Food

Rice flowability characterization using GranuFlow

To make this study, three kind of rices have been selected: Gallo Risotti, Bosto Thai and Bosto Wok. For each kind of rice, we determine the major a and the minor b axis of the grain by using a classical office scanner and an image analysis software.

The Granuflow is an semi-automated instrument which allows to rapidly determine with a high accuracy, the flow of a powder through holes of different diameters. This instrument is able to give you in a few seconds, important information on the flow-ability of your material. The GranuFlow is equipped with a rotating plate pierced with 8 holes. You can chose between two plates with different hole diameters (small : 2 to 20 mm and large 24 to 36 mm holes).

LEARN MORE ABOUT THE GRANUFLOW

With the GranuFlow, you are able, by using the rotating plate, to easily find the minimum hole, in order to reach the flow of your powder. You can also determine the flow-ability of all your batches in order to control and to optimize your process or to simply compare your products during an innovation phase. Also thanks to the GranuFlow, you can make fast and large number of analysis with anon-destructive test.

So, you are able to control your product at every time, after production, during the storage before the delivery to guarantee your customers high quality products.

Influence of the grain shape on the flowability : rice

For making this study, three kind of rices have been selected: Gallo Risotti, Bosto Thai and Bosto Wok.

For each kind of rice, we determine the major a and the minor b axis of the grain by using a classical office scanner and an image analysis software. Elongation parameter (a/b) is then calculated from a and b axis.

Table 1 gives the main geometrical parameters of the different rices. Hole diameter used in this study is 18 mm.

| Rice | a (mm) | b (mm) | a/b |

|---|---|---|---|

| Gallo Risotti | 6.1 | 2.8 | 2.2 |

| Bosto Thai | 6.7 | 2.4 | 2.8 |

| Bosto Wok | 6.7 | 2.2 | 3 |

Table 1: Geometrical Parameters For Studied Rice

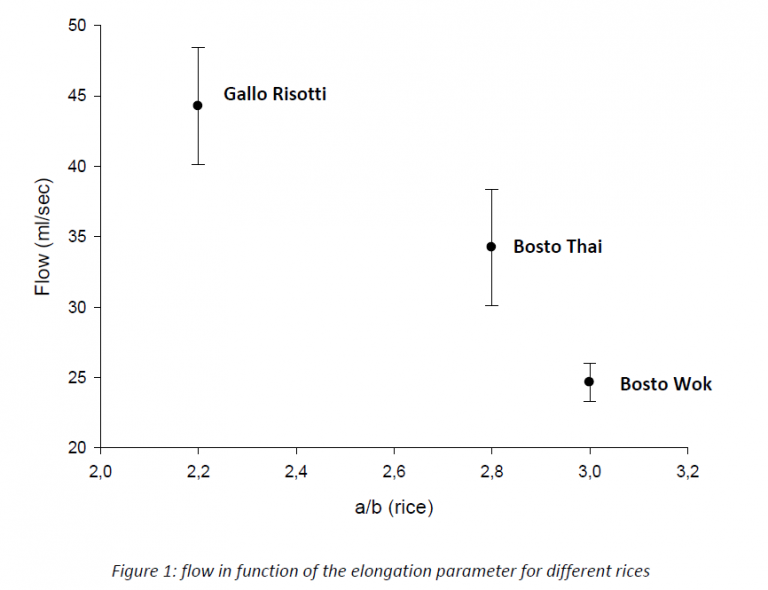

Figure 1 shows the evolution of the flow, in function of the elongation parameter for each rice. Standard deviation has been calculated based on 5 experiments. We can observe a strong correlation between the elongation parameter and the flow measured with the GranuFlow instrument. Flowability decreases with elongation parameter.

LEARN MORE ABOUT THE GRANUFLOW

So, Gallo Risotti with a the highest spherical shape (a/b = 2.2) is characterized by the best flowability.

The GranuFlow can be used to easily determine the flowability of the different rice and also to classify the different samples.

