Ceramics

GranuDrum : The New Rheometer for Powder

The Granudrum instrument has been developped to measure the dynamic flow properties of a powder for different rotating speed Ω. Therefore, the flowability is measured as a function of the shearing rates and rheological properties like shear thinning or shear thickening could be evaluated...

Experimentally, the most practical geometry to study the flow of granular materials is the rotating drum. This flow geometry has already been scientifically studied. The GranuDrum instrument has been developped to measure the dynamic flow properties of a powder for different rotating speed Ω.

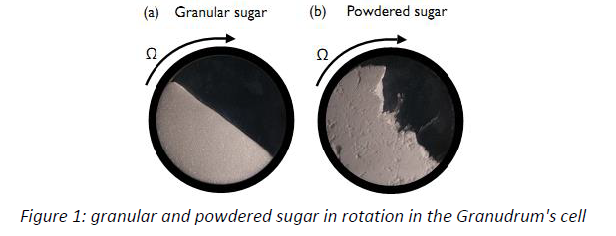

Therefore, the flowability is measured as a function of the shearing rates and rheological properties like shear thinning or shear thickening could be evaluated. Moreover, The GranuDrum allows to determine the first avalanche angle (yield point) and the ratio between the volume of the powder rotating at a fixed speed and the powder at rest, typically V0/Vt which gives information powder aeration and caking. The flow of a non-cohesive and cohesive powder in a rotating drum is presented in figure 1. The non-cohesive powder gives a regular flow with a low value of the flowing angle (Fig.1 a) while the flow of the cohesive powder is irregular with a higher average flowing angle (Fig.1 b).

LEARN MORE ABOUT THE GRANUDRUM

Figure 1: Granular and powdered sugar in rotation in the cell of the GranuDrum instrument

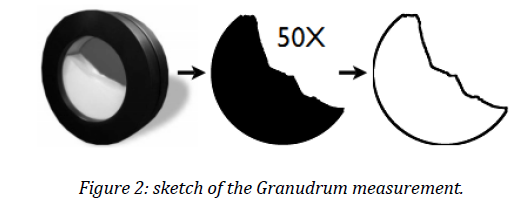

The experimental set up ( see figure 2 ) is a horizontal aluminum cylinder with glass side walls (10 to 100 cm3). The drum is half-filled with the powder. The cylinder rotates around his axis at an angular velo city Ω producing the flow of the grains.

To perform the measurements, the rotating drum is backlighted and recorded with a CCD camera.

For each angular velocity, 50 images of the drum separated by 0.5 s are recorded. On the images, the granular material appears in black while the air appears in white. Then, the position of the air/powder interface is determined by an edge detection.

The average interface position and the fluctuations around this average position are computed. From the fluctuations of the interface, the standard deviation (σf) is calculated. This parameter is directly related to the cohesion inside the drum. Indeed, considering a rotating speed Ω, a non- cohesive granular material leads to a continuous flow. From the average interface position, the flowing angle (αf) is measured in the center of the flow.

Figure 2: sketch of the GranuDrum instrument

LEARN MORE ABOUT THE GRANUDRUM

The GranuDrum rheometer for powder allows:

- to classify the samples in terms of flowability and cohesion;

- to characterize the behavior of the samples under motion;

- to quantify the main effects observed when the powder is in motion.

Figure 3A shows the flow curves for 3 typical materials obtained with the GranuDrum instrument: polymer, flour and lactose powders. We can observe that these three samples have very different rheological behavior (table 1).

Polymeric powder is independent on the rotating speed. The flow curve (blue) is stable in all the rotating speed studied. The flow-ability of the flour depends on the rotating speed. The corresponding flow curve (red) decreases with the rotating speed (shear thinning behavior). So, the highest the rotating speed goes, the best flow-ability we get. The contrary is observed for lactose powder. The lactose flow curve (black) increases with the rotating speed (shear thickening). Thus, we are able to know the effect of the rotation motion on the flowability and the cohesion of the powders.The different behaviors observed (figure 3A) are due to different physical and chemical characteristics of the particles (nature, density, size, shape, roughness, …).

Figure 3A shows that it is also possible to extract from the results a cohesion index which allows to follow the evolution of the cohesion in the powder as function of the rotating speed. This cohesive index allows to follow the evolution of the cohesion between grains of powder and to make comparison before and after material treatment (addition of binders, flowing agent, surface coating or effect of the relative humidity).

| Powders | Flowability (6 rpm) | Rheological behavior |

|---|---|---|

| Polymer | High | Stable/independant/plastic |

| Lactose | Middle | Increasing/shear thickening or dilatant |

| Flour | Low | Decreasing/shear thinning or pseudoplastic |

Table 1: main characteristics of the samples analyzed with Granudrum instrument (flowability classification and rheological behavior)

and cohesive index curves (B) recorded as function of the rotation speed for polymer, flour and lactose powders.png)

Figure 3: flow curves (A) and cohesive index curves (B) recorded as function of the rotation speed for polymer, flour and lactose powders

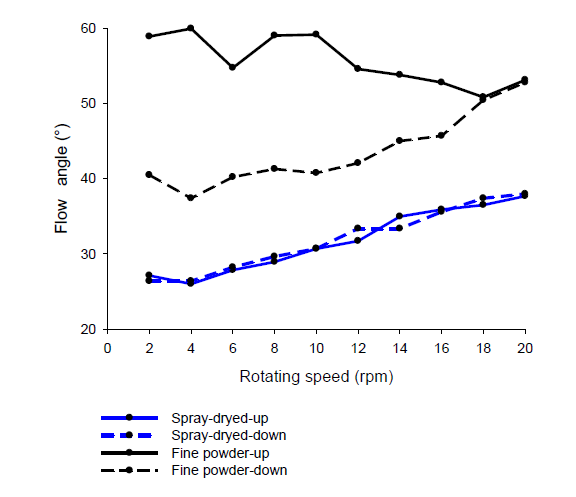

Figure 4 shows two complete flow curves obtained for ceramic powders (fine and spray-dryed Al2O3/SiO2 powders).

In this case, The controlled rotating speed mode was used to measure the flow curve with a two stage measuring program with a linear increase of rotating speed from 0 to 20 rpm (up curve) and a decrease to zero rotating speed (down curve).

LEARN MORE ABOUT THE GRANUDRUM

The thixotropy of the blend is measured by the hysteresis area

enclosed between the up and down curves. We can observe that fine powders (black curves) is characterized by a high thixotropy. So, the behavior of the powder is modified due to the rotation motion. This is due to the special properties of the material (submicronic powders). Although, the spray-dryed powder is not characterized by an hysteresis. So, the handling of this powder has no effect in time.

Figure 4: complete flow curves with hysteresis mode measurement obtained with the Granudrum instrument for submicronic and spray-dryed blends of Al2O3/SiO2 powders