Pharmaceutical

Tapped density characterization: comparison between the GranuPack and standardized methods

Tapped density measurement protocol has been standardized by modern pharmacopeias (USP, Ph. Eur, ISO, …). However, although used for decades, these protocols are based on old techniques inducing a lack of accuracy and repeatability.

[UPDATED ON 25 APRIL 2024]

Introduction

Generalities

Granular materials and fine powders are widely used in industrial applications. To control and to optimize processing methods, these materials must be precisely characterized. The characterization methods are related either to the properties of the grains (granulometry, morphology, chemical composition, …) and to the behaviour of the bulk powder (flowability, density, blend stability, electrostatic properties, …). However, concerning the physical behaviour of bulk powder, most of the techniques used in R&D or quality control laboratories are based on old measurement techniques. During the last decade, GranuTools updated these techniques to meet the present requirements of R&D laboratories and production departments. In particular, the measurement processes have been automatized and rigorous initialization methods have been developed to obtain reproducible and interpretable results. Moreover, the use of image analysis techniques improves the measurement precision. Many industries are already using GranuTools instruments range in different fields: additive manufacturing, food processing, pharmaceuticals, bulk material handling.

The tapped density is a very popular measure for powder characterization because of both the simplicity and the rapidity of the measurement. The ability of a powder sample to pack under taps gives a measure of the powder cohesiveness which can be linked to its flowability. Powders can thus be easily classified for quality control and process optimization.

LEARN MORE ABOUT THE GRANUPACK

Tapped density measurement protocol has been standardized by modern pharmacopeias and metallurgies (USP, Ph. Eur, ISO, ASTM, …). However, although used for decades, these protocols are based on old techniques inducing a lack of accuracy and repeatability. More accurate and repeatable characterization methods are now required to develop and/or improve powder grades and production processes. With this in mind, an improved tapped density measurement instrument has been developed by GranuTools based on the more recent fundamental research results (Lumay et al. 2004, Lumay et al. 2009, Fiscina et al. 2010, Traina et al. 2013). The GranuPack provides high accuracy and guarantees low operator dependency. The GranuPack is a modern and updated version of the standardized tapped density procedures.

The aim of this application note is to show how the results obtained with a standardized procedure can be compared to the GranuPack results. For this purpose, different standardized procedures from different industrial sectors (pharmaceutical and metal) will be investigated. Two grades of metallic powders and two grades of lactose powders will be tested by standardized procedures and classic GranuPack methods. The performance of the standardized method and the GranuPack method will be evaluated. Moreover, standardized procedure uncertainty sources will be highlighted.

GranuPack

GranuPack instrument (see fig. 1 left) is an automated and improved tapped density measurement method. The behaviour of the powder submitted to successive taps is analyzed with an automatized device. The Hausner ratio Hr, the initial density ρ(0) and the final density after n taps ρ(n) are measured precisely. Moreover, a dynamical parameter n1/2, defined as the number of taps required to reach half of the final compaction, can be extracted to characterize the packing dynamics.

LEARN MORE ABOUT THE GRANUPACK

The powder is placed in a metallic tube with a rigorous automated initialization process. Afterward, a light hollow cylinder is placed on the top of the powder bed to keep the powder/air interface flat during the compaction process. The tube containing the powder sample rose up to a fixed height of ΔZ and performs free falls. The free fall height is generally fixed to ΔZ = 1mm or ΔZ=3mm. The height h of the powder bed is measured automatically after each tap. From the height h, the volume V of the pile is computed. As the powder mass m is known, the density ρ is evaluated and plotted after each tap. The density is the ratio between the mass m and the powder bed volume V. With GranuPack method, the results are reproducible with a small quantity of powder (typically 35 ml). The Hausner ratio Hr is related to the compaction ratio and is calculated by the equation Hr = ρ(n) / ρ(0) , where ρ(0) is the initial bulk density and ρ(n) the tapped density computed obtained after n taps.

Furthermore, the ability to perform standardized measurements according to the more commonly used standards (ISO, USP, ASTM, …) has been given to the GranuPack. Special cells compliant with the requirements of the standards have been designed (see fig. 1 right). The protocols described in the standards are followed, and thus the inductive sensor is not used and the measurements are made visually by the operator. This new feature gives more versatility to the device allowing the operators to perform standards-compliant quality control as well as to benefit from the GranuPack improved protocol to conduct high-end development and process optimization. In the following, the GranuPack improved protocol will be referred to as “GranuPack Classic” and the standardized protocol as the chosen standard: USP616 or ASTM-B527.

