Additive manufacturing

Measuring metal powders flowability with Granutools instruments

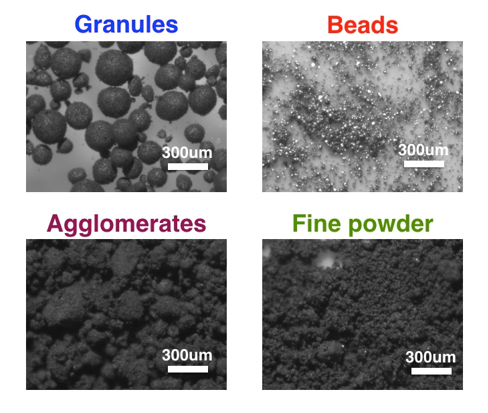

Four metal powders have been selected: granules obtained with a granulation process, small spherical polydisperse beads, a fine powder forming spontaneously agglomerates and a second fine powder.

Powders

Four metal powders have been selected: granules obtained with a granulation process, small spherical polydisperse beads, a fine powder forming spontaneously agglomerates and a second fine powder.

The next figure shows optical micrographs of these samples.

.png)

GranuDrum

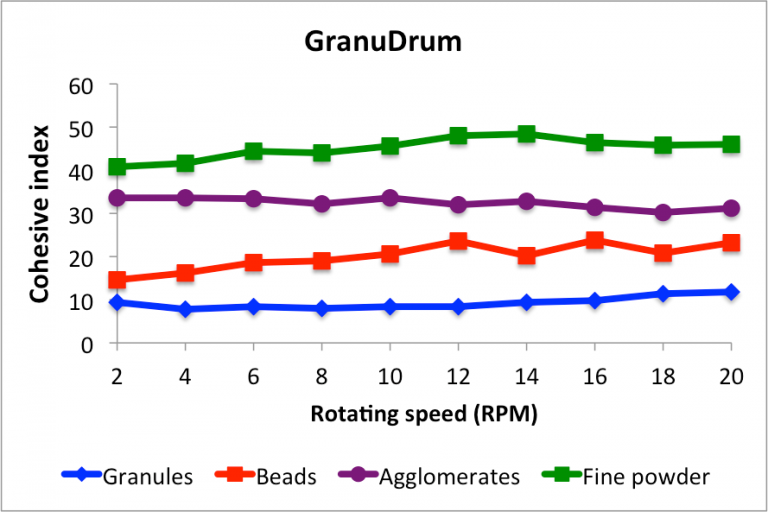

Then the next plots are showing the main GranuDrum parameters (flowing angle and cohesive index) as a function of the rotating speed.

LEARN MORE ABOUT THE GRANUDRUM

The next plot shows the evolution of the cohesive index as a function of the drum rotating speed.

The granules are almost non-cohesive because their size is typically higher than 100um. At the opposite, the fine powder is highly cohesive. In between, the powder forming agglomerates and the spherical beads are moderately cohesive.

The powder forming agglomerates show a shear thinning behavior because the flow increases the agglomerates size and then decrease the cohesiveness.

