News

Enhancing 3D Printing Precision: INFN's Experience with GranuDrum

INFN leverages GranuDrum's precision tools to enhance powder flow characterization, driving advancements in 3D printing accuracy and efficiency.

The National Institute for Nuclear Physics (INFN) is the Italian research agency dedicated to the study of the fundamental constituents of matter and the laws that govern them, under the supervision of the Ministry of Universities and Research (MUR). It conducts theoretical and experimental research in the fields of subnuclear, nuclear and astroparticle physics. All of the INFN’s research activities are undertaken within a framework of international competition and cooperation, in close collaboration with Italian universities on the basis of solid academic partnerships spanning decades. Fundamental research in these areas requires the use of cutting-edge technology and instruments, developed by the INFN at its own laboratories and in collaboration with industries.

Could you briefly detail the current projects conducted at INFN in the Additive Manufacturing Field?

INFN is currently working on several projects in the field of Additive Manufacturing; among them the development of innovative metal nanocomposites (powders mixture) in the Rome division and Gran Sasso National Laboratories through the HAMMER collaboration. This metal nanocomposite – called “Dragon Copper” for the implemented properties of the base material - are produced in INFN Rome laboratory and are currently patented. A specific project, INTEFF_2_DRAGON, has been funded by INFN and the European Union - Next Generation EU, through MIMIT and Invitalia, under the PoC PNRR 2022 call for proposals. The range of applications is quite broad, including the production of components for cryiogenic applications and heat exchangers

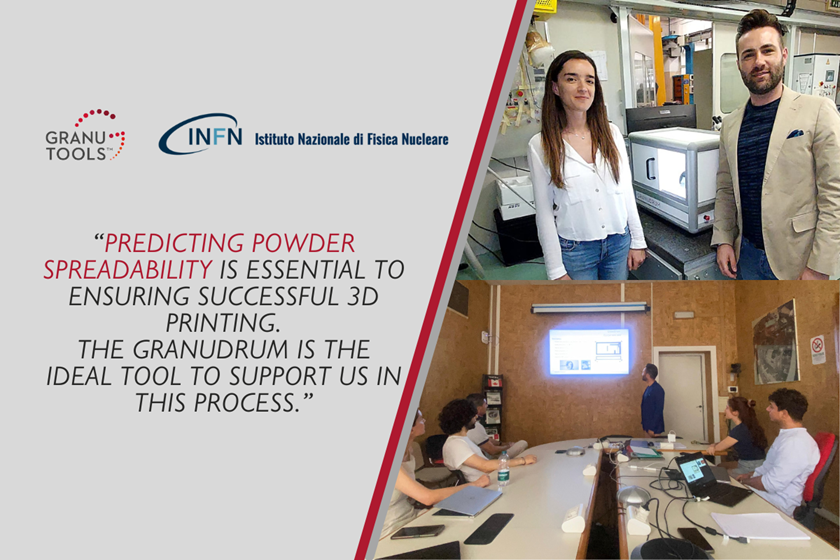

Ilaria Rago, INFN Research Engineer and Giuseppe Rosario Del Sorbo, Sales Manager at Granutools, at INFN lab

What is the importance of powder characterization in your research?

Powder characterization plays a crucial role in additive manufacturing - in particular for a new material - to ensure proper processability for a successful printing outcome. In our case, the materials we use could face flowability issues, which could negatively impact the printing process. As a result, accurate and e]ective material characterization is essential to predict how the powder will behave during the process.

Why Did you choose GranuDrum for your powder characterization?

In our ongoing research project, predicting powder spreadability is essential to ensuring successful 3D printing. The GranuDrum is the ideal tool to support us in this process. By providing the Cohesive Index, through its unique and innovative methodology, we can accurately predict spreadability even for a material like the Dragon Copper (where weak and secondary chemical bonds have an important effect) and optimize the parameters of the 3D printer. This approach is critical for us, both in scaling up powder production and in controlling key variables of the 3D printing, such as recoater speed, humidity, and temperature.

Seminar on Powder flow characterization held by Giuseppe Rosario Del Sorbo, Sales Manager at Granutools, at INFN