeability. The free-flowing powder P150M has a higher final permeability than the cohesive powder P450M. This is explained by the higher densification of the cohesive powder as show hereafter with the Hausner ratio. Therefore, after the powder densification by tapping, the permeability decreases with the cohesiveness.

measured after 500 taps.png)

measured after 500 taps.png)

Figure 5: Final permeability k(500) and density ρ(500), both measured after 500 taps.

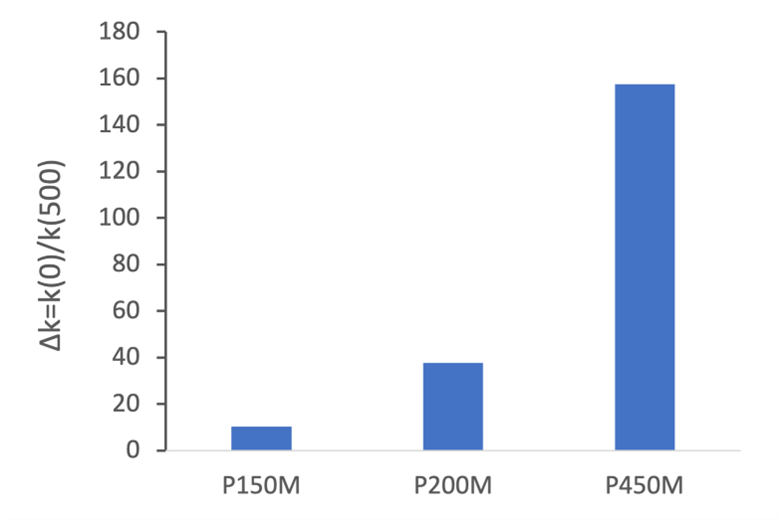

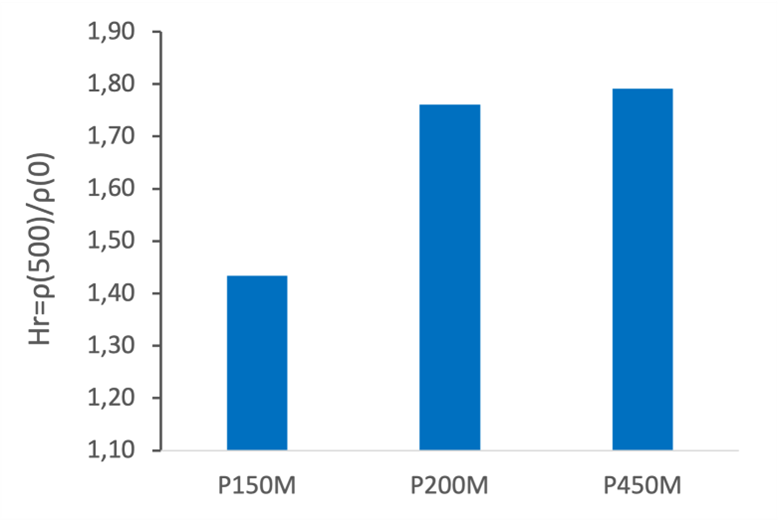

Figure 6 shows the permeability variation Δk during the tapping experiment. The free-flowing powder P150M experiences only a reduce variation of the permeability while the cohesive powder P450M experience a drastic permeability variation. For this cohesive powder, the final permeability is more than 150 times higher than the initial one. Of course, the Hausner ratio is also higher for this cohesive powder but the effect on the permeability is obviously non-linear.

Figure 6: Permeability variation Δk and Hausner ratio Hr

Conclusions

The information coming from a packing experiment combined with permeability measurements are showing that the results are complementary and non-redundant. The permeability is found to be highly sensitive to the packing fraction, showing the importance to combine packing and permeability measurement.

LEARN MORE ABOUT THE GRANUPACK

Bibliography

Cascade of granular flows for characterizing segregation, G. Lumay, F. Boschin, R. Cloots, N. Vandewalle, Powder Technology 234, 32-36 (2013).

