Application notes

How to evaluate powder caking with GranuPack

Powder caking is important for industrial applications. Learn how the GranuPack can measure the caking and investigate it thanks to this protocol.

Context

Caking can be detrimental to powder handling in many industrial processes.

Therefore, evaluating the ability of a powder to cake with an adequate tool and a defined protocol is of huge interest. We propose here a simple protocol for measuring the caking propensity using the powder packing dynamic evaluated with a GranuPack.

Want to learn why powder caking is an important phenomenon for industrial applications? Read our blog article.

Protocol

The investigation of caking can follow a specific protocol using the GranuPack. It involves preparing a powder sample, applying a load for a defined storage duration, and analyzing the powder's properties after storage. Repeating the procedure with varying storage times allows for the evaluation of the temporal evolution of caking. For the full protocol, please contact us.

Figure 1: Picture of the outside cells

LEARN MORE ABOUT THE GRANUPACK

Experimental results and interpretation

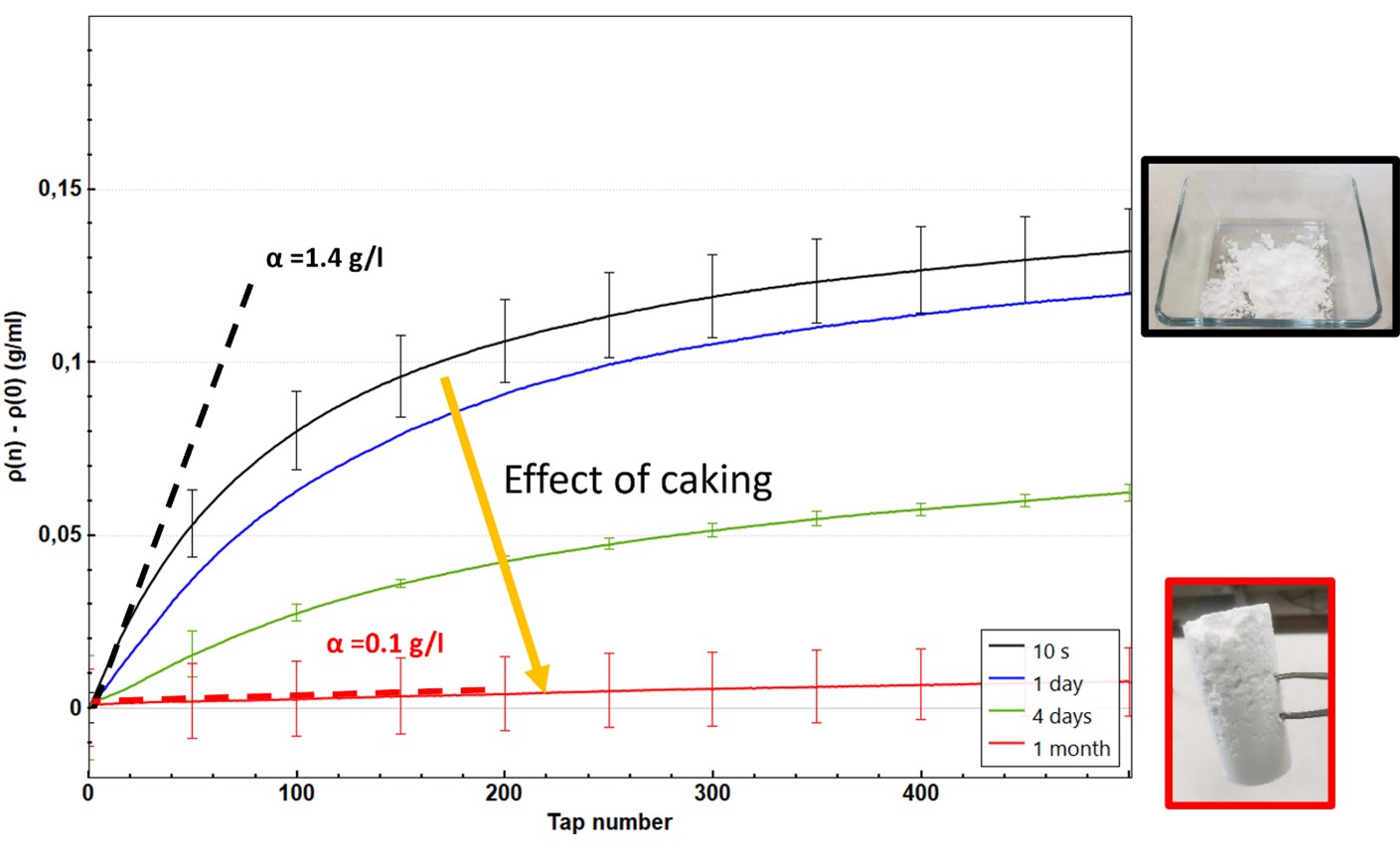

Figure 2 presents typical results obtained by following this protocol for a powder of fine sugar. The test with 10 seconds of Time of Storage can be considered as not caked and act as a reference. Thanks to the accuracy of the GranuPack, the drift in powder properties after 1 day is already visible.

