Chemicals

Fast and easy determination of the flow-ability and the cohesion of granular materials: clay, flour, lactose, polymeric and metallic powders

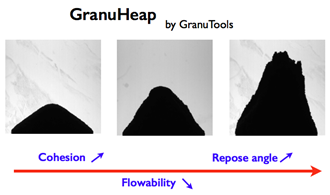

When a powder is poured onto a surface, a heap is formed. It is well known that both the repose angle and the heap shape strongly depend on grain properties. In particular, a cohesive powder forms an irregular heap while a non-cohesive powder forms a regular conical heap...

When a powder is poured onto a surface, a heap is formed. It is well known that both the repose angle and the heap shape strongly depend on grain properties. In particular, a cohesive powder forms an irregular heap while a non-cohesive powder forms a regular conical heap.

Therefore, a precise measurement of the heap shape provides useful information about the physical properties of the powder sample.precise measurement of the heap shape provides useful information about the physical properties of the powder sample.

The GranuHeap instrument is an automated heap shape measurement method based on image processing and analysis. A powder heap is created on a cylindrical support.

In order to obtain reproducible results, an initialization tube with an internal diameter equal to the circular support is installed on the support. After filling the initialization tube by hand with a fixed volume of powder (typically 100 ml), the tube goes up at the constant speed.

Thereby, the powder is flowing from the tube to form a heap on the cylindrical support. A controlled rotation of the support allows obtaining different heap projections corresponding to different heap orientations. A custom image recognition algorithm determines the position of the powder/air interface.

LEARN MORE ABOUT THE GRANUHEAP

The repose angle refers to the angle of the isosceles triangle with the same surface than the powder heap projected image. This isosceles triangle corresponds to the ideal cohesiveness heap shape. The repose angle is computed for each image, i.e. for each heap orientation. Afterwards, an average value is computed.

In general, the lower the repose angle is, the better the powder flowability is. The deviation between the real heap interface and the isosceles triangular heap provides the static cohesive index.This index is close to zero for a non-cohesive powder and increases when the cohesive forces inside the powder strengthen.

The next Table summarizes the empirical relation between the results obtained with the GranuHeap instrument and powder flowability.

| Flow | Repose Angle (°) | Static Cohesive Index |

| Excellent | 25-30 | < 0.2 |

| Good | 31-35 | 0.3 - 0.5 |

| Fair | 36-40 | 0.6 - 0.8 |

| Passable | 41-45 | 0.9 - 1.2 |

| Poor | 46-55 | 1.3 - 1.7 |

| Very Poor | 56-65 | 1.8 - 2.4 |

| Very very poor | > 66 | > 2.5 |

Figure 1 shows two heaps of sugar

While the granular sugar forms a classical conical heap, the powdered sugar forms a strongly irregular heap.

Contrary to the granular sugar, the powdered sugar is strongly cohesive due to the small size of the grains. This example clearly shows that the heap shape strongly depends on the grain properties. In particular, a cohesive granular material gives a high value of the repose angle and strong deviations from the conical shape.

LEARN MORE ABOUT THE GRANUHEAP

Therefore, a precise measurement of the heap shape gives some useful information about interactions between the grains.

The angle of repose test is very sensitive to the method used to create the heap. Therefore, an initialization protocol has to be defined.

Moreover, after the heap formation, the measurement of the repose angle is not obvious.

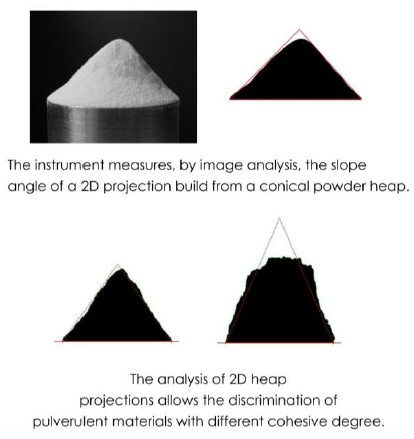

As shown in Figure 2, the shape of the heap has to be analysed carefully.

Figure 1 : Two typical heap shapes

(a) Conical heap shape obtained with a non cohesive granular sugar.