LEARN MORE ABOUT THE GRANUPACK

Figure 1: Left: GranuPack instrument. Right: GranuPack configuration for standardized measurements

Powders Description

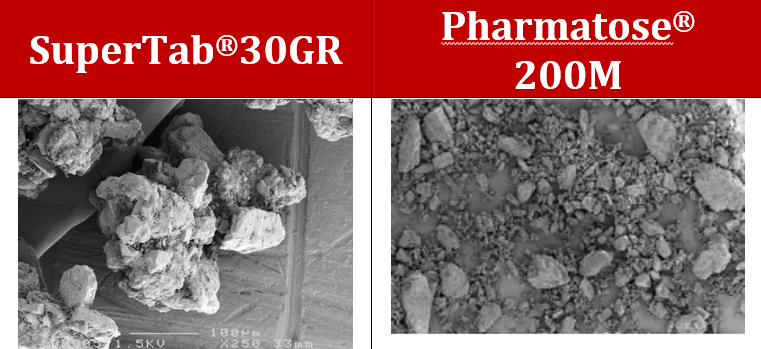

Two lactose powders (DFEPharma) have been selected for this study to compare the classic GranuPack method and the standardized procedure “USP616”:

- SuperTab®30GR: a granulated lactose

- Pharmotose®200M: a milled alpha lactose

Figure 2: SEM images of the powder’s particles allowing to describe the shapes of the grains

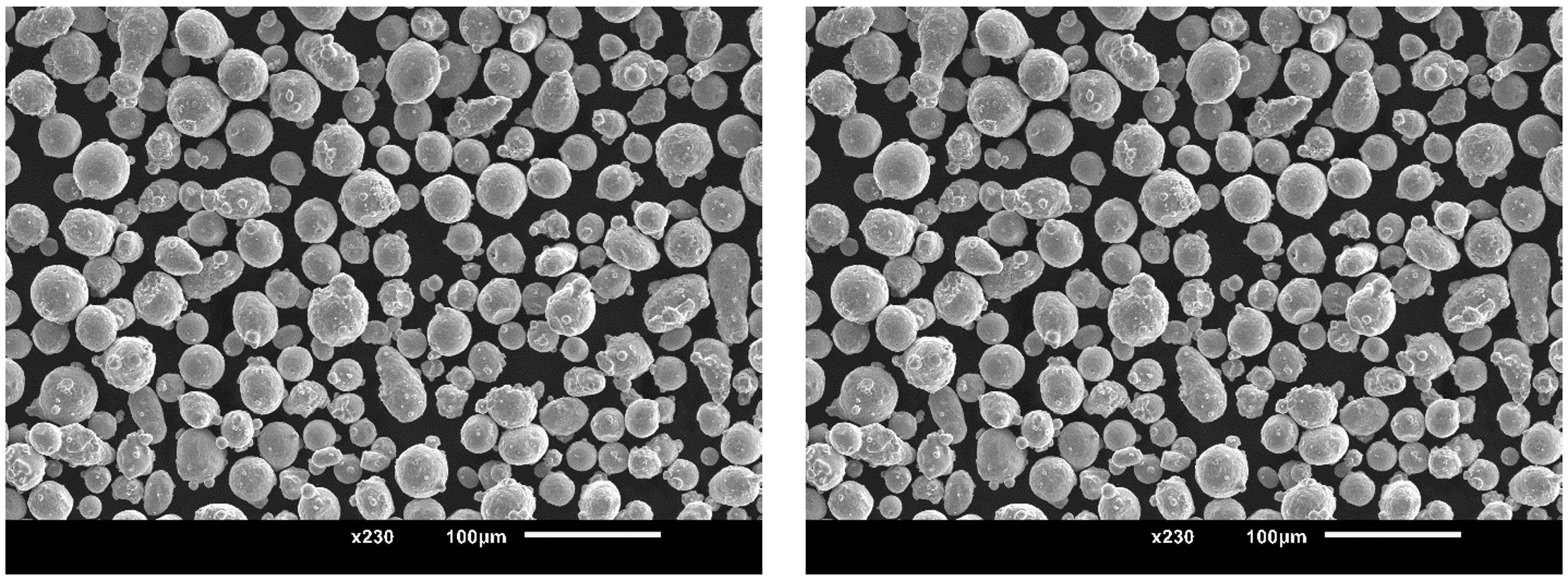

Two metal powders (Sandvik) have been selected for this study to compare the classic GranuPack method with the standardized procedure “ASTM-B527”:

- SS316L (90% < 22 µm): a fine gas atomized 316L stainless steel powder.

- SS316L (45-90 µm): a coarse gas atomized 316L stainless steel powder.

Figure 3: SEM micrographs of spherical 316L powder’s particles, produced by gas atomization.

