Minerals

Electrostatic and flowing properties of limestone and lime powders using GranuDrum and GranuCharge

Limestone (Calcium carbonate) powders and the derivative products are extensively used in the construction industry, in chemical and metallurgical industries and also in agriculture.

Introduction

Limestone (Calcium carbonate) powders and the derivative products are extensively used in the construction industry, in chemical and metallurgical industries and also in agriculture. These powders are highly cohesive, and additives are commonly used to enhance their flowability. The additive and the quantity of additive have to be carefully chosen in order to optimize production processes. In this case, glycol-type additive was used.

In the present application note, we show how the GranuDrum instrument can be used to quantify the effect of flow enhancer additives.

LEARN MORE ABOUT THE GRANUDRUM

Moreover, the GranuCharge instrument is used to study the powder electrostatic properties of the powders.

Different limestone derivate products have been considered: Calcium carbonate CaCO3 (Limestone), Calcium hydroxide Ca(OH)2 (hydrated lime) and Calcium oxide CaO (quicklime). The main forces inducing cohesiveness in powders are van der Walls force (always present at the contact between two solids), capillary force (related to the water content), electrostatic force.

LEARN MORE ABOUT THE GRANUCHARGE

Therefore, the apparition of powder electrostatic charges inside it due to the triboelectric effect can increase powder cohesiveness.

In addition to the cohesiveness measurement performed by the GranuDrum, a GranuCharge powder electrostatic measurement allows to predict more precisely the behaviour of the powder inside the process line.

LEARN MORE ABOUT THE GRANUDRUM

Results and Discussion

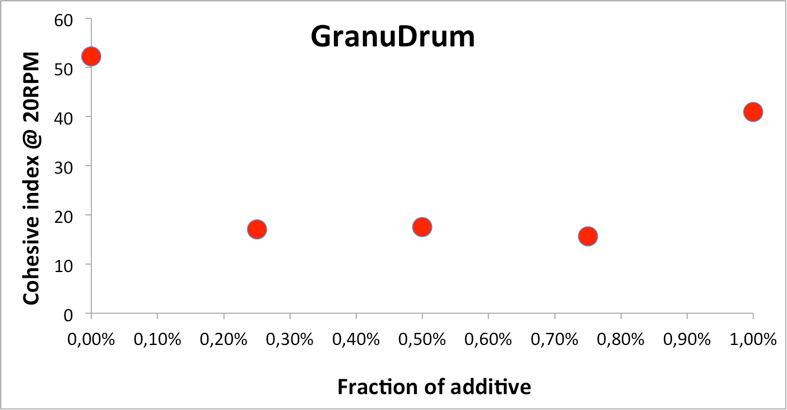

The next graph shows the evolution of the calcium oxide cohesive index as a function of the fraction of additive.

The cohesive index is measured with the GranuDrum at a rotating speed of 20RPM.

A strong decrease of the cohesiveness is observed after the addition of a small quantity of additive.

If more additive is added, the cohesiveness is stable before a significant increase of the cohesiveness. We will prove hereafter that this increase of cohesiveness is related to electrostatic charges.

LEARN MORE ABOUT THE GRANUDRUM

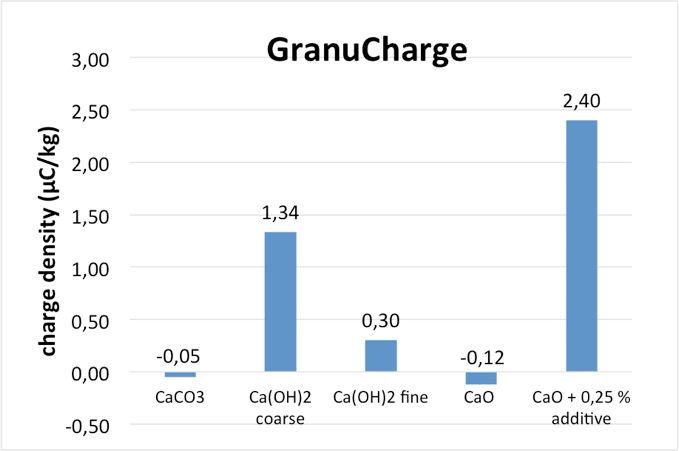

The charge density acquired by the powders during a flow in contact with stainless steel has been measured with the GranuCharge instrument. The next graph represents the charge density for the different products derived from limestone.

Significant differences are observed. Coarse (d>30um) and fine (d<20um) hydrated lime Ca(OH)2 powders do not acquire the same charge. In particular, the fine powder is less charged, certainly due to the existence of agglomerates.

With the coarse powder, the grains are moving more freely leading to a higher triboelectrification. Concerning the quicklime with or without additive, the difference is striking. The additive changes the charge sign and drastically increases the quantity of charge.

Therefore, while the additive globally decreases the cohesive forces between the grains, it specifically increases the electrostatic cohesive force. This observation certainly explains why the cohesiveness increases when the quantity of additive is too high.

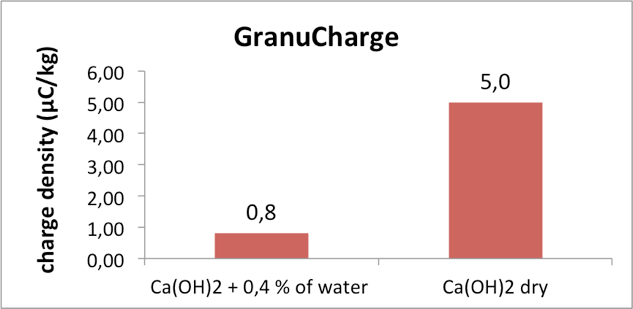

It is well known that small water content in powders decreases the electrostatic forces.

Indeed, the presence of water increases drastically the powder electrical conductivity, leading to a dissipation of the electrostatic charges.

This effect has been quantified with the GranuCharge instrument. The next graph show the charge density measured after a flow in contact with stainless steel (i) for a sample of hydrated lime with a water content of 0,4% and (ii) for the sample after a drying process.

The triboelectrification is multiplied by a factor 6 after the drying process.

LEARN MORE ABOUT THE GRANUCHARGE

Conclusion

The GranuDrum flowmeter is able to determine the optimal quantity of flow-enhancer additive for limestone and the derivative products.

Moreover, the analysis performed with the GranuCharge powder-triboelectrometer, allows understanding more precisely the mechanisms behind the cohesiveness.

In particular, when the quantity of additive is too high, the powder becomes sticky due to the apparition of electric charges.

Finally, the effect of the water content on the electrostatic charge has been demonstrated.

References

Measuring the flowing properties of powders and grains, G. Lumay, F. Boschini, K. Traina, S. Bontempi, J.-C. Remy, R. Cloots, and N. Vandewall, Powder Technology 224, 19-27 (2012).