Application notes

GranuFlow: Improved Laboratory Silo: Comparison vs Hall Flowmeter

The GranuFlow is a straightforward powder flowability measurement device composed of a silo with different apertures associated with a dedicated electronic balance to measure the flowrate...

Introduction

Theoretical Framework

Granular materials and fine powders are widely used in industrial applications. To control and to optimize processing methods, these materials have to be precisely characterized. The characterization methods are related either to the properties of the grains (granulometry, morphology, chemical composition, …) and to the behaviour of the bulk powder (flow-ability, density, blend stability, electrostatic properties, …).

However, concerning the physical behaviour of bulk powder, most of the techniques used in R&D or quality control laboratories are based on old measurement techniques. During the last decade, we have updated these techniques to meet the present requirements of R&D laboratories and production departments. In particular, the measurement processes have been automatized and rigorous initialization methods have been developed to obtain reproducible and interpretable results. Moreover, the use of image analysis techniques improves the measurements precision.

A range of measurement methods has been developed to cover all the needs of industries processing powders and granular materials. However, in this application, we will focus on the GranuFlow instrument.

GranuFlow

The GranuFlow is an improved laboratory silo compared to the ancient Hall Flow Meter (ASTM B213, ISO4490) and compared to the “Flow Through An Orifice” method described in the Pharmacopea (USP1174).

The GranuFlow is a straightforward powder flowability measurement device composed of a silo with different apertures associated with a dedicated electronic balance to measure the flowrate. This flowrate is computed automatically from the slope of the mass temporal evolution measured with the balance. The aperture size is modified quickly and easily with an original rotating system. The measurement and the result analysis are assisted by software. The flowrate is measured for a set of aperture sizes to obtain a flow curve.

LEARN MORE ABOUT THE GRANUFLOW

Finally, the whole flow curve is fitted with the well-known Beverloo theoretical model to obtain a flowability index (Cb, related to the powder flowability) and the minimum aperture size to obtain a flow (Dmin) (for theoretical background, user can refer to Appendix 1). The whole measurement is performed easily, fastly and precisely. In this paper, we used a complete set of hole diameters: 4, 6, 8, 10, 12 and 14mm.

The main purpose of this application note is to provide information about the measurements reproducibility with the GranuFlow and to show some examples about what is it able to offer. In a second part, a comparison between the two instruments is presented in order to show the advantage of using the GranuFlow.

Results reproducibility

Material

The powder used is made of Stainless-Steel 316L and the analysis were performed at 26°C and 40.0%RH (w = 8.5gH20/kgDryAir). Flowrate experiments have been repeated 5 times to show measurements accuracy. F is the powder flowrate (in g/s) and Cb the Beverloo parameter (in g/mm3). Dmin was not displayed here, since this minimum hole size is close to zero.

| Powder Flowrate F (g/s) | Standard Deviation | Average Beverloo's law | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Hole Diameter (mm) | Meas. 1 | Meas. 2 | Meas. 3 | Meas. 4 | Meas. 5 | Average F (g/s) | Std | Std/Av (%) | Hole Diameter (mm) | F (g/s) |

| 4 | 5.99 | 6.08 | 5.44 | 5.28 | 5.25 | 5.61 | 0.4 | 7.1 | 0 | 0.00 |

| 6 | 18.34 | 17.04 | 16.83 | 15.26 | 15.84 | 16.66 | 1.2 | 7.1 | 4 | 6.14 |

| 8 | 37.02 | 34.88 | 35.11 | 35.51 | 34.69 | 35.44 | 0.9 | 2.6 | 6 | 17.22 |

| 10 | 65.10 | 62.80 | 61.91 | 60.71 | 61.48 | 62.40 | 1.7 | 2.7 | 8 | 35.66 |

| 12 | 98.60 | 97.11 | 98.78 | 97.60 | 95.31 | 97.48 | 1.4 | 1.4 | 10 | 62.62 |

| Cb | 2.02 10-3 | 1.98 10-3 | 2.09 10-3 | 2.11 10-3 | 1.99 10-3 | 2.04 10-3 | 5.87 10-3 | 2.9 | 12 | 99.11 |

Table 1: Powder Flowrate F versus holes diameter. Reproductibility highlights

This table gives information about the results reproducibility with the knowledge of the Standard Deviation (std), which is better with high hole diameter (Accuracy close to 2%). The Cb parameter (linked to powder flow-ability) is also displayed (with great accuracy, approximately 2%.

