Ceramics

Are angle of repose and vertical flow related? (Using the GranuHeap and the GranuFlow)

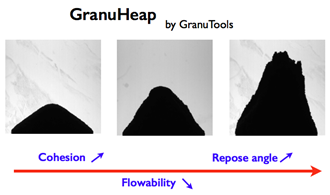

In general, the lower the repose angle is, the better the powder flowability is. The deviation between the real heap interface and the isosceles triangular heap provides the static cohesive index...

Theoretical Framework

Generalities

Granular materials and fine powders are widely used in industrial applications. To control and to optimize processing methods, these materials have to be precisely characterized. The characterization methods are related either to the properties of the grains (granulometry, morphology, chemical composition, …) and to the behaviour of the bulk powder (flowability, density, blend stability, electrostatic properties, …).

However, concerning the physical behaviour of bulk powder, most of the techniques used in R&D or quality control laboratories are based on old measurement techniques.

During the last decade, we have updated these techniques to meet the present requirements of R&D laboratories and production departments. In particular, the measurement processes have been automatized and rigorous initialization methods have been developed to obtain reproducible and interpretable results. Moreover, the use of image analysis techniques improves the measurements precision.

A range of measurement methods has been developed to cover all the needs of industries processing powders and granular materials. However, in this application note, we will be focused on the GranuHeap and GranuFlow instruments.

Introduction

The main goal of this application note is to give some indications to a customer interested by a GranuFlow and to define the best aperture in order to achieve a flow.

For this purpose, we decided to couple the heap shape analysis (Static Angle of Repose, measured by the GranuHeap) to the minimum aperture to achieve a flow in the GranuFlow.

However, it is important to note, that there is no direct link between those two measurements methods.

We just want to answer the following question: “If my powder achieves a Static Angle of Repose of 60°, will this product flow through the GranuFlow apertures?”

Material And Methods

Powders Selection

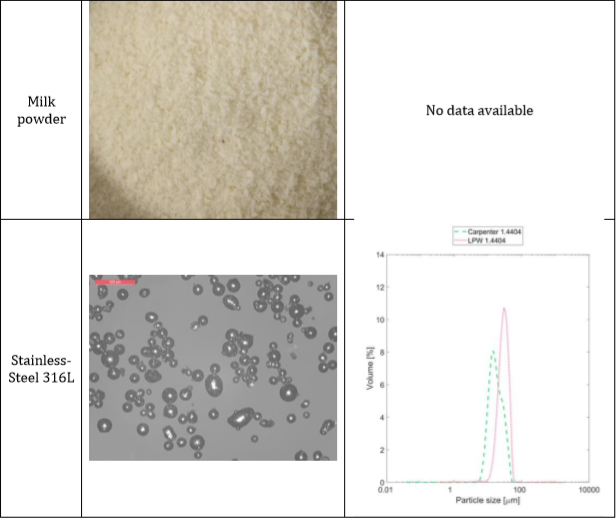

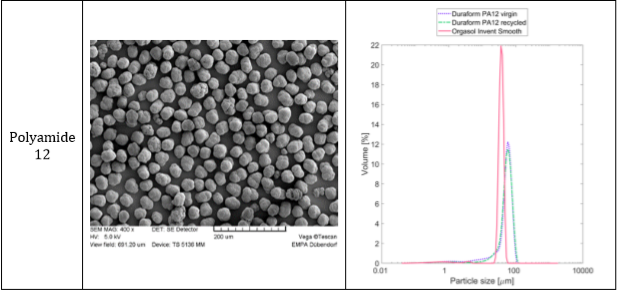

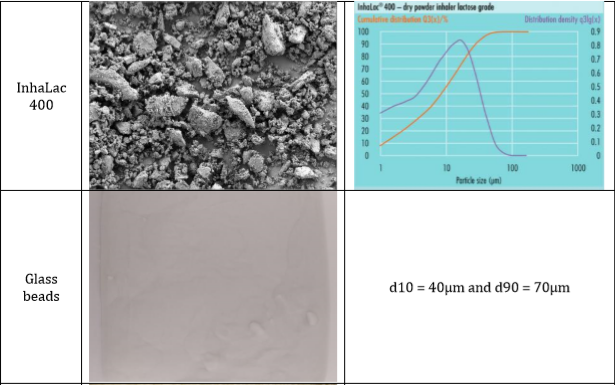

Five different samples were selected for this application note:

- InhaLac is a high quality crystalline lactose powder, designed for DPIs.

