News

GranuDrum High Temperature: Transforming Powder Flowability Analysis at Elevated Temperatures

Granutools is proud to announce the launch of the GranuDrum High Temperature (HT), a cutting-edge instrument enabling the precise analysis of powder flowability and cohesion at temperatures reaching up to 250°C.

Introduction: Granutools Unveils the GranuDrum High Temperature

Granutools is proud to announce the launch of the GranuDrum High Temperature (HT), a cutting-edge instrument enabling the precise analysis of powder flowability and cohesion at temperatures reaching up to 250°C. By simulating high-temperature conditions, the GranuDrum HT provides a more accurate understanding of powder behavior, meeting the critical needs of industries like Additive Manufacturing (AM) where material performance at elevated temperatures directly impacts product quality.

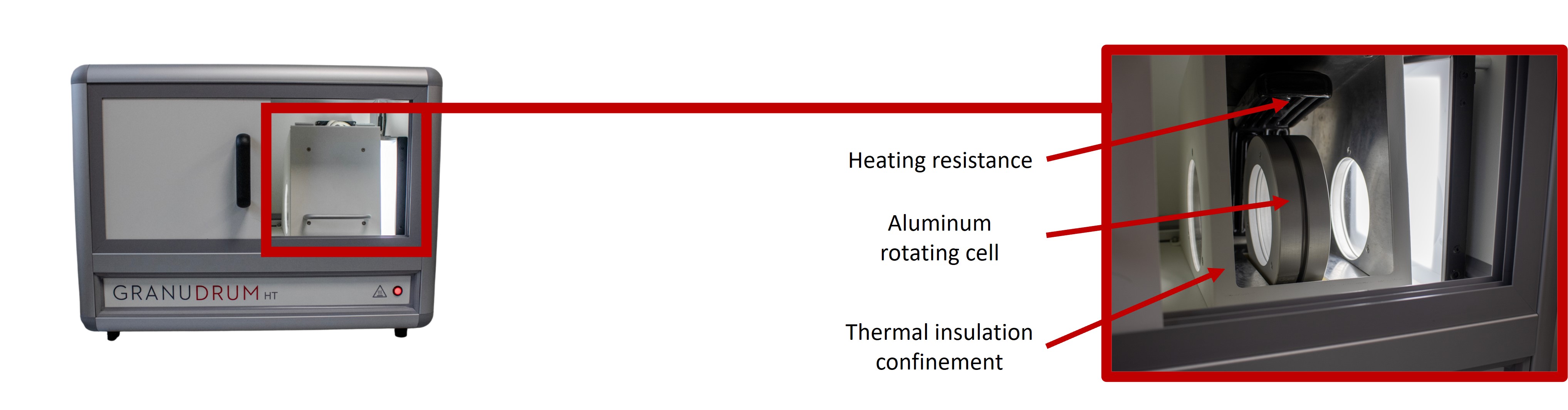

Integrated Heating Solution and Precise Temperature Control

GranuDrum HT allows measurements across a wide temperature range (from room temperature up to 250°C), ideal for high-temperature applications. Its integrated heating system pre-heats powders directly within the measurement cell, eliminating the need for external equipment. The internal heating resistance ensures that the cell reaches and maintains the desired temperature, which is constantly monitored and adjusted by an inbuilt sensor and software, providing operators with exact temperature control for reliable and reproducible results.

Flowability Measurement with Cohesion Analysis

GranuDrum HT is equipped with a rotating drum half-filled with powder and vertical glass side walls, allowing a high-resolution camera to capture the fluctuations of the powder interface. These fluctuations are then analyzed to calculate the Cohesive Index (CI) as a function of the drum speed. By observing CI variations at different temperatures, users can gain valuable insights into the rheological behavior of powders, furthering their understanding of material cohesion under high thermal conditions.

Optimized Thermal Conductivity for Accuracy

With a high-conductivity, heat-resistant glass measurement cell, GranuDrum HT minimizes temperature gradients, optimizing data accuracy. This design ensures that powder samples are evenly heated, providing reliable measurements crucial for applications where small changes in powder behavior can have significant effects on production quality.

Real-Time Temperature Monitoring for Operator Confidence

The GranuDrum HT’s software interface provides real-time temperature tracking, allowing users to monitor and adjust the cell temperature continuously throughout each measurement. This feature ensures complete process transparency, giving operators confidence in the data’s accuracy and reliability.

Experience the GranuDrum HT Live at Formnext 2024

Granutools will showcase the GranuDrum High Temperature at Formnext 2024, held in Frankfurt, Germany, from November 19-22. Visitors are invited to witness live demonstrations of the instrument at Granutools’ booth 11.0 D42. This event provides an exclusive opportunity for attendees to experience firsthand the capabilities of the GranuDrum HT and discuss its applications with Granutools’ experts. Contact us to claim your free pass!

CONTACT US TO CLAIM YOUR FREE PASS

Advanced Powder Flowability Insights in Additive Manufacturing

The GranuDrum HT has already demonstrated its effectiveness through tests on different powders commonly used in AM, revealing how temperature variations affect each material uniquely. This investigation highlighted the importance of analyzing powders at realistic thermal conditions, as cohesion changes with temperature can significantly alter powder spreadability, directly influencing the quality of the powder layer in processes like powder bed fusion. Relying solely on room-temperature measurements could lead to erroneous assumptions and potentially compromise AM quality.

Conclusion

The impact of temperature on powder cohesion is clearly demonstrated through GranuDrum HT’s precise temperature control, which reveals behaviors that would remain unnoticed at room temperature. This insight is crucial for AM and other industries where manufacturing conditions differ significantly from ambient conditions.

Granutools continues to push the boundaries of powder characterization, providing tools that help industries achieve unparalleled accuracy and consistency. To experience the GranuDrum High Temperature firsthand, visit Granutools at Formnext 2024, booth 11.0 D42.