(b) Irregular heap of powdered sugar which is a cohesive granular material [1].

Figure 2

(a) heap of powder on the GranuHeap support,

(b) projection of the heap of powder

(c) comparison between two powders: non-cohesive and cohesive powder.

Therefore, the classical method which consists in measuring the heap height h on a circular support of diameter ø and in calculating the angle with the relation tan(α)=2h/ ø is subject to caution. For our measurements, an initialization tube with an internal diameter equal to the support diameter is placed on the support.

LEARN MORE ABOUT THE GRANUHEAP

After filing manually the tube with the sample of powder, the initialization tube goes up at a constant speed of 5 mm/s. Therefore the powder flows from the tube to form a heap on the cylindrical support (see Figure 2a) and the handling of the powder by the operator is erased.

This support can rotate slowly around its axis. Then, a CCD camera is able to take pictures of the heap for different orientations.

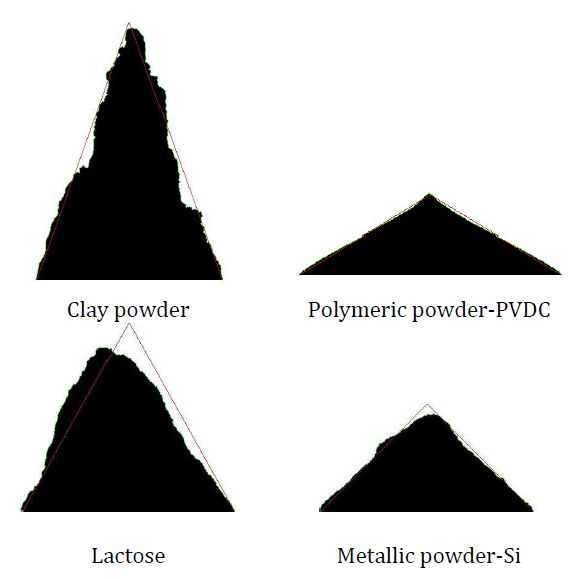

To obtain the results presented in the next sections, 16 images separated by a rotation of 11,25° were recorded. In this way, even if the heap shape is complex and asymmetric (clay, lactose, flour powders with high cohesion), we are able to extract all the geometrical information.

From each picture of the heap, a dedicated algorithm finds the position of the interface powder/air by image analysis (fig.2b). The repose angle αr is the angle of the isosceles triangle which has the same surface area as the heap. The isosceles triangle corresponds to the ideal heap shape.

We can observe in table 1 that a large range of powders (free flowing to high cohesive) can be analyzed by using the GranuHeap instrument. This technique can be used for having good and rapid information on the rheological behavior of your material.

LEARN MORE ABOUT THE GRANUHEAP

The GranuHeap instrument can be used for quality control due to its fastness (less than 1 minute for one complete analysis) and its high degree of automation (easy to perform).

Moreover, the analysis report is generated to ensure the traceability of your test. This new instrument can also be used in R&D process for developing new formulations or to study the effect of an additive (nature, amount…) in your powder.

At every time, you are able to observe in live your measurements (heap rotation) and after the analysis, you can recover the images linked to these analysis (fig.3).

| Materials | αr Repose Angle (°) |

σr Cohesive Index |

Height Heap (mm) |

Flow Properties |

| Clay | 71.7 | 2.3 | 53.2 | very very poor |

| Polymer | 33.7 | 0.1 | 14.6 | good |

| Lactose | 56.4 | 1.4 | 27.9 | very poor |

| Metallic | 43.8 | 0.2 | 17.9 | passable |

| Flour | 66.4 | 2.1 | 48.4 | very poor |

Table 1: experimental values obtained for different materials tested with the GranuHeap instrument

Figure 3 : projection of the heap of powder obtained with the GranuHeap instrumentComparison between four powders: clay, polymer, lactose and metallic powders

LEARN MORE ABOUT THE GRANUHEAP

References

[1] Measuring the flowing properties of powders and grains,G. Lumay, F. Boschini, K. Traina, S. Bontempi, J.-C. Remy, R. Cloots, N. VandewallePowder Technology, Volume 224, July 2012, Pages 19-27