- One food product, a fat milk powder.

- A glass beads powders composed by spherical particles.

- One Stainless-Steel 316L products designed by LPW for Additive Manufacturing (Selective Laser Melting process).

- One Polyamide 12 powder designed by Arkema for Additive Manufacturing (Selective Laser Sintering process).

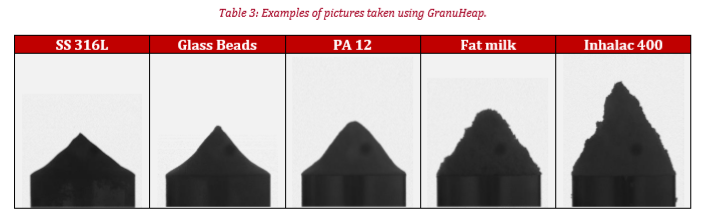

GranuHeap

When a powder is poured onto a surface, a heap is formed. It is well known that both the repose angle and the heap shape strongly depend on grain properties. In particular, a cohesive powder forms an irregular heap while a non-cohesive powder forms a regular conical heap. Therefore, a precise measurement of the heap shape provides useful information about the physical properties of the powder sample.

The GranuHeap instrument is an automated heap shape measurement method based on image processing and analysis. A powder heap is created on a cylindrical support. In order to obtain reproducible results, an initialization tube with an internal diameter equal to the circular support is installed on the support. After filling the initialization tube by hand with a fixed volume of powder (typically 100 ml), the tube goes up at the constant speed. Thereby, the powder is flowing from the tube to form a heap on the cylindrical support. A controlled rotation of the support allows obtaining different heap projections corresponding to different heap orientations. A custom image recognition algorithm determines the position of the powder/air interface. The repose angle refers to the angle of the isosceles triangle with the same surface than the powder heap projected image. This isosceles triangle corresponds to the ideal cohesiveness heap shape. The repose angle is computed for each image, i.e. for each heap orientation.

LEARN MORE ABOUT THE GRANUHEAP

In general, the lower the repose angle is, the better the powder flowability is.The deviation between the real heap interface and the isosceles triangular heap provides the static cohesive index. The static cohesive index is computed for each image, i.e. for each heap orientation.

Afterwards, an averaged value is computed. This static cohesive index is close to zero for a non-cohesive powder and increases when the cohesive forces inside the powder strengthen. The next Table summarizes the empirical relation between the results obtained with GranuHeap instrument and powder flowability.

LEARN MORE ABOUT THE GRANUHEAP

| Flow | Repose Angle (°) | Static Cohesive Index |

| Excellent | 25-30 | < 0.2 |

| Good | 31-35 | 0.3 - 0.5 |

| Fair | 36-40 | 0.6 - 0.8 |

| Passable | 41-45 | 0.9 - 1.2 |

| Poor | 46-55 | 1.3 - 1.7 |

| Very Poor | 56-65 | 1.8 - 2.4 |

| Very very poor | > 66 | > 2.5 |

For each experiment with the GranuHeap instrument, the 40mm diameter support was selected. 16 pictures were taken during the heap rotation (1 picture each 11.25°) to increase measurements accuracy. At the end of analysis, one final picture is taken to check the pile integrity when measurement is done. Only the average Angle of Repose (in °) and the standard deviation will be considered.

LEARN MORE ABOUT THE GRANUHEAP

GranuFlow

The GranuFlow instrument is a laboratory hopper associated with an electronic balance connected to a computer. The flow rate is measured as a function of the aperture sizes D to obtain a flow curve. The aperture size is modified easily with a rotating device.

LEARN MORE ABOUT THE GRANUFLOW

Finally, the flow curve is fitted with a theoretical model to extract the main parameters: the minimum aperture size Dmin and a the Beverloo parameter C related to the flowability of the sample.

The mass flowrate F through a circular orifice of diameter D is given by the product of the mean speed of the grains <Vout>, the aperture area and the bulk density ρ.