The particle type and size distribution are summarized in Table 1:

| SuperTab® 30GR | Pharmatose® 200M | SS316L (< 22 µm)* | |

|---|---|---|---|

| Type | Granulated | Milled | Gas atomized |

| D10 (µm) | 38 | 4 | 4.0 |

| D50 (µm) | 126 | 38 | 10.5 |

| D90 (µm) | 297 | 111 | 22.0 |

Table 1: Type and size distribution of the particles composing the five powders.

*The sample SS316L (45-90 µm) is also gas atomized. The batch SS316L (45-90 µm) was sieved and exhibits a nominal range of 45 µm - 90 µm. The D10, D50 and D90 were not reported for this sample.

The SuperTab® grade is produced by fluid bed granulation and exhibits superior flowability. The Pharmatose® grade is a milled lactose with a smaller particle size than the SuperTab®30GR leading to a higher cohesiveness and lower flowability. Similarly, the sample SS316L (45-90 µm) is characterized by a lower cohesiveness and better flowability compared to sample SS316L (<22µm).

Standardized measurements

The standardized measurements suffer from several limitations:

Initial powder bed levelling:

After the pouring of the powder by the operator, the USP616 asks to “Carefully level the powder without compacting”. This powder levelling without compacting may be difficult to achieve and will induce variability in the apparent density measurement. Moreover, this procedure introduces an important dependence of the operator on the apparent density evaluation.

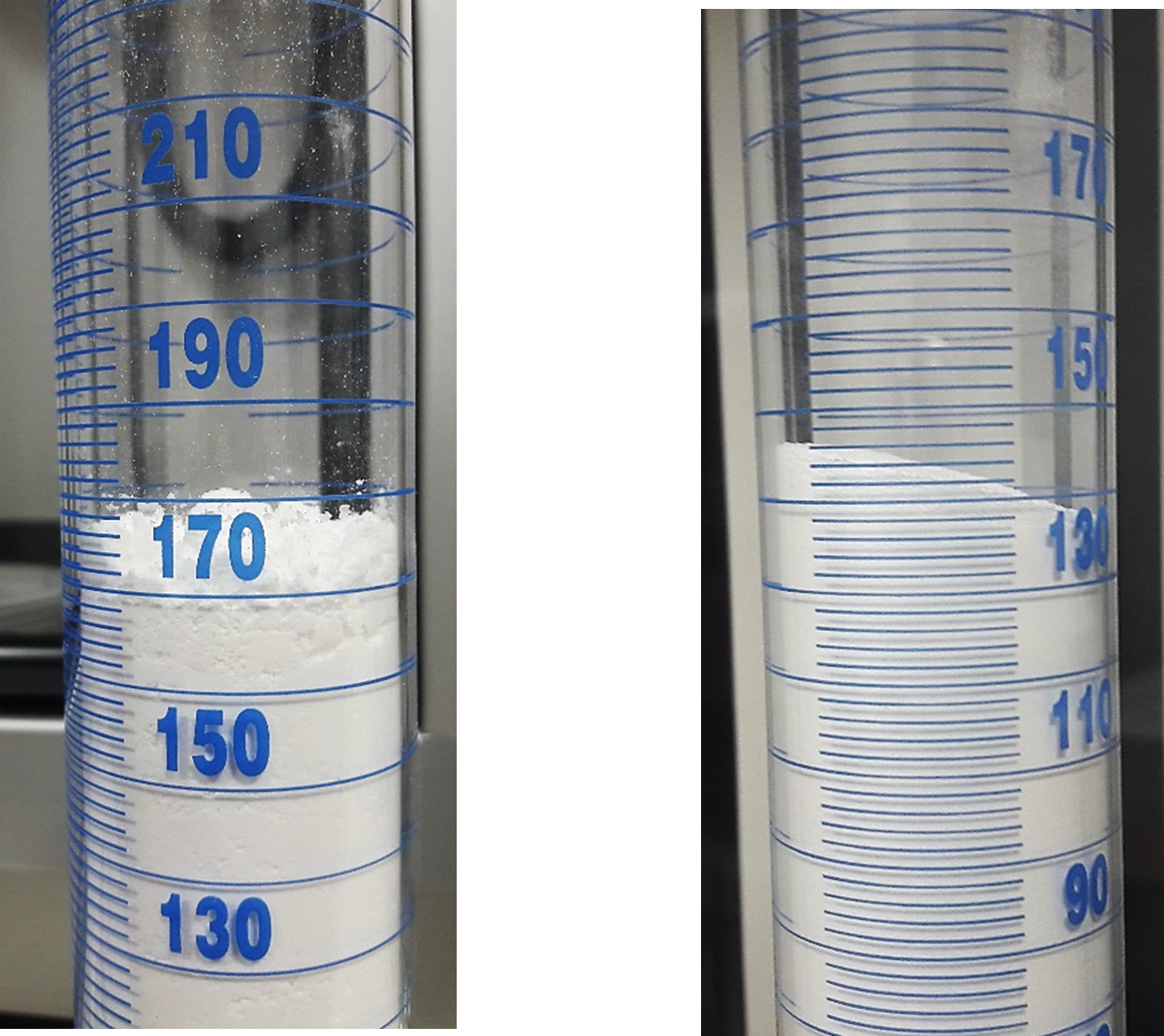

Visual assessment of the powder height:

