Ceramics

GranuCharge: The New Powder triboelectric charger

The Granucharge measures the ability of a flowing powder to charge electrostatically by allowing the powder to flow under the influence of gravity and measuring the electrostatic charge of the powder.

The GranuCharge measures the ability of a flowing powder to charge electrostatically by allowing the powder to flow under the influence of gravity and measuring the electrostatic charge of the powder.

Electrostatic charges are created inside a powder during a flow. This apparition of electric charges is due to the triboelectric effect, which is a charge exchange at the contact between two solids.

LEARN MORE ABOUT THE GRANUCHARGE

During the flow of a powder inside a device, such as a mixer, a silo or a conveyor, the triboelectric effect takes place at the contact between the solid powder particles and at the contact surface between these particles and the device. In particular, triboelectric effect takes place when two particles are sliding on each other or when a particle is sliding on a surface or when a particle impacts an other particle or when a particle impacts a surface.

Therefore, the characteristics of the powder and the properties of the material used to build the device are important parameters. The apparition of electric charges inside a powder can produce sparks and cause explosion hazards. In addition, the electrostatic charging during powder particle flow induces agglomeration and segregation which may cause dosage problems.In some applications, the apparition of electric charges inside a powder is an advantage. The best-known application based on powder electrification is the electrophotography. The powder coating process is also based on the adhesion of charged powder particles onto a surface.

In granular mixtures, the dependence of the electrification on the powder particles is interesting in separation techniques.In order to optimize the processes used in these applications, a method and measurement devices are used to measure the ability of a powder to be electrostatically charged. Such methods and devices may be advantageously used to test the effect with respect to the electrostatic charge of an antistatic additive, the effect of the different powder characteristics and/or the effect of the material of the above referred to device.

Measuring the electrostatic charge of the powder as discharged from the conduit in the method is suitably performed in a so-called Faraday cup. Preferably the charged powder falls into such a Faraday cup positioned below a discharge opening in the conduit. When a certain amount of powder is collected in the Farady cup the total value of the electric charge Q. present in the collected powder is measured by means of an electrometer. Suitably the electrometer is optimized for the measurement of charged powders, wherein the measurement range is suitably between from 10″10C to 10″6C. Optionally, this charge expressed in Coulomb is divided by the sample powder mass M of the collected powder to obtain a charge density q expressed in Coulomb per kilogram. The sample powder mass may be known upfront or more suitably the weight of the powder as discharged into the Faraday cup is measured.

The temperature, pressure and humidity at which the method is performed may be chosen to mimic the actual conditions of for example the commercial device in which the powders will eventually be used. For example the relative air humidity and the ambient temperature are well known in the art to influence the flowing properties of powders and their ability to be electrostatically charged.

Therefore, some industrial processes involving powder are sensitive to the meteorological conditions. The modification of the powder flowing properties due to humidity variations is mainly related to the electric charges present inside the powder.A low relative humidity strengthens the triboelectric effect while high relative humidity leads to a dissipation of the electric charges. It has been found that the method and measurement device according to the invention is very suitable to quantify this complex effect at different hygrometric conditions.

LEARN MORE ABOUT THE GRANUCHARGE

Example A

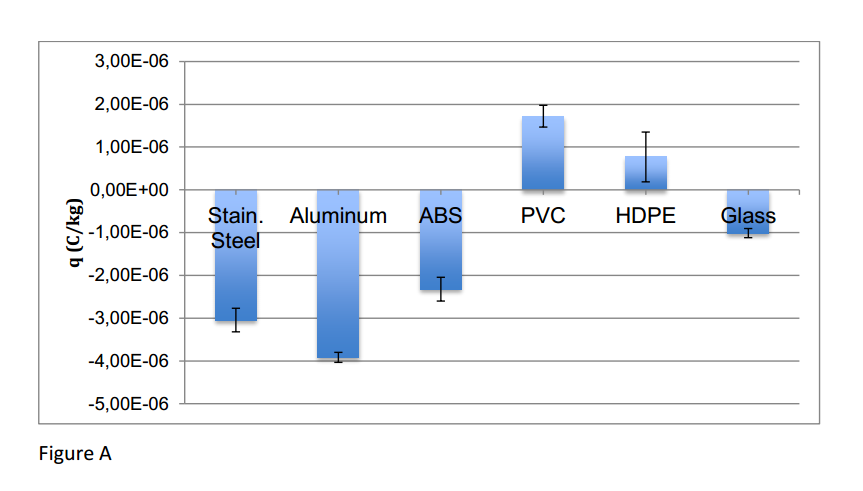

The test was repeated with different tube materials: Stainless Steel 316L, Aluminum 6063-T6, borosilicate glass, ABS, PVC and HDPE. The figure A represents the charge density inside the sample after the flow in the V-tube for the different tube materials.These results show that the amount and the sign of the powder charge will depend strongly on the tube material.

Therefore, the choice of the tube material is critical while performing a powder charging measurement aimed at predicting the properties of the powder in a commercial device.

