All resources

Spray-Drying Technique For Modifying Powder Rheology Analyzed With Granudrum Rheometer For Powder and Granuheap

To guarantee a high reproducibility of processes, a lot of applications need the use of free flowing powders. For plasma spraying deposition, for example, the substrate needs to receive a regular and constant flow mass of powder during all the projection duration...

Introduction

To guarantee a high reproducibility of processes, a lot of applications need the use of free flowing powders. For plasma spraying deposition, for example, the substrate needs to receive a regular and constant flow mass of powder during all the projection duration in order to ensure the regularity of the coating thickness during all the process.

In this short study, aqueous ceramic suspensions (blend of alumina and silica) are spray-dryed to produce dense granules of mixing alumina/silica particles [1]. The aim of this work is to produce a free flowing powder with a constant ratio Al2O3/SiO2 and good homogeneity suitable for reactive plasma spraying.

For checking the rheological properties of the powders before and after the spray-drying, the GranuDrum instrument is used for the grains characterizations [see references 1, 2 and 3 below].

Experimental procedure

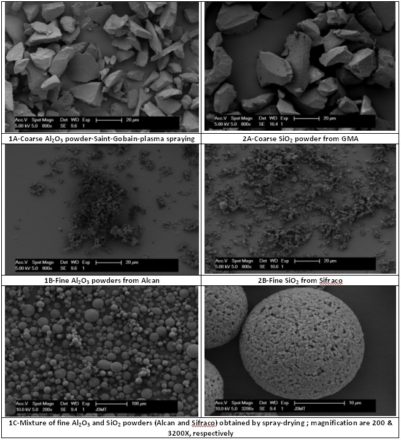

In this study, 3 blends of powders have been used (see figure 1):

A. The “coarse powders” blend composed from a mix of special powders for plasma torch. These powders are purchased from Saint-Gobain (Al2O3 – picture 1A) and GMA (SiO2– picture 2A). The particle size is around 20-40 µm.

B. The “fine powders” blend composed from a mix of micrometric alumina and silica (see picture 1B and 2B, respectively). These powders are purchased from Alcan and Sifraco. The particle size is around 1.5µm.

C. The ‘’Spray-dryed’’ blend prepared from suspension of fine powders[1] using Niro Mobile Minor to produce composite granules (see pictures 1C).

Rheological, static and dynamic properties of these three blends are characterized by using GranuDrum, GranuHeap and GranuPack instruments. We show in this application note the results obtained with GranuDrum instrument.

Figure 1: Electron micrographs of alumina/silica powders blends used in this study

LEARN MORE ABOUT THE GRANUDRUM

Results and Discussion

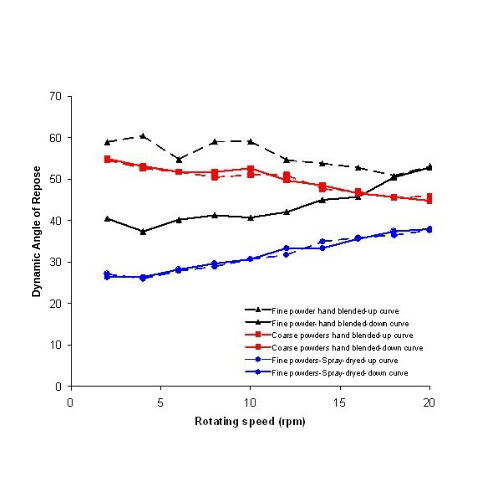

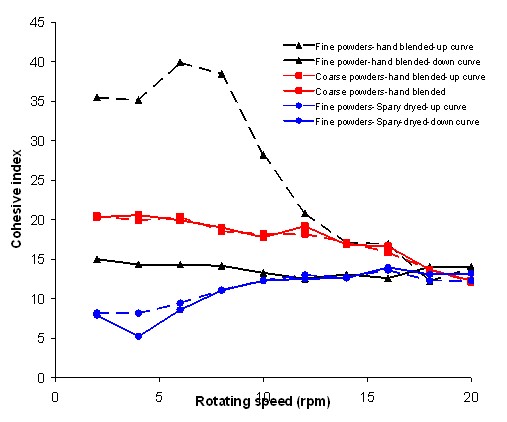

Figures 2 and 3 show the evolution of the flow angle and the cohesive index versus the rotating speed, respectively. Each measurement has been performed in a range about 2 and 20 rpm.