Both standardized tapped density measurement (USP616 and ASTM B527) require visual evaluation of the powder height. Therefore, the measurement accuracy will depend on the graduated cylinder precision but also on the operator performing the volume reading. Indeed, for moderate to highly cohesive powders, the powder/air interface is very irregular (Figure 4 Left) and the operator has to determine an average interface position to estimate the volume of powder. Moreover, if the graduated cylinder is not perfectly levelled during taps, a slope can appear in the powder bed (Figure 4 Right). In this case, the measurement accuracy and operator dependency are even worst.

Figure 4: (Left) Irregular powder bed observed for cohesive powders. (Right) Slope of the powder/air interface due to not vertical displacement of the graduated cylinder.

Large amount of powder required:

The standardized measurement requires to use a large amount of powder (~100g). This is advantageous to decrease the relative error of the volume measurement. However, this amount of powder may not be available due to production or cost constraints, especially in the development process.

These limitations can now be overcome with the high accuracy and operator-independent measurement provided by the GranuPack Classic. In the following, we will show how results obtained with the standardized USP616 and ASTM B527 protocols can be compared with the GranuPack results.

1. USP616

Tapped density measurements according to the USP616 procedure is performed using a 250ml graduated cylinder readable to 2ml. Taps from a height of 3 ± 0.2mm performed at 250 ± 15 taps/min are applied to the powder. Measurements with taps from a height of 14mm are also possible according to the USP616 but will not be considered in this application note.

Before the measurement, approximately 100g of powder is poured inside the graduated cylinder. A first set of sequences of 10, 500 and 1250 taps is applied and then followed by subsequent 1250 taps sequences while the volume difference between two consecutive sequences is more than 2ml. After each taps sequence, a naked eye measurement of the volume is performed by the operator.

2. ASTM-B527

ASTM B527 is a standard test method for tap density (packed density) determination of metal powders and compounds. The tap density measurements according to the ASTM-B527 procedure is performed using a 100 ml graduated cylinder filled with 100 ± 0.5 g of powder. However, if the volume of 100 g of sample does not exceed 25 ml (or, if the powder’s apparent density exceeds 4 g/cm3), a graduated cylinder of 25 ml is preferred. In this report, we used a 25 ml graduated cylinder filled with 100 ± 0.5 g of 316L powder. The standard procedure specifies the taps from a height of 3 mm and a tapping frequency comprised between 100-300 taps/min (in this work, we used a tapping frequency of 250 ± 15 taps/min with a 3 mm tapping height).

Before the measurement, 100 ± 0.5 g of powder is poured inside a clean graduated cylinder. The cylinder is placed in the apparatus (in the GranuPack instrument). Then, the cylinder is tapped until no further decrease in the volume of the powder takes place. In this work, 3 sequences of 500 taps are applied to reach a total amount of 1500 taps and a volume difference between two consecutive sequences less than 1%. After each taps sequence, a naked eye measurement of the volume is performed by the operator. If the tapped surface is level, the volume is read directly. If the tapped surface is not level, the tap volume is determined by calculating the mean value between the highest and the lowest reading of the tapped surface. The final volume is read to the nearest 0.5 cm3 when using a 100 cm3 cylinder and to the nearest 0.2 cm3 when using a 25 cm3 cylinder. The standardized measurements suffer from the same limitations as described above (i.e. powder visual assessment which is user-dependent).

GranuPack Classic Analysis

Experimental Protocol

For a measurement with the GranuPack, only 35ml of powders are required. For the pharmatose powders, taps of 3mm height have been selected and a sequence of 3000 taps at a frequency of 1 tap/s is applied. For the 316L powders, taps of 3 mm height have been selected and a sequence of 1500 taps at a frequency of 1 tap/s is applied. Reproducibility has been assessed over three independent measurements with fresh powder.

In a classic GranuPack measurement, the following initialization protocol has been implemented to remove the operator dependency during the pouring of the powder in the measurement cell:

- An initialization tube (hollow cylinder) is placed inside the cell.

- The powder is poured inside the initialization tube by the operator.