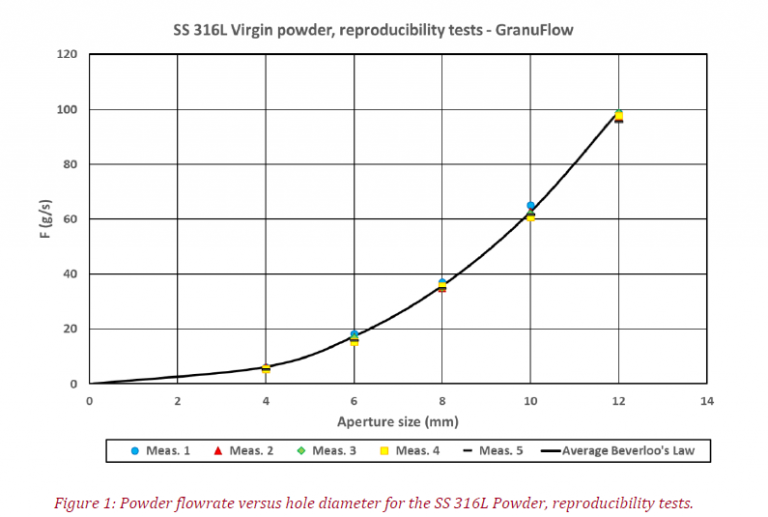

Once these results obtained, Flow rate versus hole diameter is plotted. The Beverloo law displayed is calculated with the average Cb coefficient:

Figure 1: Powder flowrate versus hole diameter for the SS 316L Powder, reproducibility tests

As we can see, the measurements of the GranuFlow show great accuracy, it is almost impossible to differentiate one test to another. Moreover, with the Beverloo law, the full mass flow rate curve is obtained and allow user to make data interpolation.

LEARN MORE ABOUT THE GRANUFLOW

GranuFlow versus Hall Flowmeter

In this part, the comparison between the Hall Flowmeter and the GranuFlow has been studied.

The SS 316L powder was investigated, but this time a comparison has been made between the Virgin and Recycled version of this product. Every test was conducted under the same absolute moisture condition (w = 7.5gH20/kgDryAir) Regarding the Hall Flowmeter experimental protocol, tests have been repeated five times with approximately the same powder mass (cf. Table 2).

SS 316L Virgin Powder

| HR (%) | T (°C) | Δt (s) | Δm (g) |

|---|---|---|---|

| 36.7 | 25.1 | 2 | 0.02 |

| Test n° | m (g) | t (s) | F (g/s) | ΔF (g/s) |

|---|---|---|---|---|

| 1 | 231.92 | 101.87 | 2.276627074 | 0.044893042 |

| 2 | 231.55 | 103.14 | 2.245006787 | 0.043727105 |

| 3 | 238.32 | 106.16 | 2.244913338 | 0.042481412 |

| 4 | 238.23 | 106.45 | 2.23795209 | 0.042234891 |

| 5 | 238.22 | 106.31 | 2.240805192 | 0.042344186 |

| Average Values | 235.648 | 104.786 | 2.249060896 | 0.043136127 |

SS 316L Recycled Powder

| HR (%) | T (°C) | Δt (s) | Δm (g) |

|---|---|---|---|

| 36.3 | 25.2 | 2 | 0.02 |

| Test n° | m (g) | t (s) | F (g/s) | ΔF (g/s) |

|---|---|---|---|---|

| 1 | 231.62 | 104.67 | 2.212859463 | 0.042473669 |

| 2 | 231.38 | 104.13 | 2.222030155 | 0.042870069 |

| 3 | 231.34 | 104.75 | 2.20849642 | 0.042357927 |

| 4 | 231.33 | 104.4 | 2.215804598 | 0.042639935 |

| 5 | 231.3 | 104.68 | 2.209591135 | 0.042407167 |

| Average Values | 231.394 | 104.526 | 2.213756354 | 0.042549753 |

Table 2: Hall Flowmeter results for SS 316L Powder (Virgin and Recycled)

The next table concerns raw results obtained with the GranuFlow instrument for the virgin and recycled powders, Dmin and Cb parameters are displayed as well.