Figure 2: Effect of the caking on the powder packing

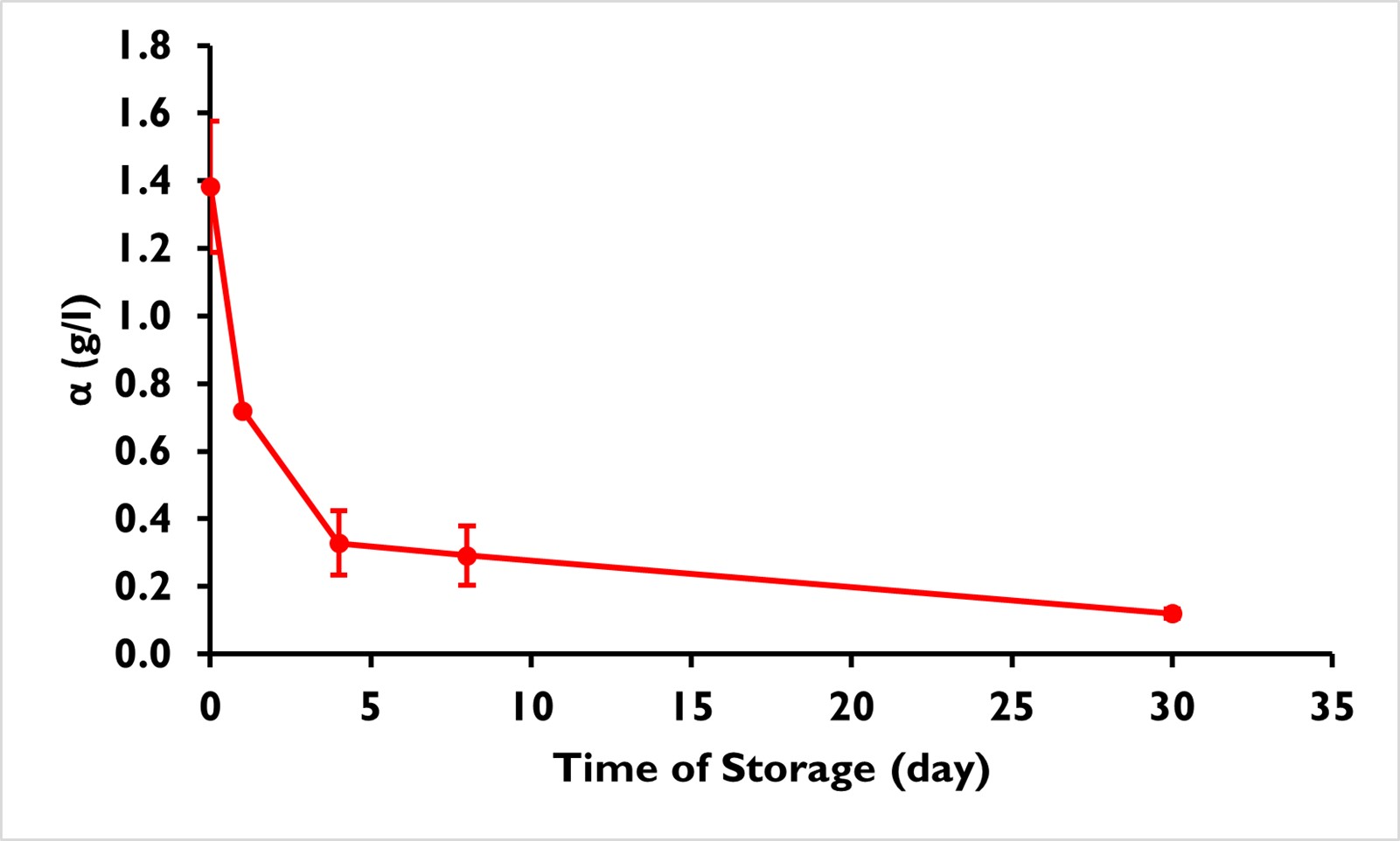

The packing dynamic of the powder is influenced by the caking. Indeed, the larger the Time of Storage the larger the formation of solid bridges due to caking mechanisms. These bridges decrease the mobility of the particles which can be quantified by the metric α [Lumay, Geoffroy, et al., Advanced Powder Technology 31, 4428-4435 (2020)]. Since particles need mobility to be reorganized during densification, the lower α the lower the particle mobility and thus the more caked the powder. Consequently, the metric decreases with the Time of Storage as the caking takes place. A fully caked powder will have α that tends to 0 g/l since the powder behaves like a solid and cannot densify. This can be observed after 1 month. Indeed, a decrease of one order in magnitude is obtained for α between 10 seconds and 1 month of Time of Storage and a solid block can be observed in the red insert.

Figure 3: Decrease in α with Time of Storage assessing the caking evolution

Conclusions

Thanks to the analysis of the powder packing dynamic α performed by the GranuPack, the evolution of caking with the Time of Storage can be measured. The cell of the GranuPack can be removed from the instrument and can be placed in various conditions (humidity, temperature, pressure on the top of the powder column) during different Times of Storage. This allows a wide and easy investigation of the effect of conditioning parameters on caking. Applying steps (1)-(5) by varying these parameters will path the way of caking investigation with a repeatable and accurate method.