- The initialization tube automatically moves upward at a constant speed.

This initialization protocol ensures that the powder is always poured the same way by removing operator dependency. To flatten the surface, a light diabolo is gently placed on top of the powder bed. This allows to overcome the bed levelling issues of the standardized method.

Once the initialization procedure is performed, the inductive sensor comes in the vicinity of the diabolo and the tap sequence starts. After each tap, the powder height is automatically measured by the sensor without intervention of the operator.

Experimental Results

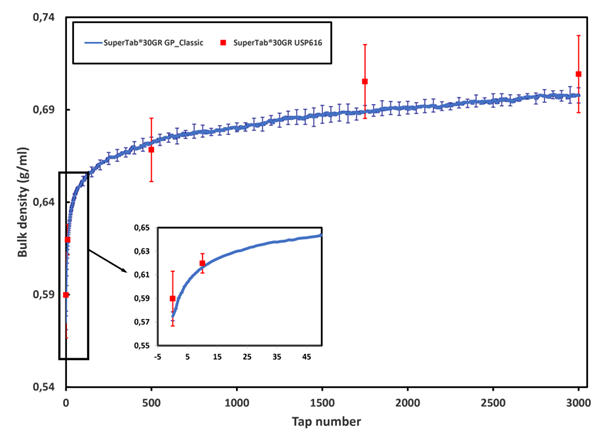

1. GranuPack classic – USP616

Figure 5 presents the bulk density evolution versus the number of taps obtained with the USP616 and the GranuPack Classic procedures for the SuperTab®30GR. A first advantage of the GranuPack Classic is clearly evidenced as it gives access to the whole packing curve. Therefore, the kinetics of packing can be investigated, which is not possible with the standardized method. At the opposite, the standardized method gives only four density measurements according to the USP616 procedure, and only allows to investigate apparent and tapped densities. The apparent and tapped densities obtained with the GranuPack Classic method are comprised in the variability of the standardized method, the differences can thus be considered as non-significant.

The error bars give an evaluation of the reproducibility of the measurements. The improvement given by the GranuPack Classic is clearly evidenced for both powders. Consequently, the higher accuracy of the powder height measurement with the sensor combined with the absence of operator dependency allows highlighting smaller differences in packing behaviour than the standardized procedure.

Figure 5: Density versus the tap number obtained with the GranuPack Classic and the USP616 procedure for SuperTab®30GR. Error bars are ± the standard deviation on the three independent tests.