SS 316L Virgin Powder

| GranuFlow - SS316L Virgin Powder | Dmin (mm) | Cb (g/mm3) | ||||

|---|---|---|---|---|---|---|

| 1.62 | 3.29E-03 | |||||

| Aperture Size (mm) | 4 | 6 | 8 | 10 | 12 | 14 |

| F (g/s) | 5.61 | 14.75 | 33.58 | 65.2 | 110.92 | 177.14 |

| SS 316L Virgin - Beverloo's Law (g/s) | 2.84 | 13.06 | 33.46 | 66.18 | 113.03 | 175.60 |

SS 316L Recycled Powder

| GranuFlow - SS316L Recycled Powder | Dmin (mm) | Cb (g/mm3) | ||||

|---|---|---|---|---|---|---|

| 1.17 | 2.84E-03 | |||||

| Aperture Size (mm) | 4 | 6 | 8 | 10 | 12 | 14 |

| F (g/s) | 5.37 | 15.44 | 33.57 | 64.7 | 108.58 | 166.48 |

| SS 316L Recycled - Beverloo's Law (g/s) | 3.80 | 14.46 | 34.36 | 65.29 | 108.75 | 166.10 |

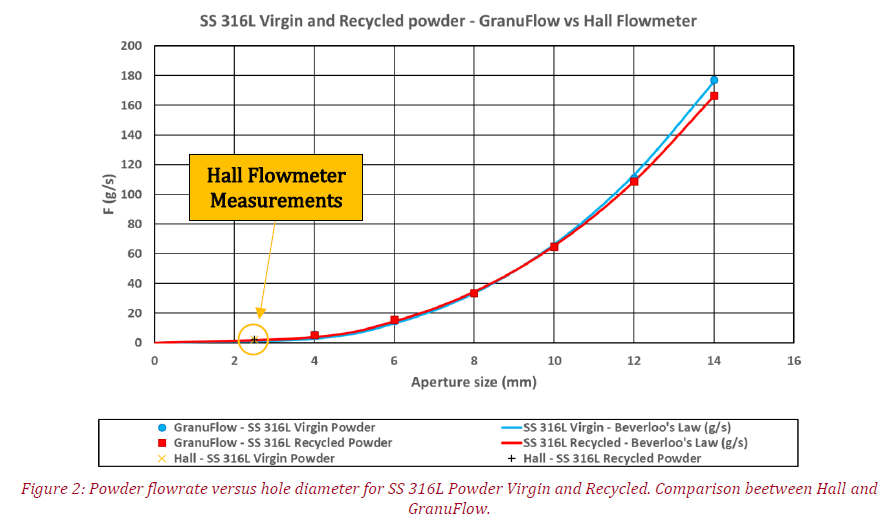

Once this step complete, the average valuesof powders flowrate (for Hall Flowmeter) were selected to be plotted and compared with those obtained by the GranuFlow(error bars are displayed in this Figure, but they are toosmall to be visible).

Figure 2: Powder flowrate versus hole diameter for SS 316L Powder Virgin and Recycled. Comparison beetween Halland GranuFlow

Those results are very interesting, they allow us to see that the GranuFlow and the Hall Flowmeter show similar results (according to Beverloo Law modelling).

LEARN MORE ABOUT THE GRANUFLOW

However, some differences can be highlighted. First, although both instruments results can be correlated, the Hall Flowmeter only gave us data for one diameter, while the GranuFlow allows to fully characterize the powder with a lot different holes diameter.

Moreover, the Hall Flowmeter can make no difference between those two samples, while the GranuFlow shows (both with Cb parameter and curves analysis) that SS 316L virgin powder has a slightly better flowability than the recycled one.

Conclusions

- The GranuFlow reproduces the Hall Flowmeter results;

- The GranuFlow allows to plot the full mass flow rate curve, while the Hall Flowmeter only gives the mass flow rate measurement for one diameter;

- The GranuFlow provides powder flow-ability measurements with the Beverloo Law (i.e. Cb coefficient, with an error rate close to 2.9%) and an estimation of the Cohesive Index with Dmin parameter (minimum diameter for the powder to flow in the silo configuration);

- Since the Hall Flowmeter only makes one measurement for a small aperture size, it is not able to differentiate one sample from another (especially if they are very similar, cf. Virgin and Recycled versions of the same powder).