Example B

In this example the effect of an antistatic additive was investigated. Practical problems related to an excessive presence of electric charges inside a powder are commonly solved by the addition of an anti-static additive.

Therefore, the best additive has to be selected.Indeed, the nature of the additive depends on the powder properties.

After the additive selection process, the more efficient quantity of additive has to be determined. Performing a series of trial and error tests on a production line is usually too expensive and sometimes practically impossible.

LEARN MORE ABOUT THE GRANUCHARGE

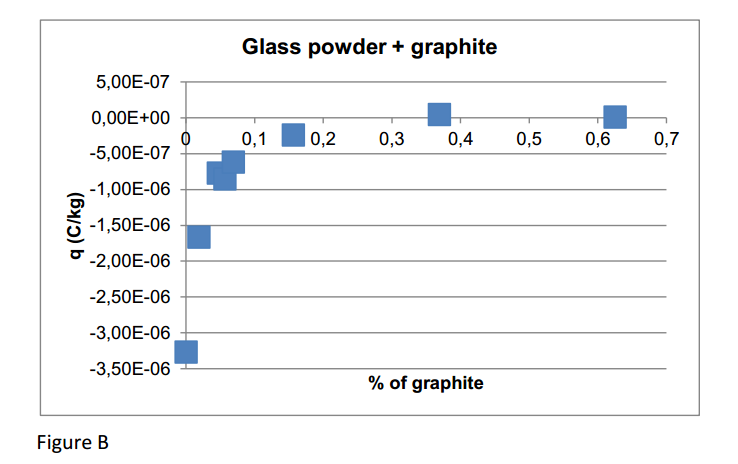

Therefore, a laboratory measurement device according to the present invention is necessary to perform this selection and the dosage. Example 4 was repeated with a stainless steel 316L V-tube except that different amounts of fine graphite powder as the antistatic additive was added to the powder. Figure B shows the evolution of the electric charge quantity created inside a glass powder during a flow as a function of the quantity of an antistatic additive.

Figure B

The effect of the additive on the electric charging process is well demonstrated by the present invention. Indeed, a small percentage in mass of this additive decreases drastically the quantity of electric charges present in the powder after the flow. This curve of Figure B allows to validate or invalidate the selection of the additive.

Moreover, the curve allows to select the correct amount of additive in accordance with the practical constrains.In the present case, 0.2% of graphite is sufficient to prevent the apparition of triboelectric charges.

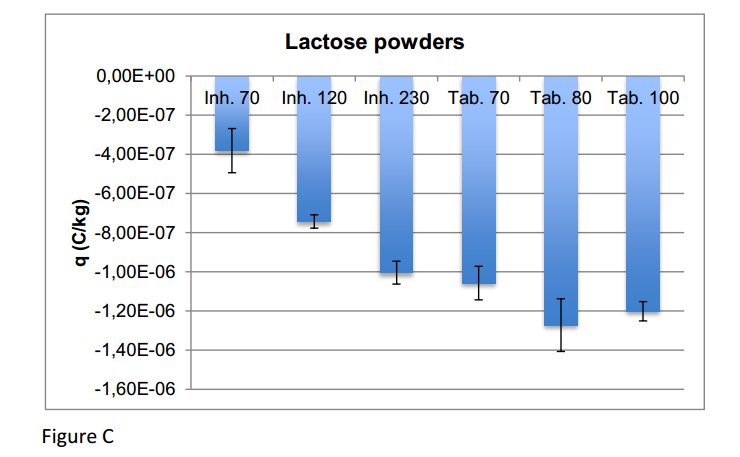

Example C

In this Example, we show how the powder electrometer can be used to solve practical problems. The effect of a choice in lactose powders is investigated. Lactose powders are commonly used as excipients for dry powder pharmaceutical formulations.Indeed, the lactose is inert, non-toxic and cheap.

Therefore, any progress in the understanding of lactose powders behaviors could have huge consequences for pharmaceutical industries. The lactose grains considered in this study are used in dry powder inhaler (DPI) applications or to make tablets. These powders are produced by Meggle under the names InhaLac® 70, InhaLac® 120, InhaLac® 130, Tablettose® 70, Tablettose® 80 and Tablettose® 100. Example 5 was repeated except that instead of the glass powder different lactose powders are measured. Figure 9 shows the charge density inside the sample after the flow in the V-tube for the different lactose samples. The different InhaLac® powders used in this study have different granulometries.For InhaLac® 70, InhaLac® 120 and InhaLac® 130, the average grain size are respectively d50=207 micrometers, d50=132 micrometers and d50=99 micrometers.

LEARN MORE ABOUT THE GRANUCHARGE

As shown by the present results, the granulometry seems to influences the amount of charges created inside the powder during a flow. At the opposite, the Tablettose® powders used in this study have similar granulometries. Therefore, the triboelectric characteristics of these Tablettose® powders are also close to each other.