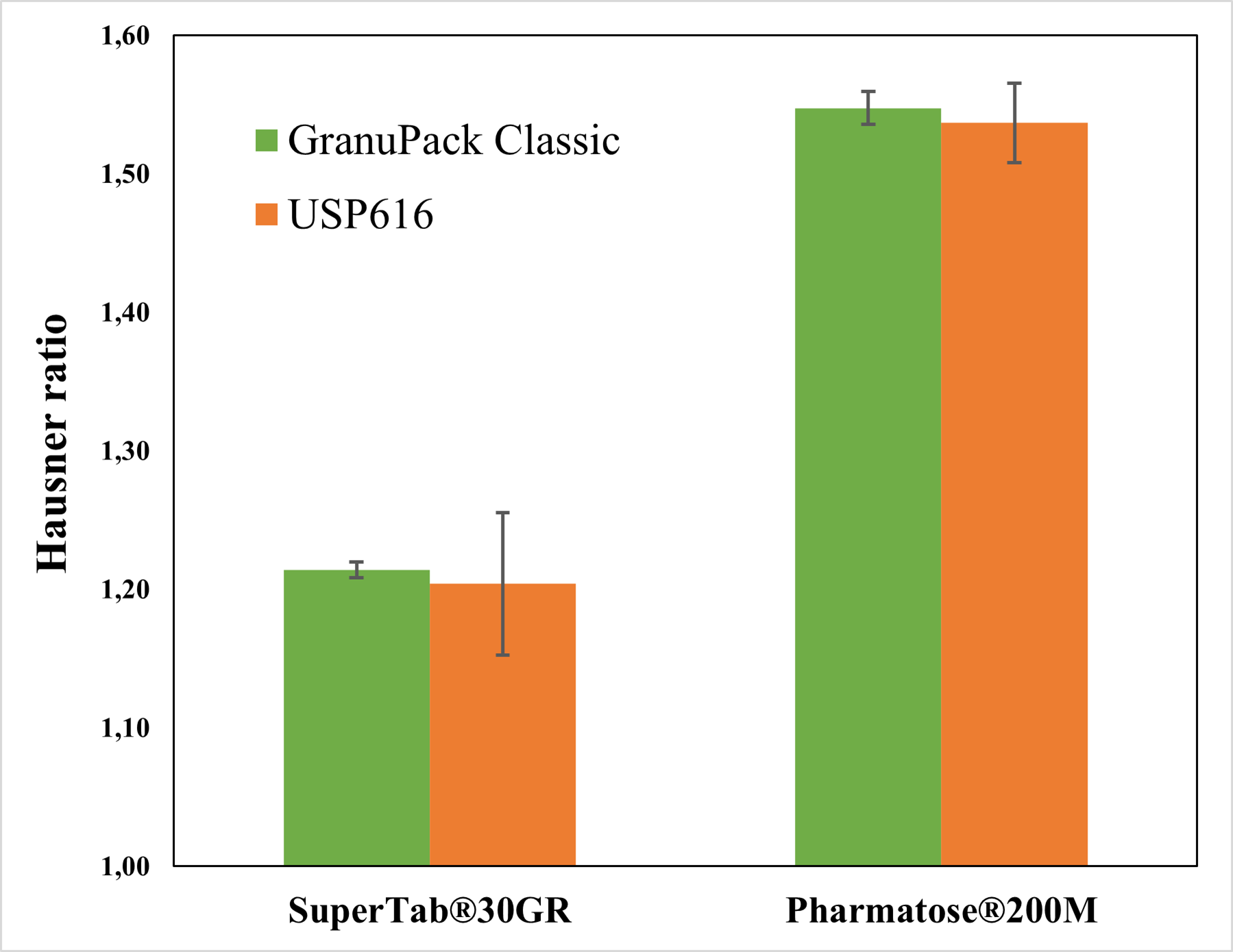

The Hausner ratios computed as the ratio of the apparent and tapped densities after 3000 taps are presented in Figure 6. Again, the higher reproducibility of the GranuPack Classic method is clearly evidenced. Therefore, by removing the user dependency with the improved initialization protocol the GranuPack Classic procedure helps to drastically improve the measurement reproducibility.

Interestingly, both methods give a very similar Hausner ratio, only slightly lower with the USP616 procedure. However, it can be noted to these small differences can be considered non-significant regarding the variability of the standardized procedure. Moreover, this indicates that powder characterization results obtained with the GranuPack Classic can be directly compared to older ones performed with the standardized procedure.

LEARN MORE ABOUT THE GRANUPACK

Figure 6: Hausner ratio measured with the GranuPack Classic and the USP616 procedure for both powders. Error bars are ± the standard deviation on the three independent tests.