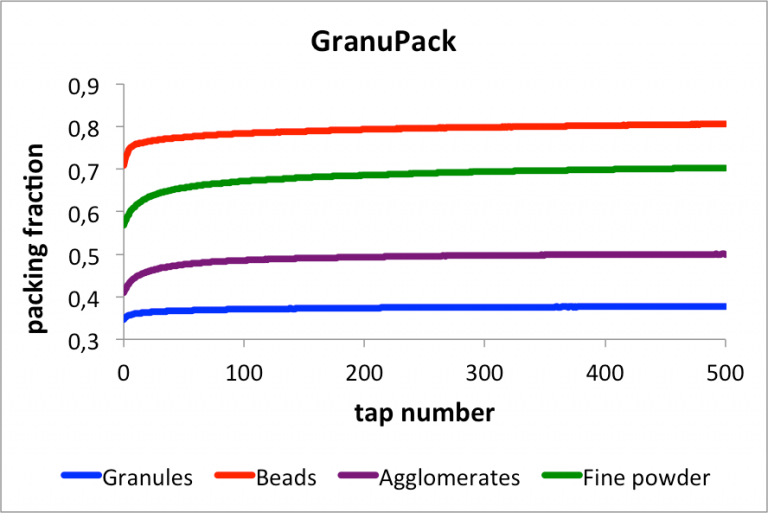

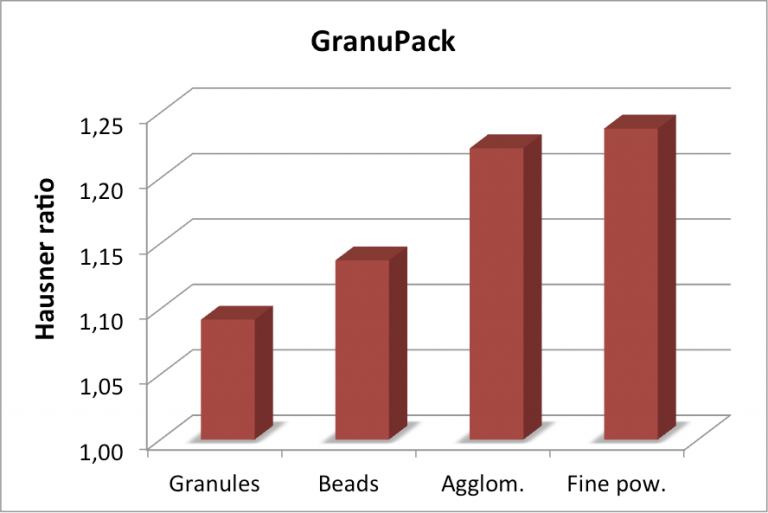

GranuPack

LEARN MORE ABOUT THE GRANUPACK

The low packing fraction obtained with the granules is related to the porosity of these granules. The spherical beads are leading to a high packing fraction due to theirs polydispersity.

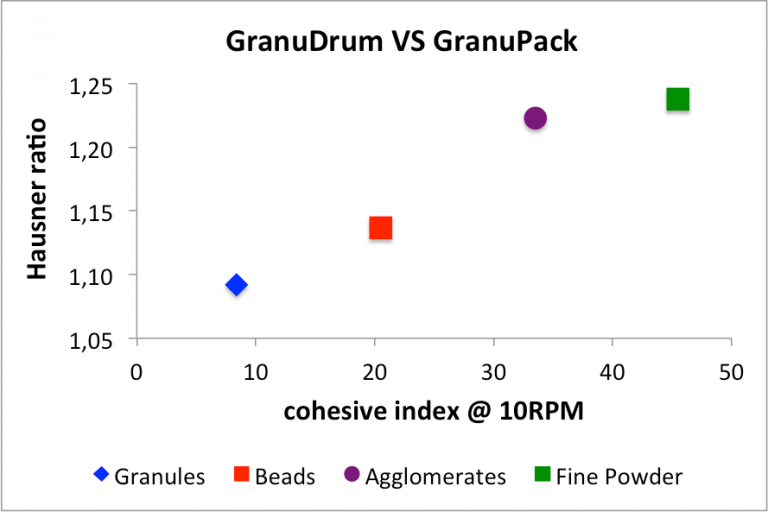

GranuPack Versus GranuDrum

The next plot shows the consistency between the results obtained with the GranuPack and the GranuDrum. The cohesive index is well correlated with the Hausner ratio.

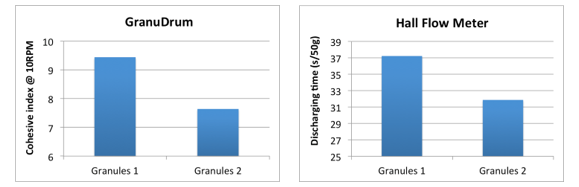

GranuDrum Versus Hall Flow Meter

Among the considered metal powders, only the granules are able to flow in the Hall Flow Meter (ASTM B213). The other metal powders are too cohesive.

Two types of granules have been measured with both Hall Flow Meter and the GranuDrum to show the consistency between these two methods. The powder having a higher cohesiveness (Granules 1) gives a higher discharging time. However, the GranuDrum allows extracting much more rheological information by varying the rotating speed and is user independent. Finally, the measurement cell is hermetically closed during a GranuDrum measurement improving the security.

LEARN MORE ABOUT THE GRANUDRUM