The controlled rotating speed is used to measure the flow curve with a two stages measuring cycle with a linear increase of rotating speed from 2 to 20 rpm (up curve) and a decrease to 2rpm rotating speed (down curve). The thixotropy of the blend is measured by the hysteresis area enclosed between the up- and down-curves .

Figure 2: Evolution of the flow angles versus rotating speed for 3 different blends of mullite

Figure 3: Evolution of the cohesive index versus the rotating speed for 3 different blends of powders

| GranuDrum Main Results | ||||||

|---|---|---|---|---|---|---|

| Rotating Speed | 2 rpm Up-Curve | 2 rpm Down-Curve | 6 rpm Up-Curve | |||

| Blend | Dynamic Angle of Repose (°) | Cohesive Index (°) | Dynamic Angle of Repose (°) | Cohesive Index (°) | Dynamic Angle of Repose (°) | Cohesive Index (°) |

| Fine Powders | 58.9 | 35.5 | 40.5 | 15 | 54.7 | 39.9 |

| Spray-Dryed | 27.1 | 8.2 | 26.4 | 7.9 | 27.8 | 9.4 |

| Coarse Powder | 54.6 | 20.5 | 54.9 | 20.3 | 51.7 | 20.4 |

Table 1: shows the main results obtained for each blend with the GranuDrum instrument

LEARN MORE ABOUT THE GRANUDRUM

The flow angle and cohesive index are given for two rotating speeds :

2 (go up and go down curves) and 6 rpm (go up)

We can observe on figure 2 that the “Spray-dryed” blend is characterized by the best flowability (lower flow angles).

The absence of thixotropy (no difference between the up and down blue curves) shows the robustness of the powder. The analysis of the curves show also a light shear thickening behaviour: as the rotating speed is increasing, as the flow angles increases. The “Spray-dryed” blend has the lowest cohesive index for low rotating speed (see blue curves on figure 3). Therefore, to limit the constraint for plasma spraying is the most interesting.

By comparison, we can see that the blend “coarse powders” (red curves on figure 2) is characterized by a higher flow curves and thus, a worth flowability than spray-dryed blend. For the blend “Fine powders ” (black curves), we can observe on figures 2 and 3 that this powder is characterized by a very large hysteresis (some differences between the go-up and go-down curves). The go-up curve on figure 3 clearly shows a large decrease of the cohesive index versus the rotating speed.

This behaviour is due to the modification of the intergranular interactions occurring during the measurement. Indeed, at low rotating speed, the individual particles build together because of, on one hand, the small sizes of the particles (1,5 µm particles) which increase the contact number and so the friction, and the other hand, large global interactions.

During the measurement (when the rotating speed is increasing), the particles form bigger grains/clusters (macroscopic balls from some few millimetres) what highly modifies the global cohesion. After theirs formations, these balls remain in the blend and alter strongly the flow angle (figure 2) and cohesive index values (figure 3).

See table 1 for their respective values at 2 rpm: This experiment gives important information.

First, we can see that we can highly modify the rheological behaviour of a blend by conditioning it (notably by rotating motion). This interesting property may be used for granulation process.

Secondly, balls formed during the measurement are preserved in the blend focusing the dependence of the history of the powder on the rheological properties.

In this case, the results shows the ‘’Fine powders’’ blend is not suitable for plasma spray technology because of its lack of flow ability and robustness.

Conclusion

The GranuDrum allows making a classification of the different samples considering their flowability and their cohesion under rotational motion. The best one is the “Spray-dryed” powder and the worst is the “Fine powders” blend. Moreover, the GranuDrum instrument shows some very important rheological differences between the samples.

So, ‘’Fine powder’’ blend is not suitable for plasma spraying because this powder is characterized by a high thixotropy (low robustness) and not good flow ability behaviour. The “Spray-dryed” powder is characterized by a higher flowability than commercial ‘’Coarse powders” blend which shows segregation problems due to large particles in the blend. Moreover, the ‘’Spray-dryed’’ blend has no thixotropy and, thus, is more predictable when the powder is motioned. This powder is so selected for making further plasma spraying tests.

References

[1] Mullite coatings on ceramic substrates: Stabilisation of Al2O3–SiO2 suspensions for spray drying of composite granules suitable for reactive plasma spraying, A. Schrijnemakers, S. André, G. Lumay, N. Vandewalle, F. Boschini, R. Cloots and B. Vertruyen, Journal of the European Ceramic Society 29, 2169–2175 (2009).

[2] Flow of magnetized grains in a rotating drum, G. Lumay and N. Vandewalle, Physical Review E 82, 040301(R) (2010).

[3] Flow ability and cohesion in metal powders