2. GranuPack classic – ASTM B527

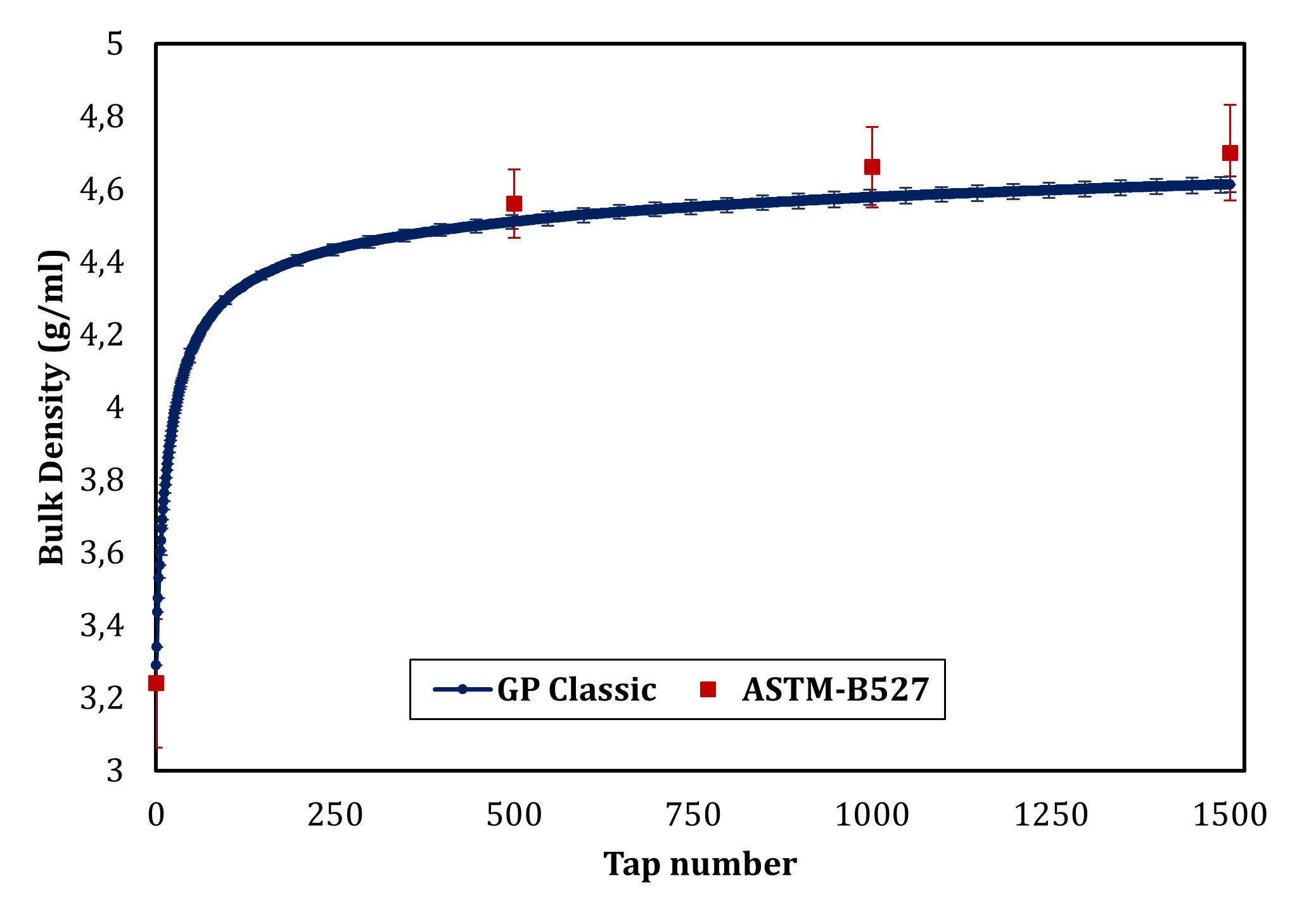

Figure 7 presents the evolution of the bulk density with the number of taps obtained with the standardized ASTM B527 and the GranuPack Classic procedures for the sample SS316L (<22µm). As introduced above, one advantage of the GranuPack is the access to the whole packing curve. Therefore, the kinetics of packing can be investigated, which is not possible with the standardized method. At the opposite, the standardized method gives only four density measurements, and only allows to investigate apparent and tapped densities. The apparent and tapped densities obtained with the GranuPack Classic method are comprised in the variability of the standardized method, the differences can thus be considered as non-significant.

Figure 7: Bulk density versus tap number measured with the GranuPack Classic and the ASTM-B527 procedures for the sample SS316L (<22 µm). Error bars are standard deviations around the mean computed over three independent tests.