Combined effect of moisture and electrostatic charges on powder flow, A. Rescaglio, J. Schockmel, N. Vandewalle and G. Lumay, EPJ Web of Conferences 140, 13009 (2017).

Compaction dynamics of a magnetized powder, G. Lumay, S. Dorbolo and N. Vandewalle, Physical Review E 80, 041302 (2009).

Compaction of anisotropic granular materials: Experiments and simulations, G. Lumay and N. Vandewalle, Physical Review E 70, 051314 (2004).

Compaction Dynamics of Wet Granular Assemblies, J. E. Fiscina, G. Lumay, F. Ludewig and N. Vandewalle, Physical Review Letters 105, 048001 (2010).

Effect of an electric field on an intermittent granular flow, E. Mersch, G. Lumay, F. Boschini, and N. Vandewalle, Physical Review E 81, 041309 (2010).

Effect of relative air humidity on the flowability of lactose powders, G. Lumay, K. Traina, F. Boschini, V. Delaval, A. Rescaglio, R. Cloots and N. Vandewalle, Journal of Drug Delivery Science and Technology 35, 207-212 (2016).

Experimental Study of Granular Compaction Dynamics at Different Scales: Grain Mobility, Hexagonal Domains, and Packing Fraction, G. Lumay and N. Vandewalle, Physical Review Letters 95, 028002 (2005).

Flow abilities of powders and granular materials evidenced from dynamical tap density measurement, K. Traina, R. Cloots, S. Bontempi, G. Lumay, N. Vandewalle and F. Boschini, Powder Technology, 235, 842-852 (2013).

Flow of magnetized grains in a rotating drum, G. Lumay and N. Vandewalle, Physical Review E 82, 040301(R) (2010).

How tribo-electric charges modify powder flowability, A. Rescaglio, J. Schockmel, F. Francqui, N. Vandewalle, and G. Lumay, Annual Transactions of The Nordic Rheology Society 25, 17-21 (2016).

Influence of cohesives forces on the macroscopic properties of granular assemblies, G. Lumay, J. Fiscina, F. Ludewig and N. Vandewalle, AIP Conference Proceedings 1542, 995 (2013).

Linking compaction dynamics to the flow properties of powders, G. Lumay, N. Vandewalle, C. Bodson, L. Delattre and O. Gerasimov, Applied Physics Letters 89, 093505 (2006).

Linking flowability and granulometry of lactose powders, F. Boschini, V. Delaval, K. Traina, N. Vandewalle, and G. Lumay, International Journal of Pharmaceutics 494, 312–320 (2015).

Measuring the flowing properties of powders and grains, G. Lumay, F. Boschini, K. Traina, S. Bontempi, J.-C. Remy, R. Cloots, and N. Vandewall, Powder Technology 224, 19-27 (2012).

Motion of carbon nanotubes in a rotating drum: The dynamic angle of repose and a bed behavior diagram, S. L. Pirard, G. Lumay, N. Vandewalle, J-P. Pirard, Chemical Engineering Journal 146, 143-147 (2009).

Mullite coatings on ceramic substrates: Stabilisation of Al2O3–SiO2 suspensions for spray drying of composite granules suitable for reactive plasma spraying, A. Schrijnemakers, S. André, G. Lumay, N. Vandewalle, F. Boschini, R. Cloots and B. Vertruyen, Journal of the European Ceramic Society 29, 2169–2175 (2009).

Rheological behavior of β-Ti and NiTi powders produced by atomization for SLM production of open porous orthopedic implants, G. Yablokova, M. Speirs, J. Van Humbeeck, J.-P. Kruth, J. Schrooten, R. Cloots, F. Boschini, G. Lumay, J. Luyten, Powder Technology 283, 199–209 (2015).

The flow rate of granular materials through an orifice, C. Mankoc, A. Janda, R. Arévalo, J. M. Pastor, I. Zuriguel, A. Garcimartín and D. Maza, Granular Matter 9, p407–414 (2007).

The influence of grain shape, friction and cohesion on granular compaction dynamics, N. Vandewalle, G. Lumay, O. Gerasimov and F. Ludewig, The European Physical Journal E (2007).