LEARN MORE ABOUT THE GRANUFLOW

References

Cascade of granular flows for characterizing segregation, G. Lumay, F. Boschin, R. Cloots, N. Vandewalle, Powder Technology 234, 32-36 (2013).

Combined effect of moisture and electrostatic charges on powder flow, A. Rescaglio, J. Schockmel, N. Vandewalle and G. Lumay, EPJ Web of Conferences 140, 13009 (2017).

Compaction dynamics of a magnetized powder, G. Lumay, S. Dorbolo and N. Vandewalle, Physical Review E 80, 041302 (2009).

Compaction of anisotropic granular materials: Experiments and simulations, G. Lumay and N. Vandewalle, Physical Review E 70, 051314 (2004).

Compaction Dynamics ofWet Granular Assemblies, J. E. Fiscina, G. Lumay, F. Ludewig and N. Vandewalle, Physical Review Letters 105, 048001 (2010).

Effect of an electric field on an intermittent granular flow, E. Mersch, G. Lumay, F. Boschini, and N. Vandewalle, Physical Review E 81, 041309 (2010).

Effect of relative air humidity on the flowability of lactose powders, G. Lumay, K. Traina, F. Boschini, V. Delaval, A. Rescaglio, R. Cloots and N. Vandewalle, Journal of Drug Delivery Science and Technology 35, 207-212 (2016).

Experimental Study of Granular Compaction Dynamics at Different Scales: Grain Mobility, Hexagonal Domains, and Packing Fraction, G. Lumay and N. Vandewalle, Physical Review Letters 95, 028002 (2005).

Flow abilities of powders and granular materials evidenced from dynamical tap density measurement, K. Traina, R. Cloots, S. Bontempi, G. Lumay, N. Vandewalle and F. Boschini, Powder Technology, 235, 842-852 (2013).

Flow of magnetized grains in a rotating drum, G. Lumay and N. Vandewalle, Physical Review E 82, 040301(R) (2010).

How tribo-electric charges modify powder flowability, A. Rescaglio, J. Schockmel, F. Francqui, N. Vandewalle, and G. Lumay, Annual Transactions of The Nordic Rheology Society 25, 17-21 (2016).

Influence of cohesives forces on the macroscopic properties of granular assemblies, G. Lumay, J. Fiscina, F. Ludewig and N. Vandewalle, AIP Conference Proceedings 1542, 995 (2013).

Linking compaction dynamics to the flow properties of powders, G. Lumay, N. Vandewalle, C. Bodson, L. Delattre and O. Gerasimov, Applied Physics Letters 89, 093505 (2006).

Linking flowability and granulometry of lactose powders, F. Boschini, V. Delaval, K. Traina, N. Vandewalle, and G. Lumay, International Journal of Pharmaceutics 494, 312–320 (2015).

Measuring the flowing properties of powders and grains, G. Lumay, F. Boschini, K. Traina, S. Bontempi, J.-C. Remy, R. Cloots, and N. Vandewall, Powder Technology 224, 19-27 (2012).

Motion of carbon nanotubes in a rotating drum: The dynamic angle of repose and a bed behavior diagram, S. L. Pirard, G. Lumay, N. Vandewalle, J-P. Pirard, Chemical Engineering Journal 146, 143-147 (2009).

Mullite coatings on ceramic substrates: Stabilisation of Al2O3–SiO2 suspensions for spray drying of composite granules suitable for reactive plasma spraying, A. Schrijnemakers, S. André, G. Lumay, N. Vandewalle, F. Boschini, R. Cloots and B. Vertruyen, Journal of the European Ceramic Society 29, 2169–2175 (2009).

Rheological behavior of β-Ti and NiTi powders produced by atomization

for SLM production of open porous orthopedic implants, G. Yablokova, M. Speirs, J. Van Humbeeck, J.-P. Kruth, J. Schrooten, R. Cloots, F. Boschini, G. Lumay, J. Luyten, Powder Technology 283, 199–209 (2015).

The influence of grain shape, friction and cohesion on granular compaction dynamics, N. Vandewalle, G. Lumay, O. Gerasimov and F. Ludewig, The European Physical Journal E (2007).