Figure 1: Flow in function of the elongation parameters for different rices

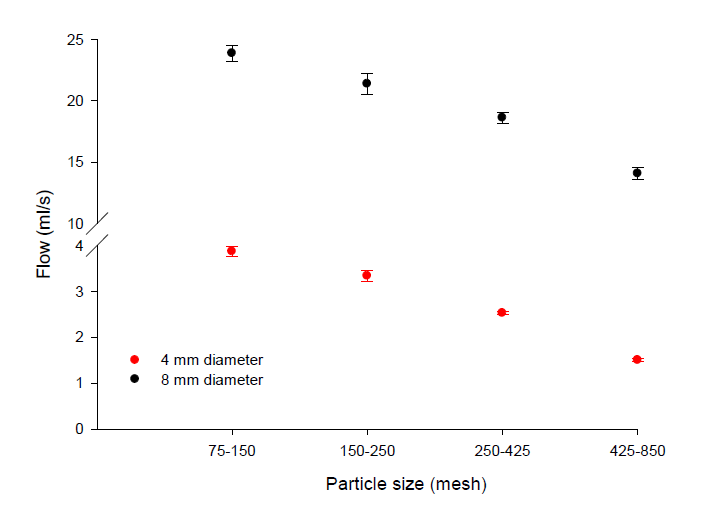

Influence of the grain size on the flowability: silica beads

In this study, 4 samples of silica beads have been used. Silica beads can be used in various applications and especially for polishing and abrasion. Table 2 shows the size of the particles of the analyzed beads.

LEARN MORE ABOUT THE GRANUFLOW

Samples have been analyzed with the GranuFlow at two different holes diameters : 4mm and 8mm.

| Range of Particle Size (µm) |

|---|

| 75-150 |

| 150-250 |

| 250-425 |

| 425-850 |

Table 2: Particle Size For Silica Beads

Figure 3: figure of the flow (m/s) vs particle size (mesh) : 4mm diameter and 8mm diameter

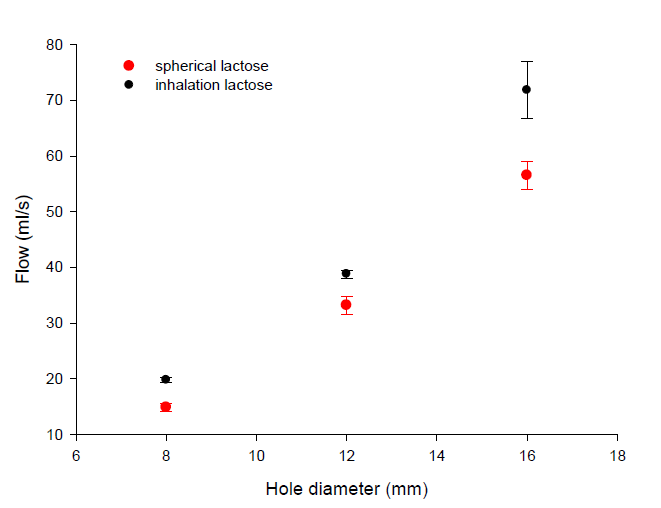

Figure 4: figure of the flow (m/s) vs particle size (mesh) : 4mm diameter and 8mm diameter spherical lactose and inhalation lactose

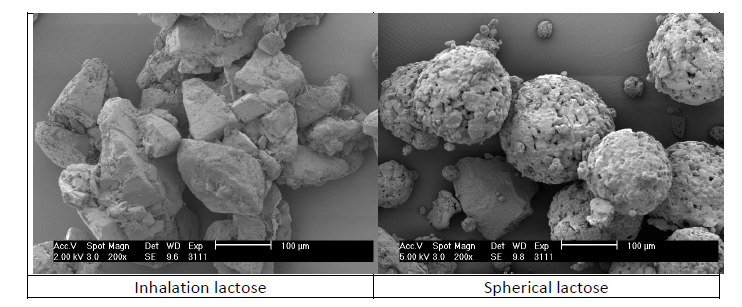

Figure 5: microscopical images of inhalation lactose and spherical lactose