The Beverloo’s law is based on two hypotheses

- The flow is blocked when the orifice diameter is below a threshold Dmin.

- The grains experience a free fall before passing through the orifice. This relation comes from the idea that the jamming mechanism is due to the formation of a semi-spherical arch before the orifice. If this arch has a typical size proportional to the aperture, we obtainn ? = 0.5. To be more general, the parameter ? can be a free parameter.

In this application note, the GranuFlow was used to define the minimum diameter to obtain a flow.

Experimental Results

The following histogram represents the Static Angle of Repose (in °) on the left y-axis and the Minimum diameter (in mm) to achieve a flow using the GranuFlow for the five selected powders.

LEARN MORE ABOUT THE GRANUFLOW

However, the minimum tested diameter for this application note was 2mm:

LEARN MORE ABOUT THE GRANUHEAP

Those results allow us to see that only the Inhalac 400 wasn’t investigate with the GranuFlow, because no flow was observed using an aperture of 28mm. Nonetheless, for the Stainless-Steel 316L, glass bead, polyamide 12 and fat milk powders it was possible to observe a flow in the GranuFlow.

LEARN MORE ABOUT THE GRANUFLOW

Therefore, using a powder with a Static Angle of Repose of 58°, a flow is achieved with a 18mm aperture size, but a powder with a Static Angle of Repose of 68° no flow was observed. Consequently, if the measured powder Angle of Repose is below 58°, the GranuFlow can analyse this powder.

Conclusions

- This Application Note allow us to say that if your powder achieves a Static Angle of Repose lower than 58° in the GranuHeap, this powder can be analysed using the GranuFlow.

- Of course, it is obvious that Static Angle of Repose and flow through an aperture are not directly related. For instance, the SS316L powder and the glass beads sample achieve approximately the same Angle of Repose, but the SS316L powder mass flowrate is much higher in comparison with the glass beads.

- In other words, powder density will also play an important role in the vertical geometry. Basically, the more the powder density, the lower the minimum diameter to achieve a flow in the GranuFlow.

References

Cascade of granular flows for characterizing segregation, G. Lumay, F. Boschin, R. Cloots, N. Vandewalle, Powder Technology 234, 32-36 (2013).

Combined effect of moisture and electrostatic charges on powder flow, A. Rescaglio, J. Schockmel, N. Vandewale and G. Lumay, EPJ Web of Conferences 140, 13009 (2017).

Compaction dynamics of a magnetized powder, G. Lumay, S. Dorbolo and N. Vandewalle, Physical Review E 80, 041302 (2009).

Compaction of anisotropic granular materials: Experiments and simulations, G. Lumay and N. Vandewalle, Physical Review E 70, 051314 (2004).

Compaction Dynamics of Wet Granular Assemblies, J. E. Fiscina, G. Lumay, F. Ludewig and N. Vandewalle, Physical Review Letters 105, 048001 (2010).

Effect of an electric field on an intermittent granular flow, E. Mersch, G. Lumay, F. Boschini, and N. Vandewalle, Physical Review E 81, 041309 (2010).

Effect of relative air humidity on the flowability of lactose powders, G. Lumay, K. Traina, F. Boschini, V. Delaval, A. Rescaglio, R. Cloots and N. Vandewalle, Journal of Drug Delivery Science and Technology 35, 207-212 (2016).

Experimental Study of Granular Compaction Dynamics at Different Scales: Grain Mobility, Hexagonal Domains, and Packing Fraction, G. Lumay and N. Vandewalle, Physical Review Letters 95, 028002 (2005).

Flow abilities of powders and granular materials evidenced from dynamical tap density measurement, K. Traina, R. Cloots, S. Bontempi, G. Lumay, N. Vandewalle and F. Boschini, Powder Technology, 235, 842-852 (2013).

Flow of magnetized grains in a rotating drum, G. Lumay and N. Vandewalle, Physical Review E 82, 040301(R) (2010).

How tribo-electric charges modify powder flowability, A. Rescaglio, J. Schockmel, F. Francqui, N. Vandewalle, and G. Lumay, Annual Transactions of The Nordic Rheology Society 25, 17-21 (2016).