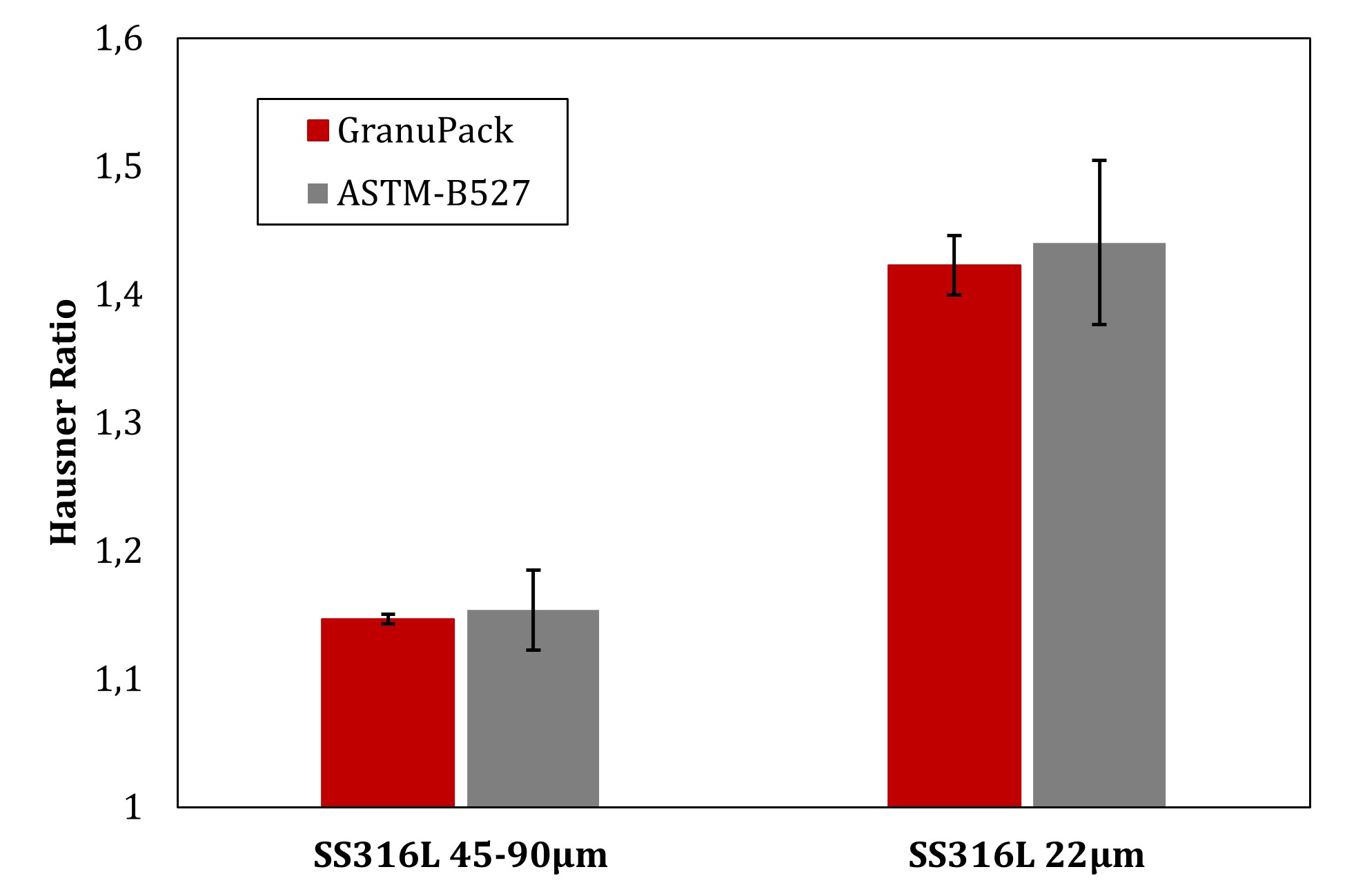

The Hausner ratios computed as the ratio of the apparent and tapped densities after 1500 taps are presented in Figure 8. The improved reproducibility of the GranuPack Classic method is clearly evidenced. The GranuPack Classic procedure helps to drastically improve the measurement reproducibility by removing the user dependency with the improved initialization protocol and by measuring precisely the powder height with an inductive sensor coupled to the diabolo.

Interestingly, both methods give a very similar Hausner ratio, only slightly lower with the GranuPack classic procedure. However, these small differences can be considered non-significant regarding the variability of the standardized procedure. Moreover, this indicates that powder characterization results obtained with the GranuPack Classic can be directly compared to previous results obtained with a standardized procedure.

Figure 8: Hausner ratio measured with the GranuPack Classic and the standardized ASTM B527 procedures on both metal powders. Error bars are standard deviations around the mean computed over three independent tests.

Conclusions

In this application note, standardized tapped density measurement methods (USP616 and ASTM B527) were compared with the GranuPack method. Both methods give a very similar Hausner ratio, with non-significant differences regarding the variability of the standardized methods. Results obtained with the improved GranuPack method can thus be easily compared with the ones obtained with the standardized procedures.

LEARN MORE ABOUT THE GRANUPACK

Main sources of variability of the standard procedures have been highlighted and are overcome with the GranuPack Classic method thanks to its automated initialization protocol and operator-independent powder height measurement. This has been demonstrated by the much lower variability obtained with the GranuPack Classic measurements.

Main advantages of the GranuPack Classic method over the standardized one can be summarized as:

- Automated and high reproducible initialization protocol.

- Operator-independent and highly accurate powder height measurements after each tap.

- Access to the whole packing curve to investigate the packing kinematics.

LEARN MORE ABOUT THE GRANUPACK

Bibliography

Cascade of granular flows for characterizing segregation, G. Lumay, F. Boschin, R. Cloots, N. Vandewalle, Powder Technology 234, 32-36 (2013).

Combined effect of moisture and electrostatic charges on powder flow, A. Rescaglio, J. Schockmel, N. Vandewalle and G. Lumay, EPJ Web of Conferences 140, 13009 (2017).

Compaction dynamics of a magnetized powder, G. Lumay, S. Dorbolo and N. Vandewalle, Physical Review E 80, 041302 (2009).

Compaction of anisotropic granular materials: Experiments and simulations, G. Lumay and N. Vandewalle, Physical Review E 70, 051314 (2004).

Compaction Dynamics of Wet Granular Assemblies, J. E. Fiscina, G. Lumay, F. Ludewig and N. Vandewalle, Physical Review Letters 105, 048001 (2010).

Effect of an electric field on an intermittent granular flow, E. Mersch, G. Lumay, F. Boschini, and N. Vandewalle, Physical Review E 81, 041309 (2010).

Effect of relative air humidity on the flowability of lactose powders, G. Lumay, K. Traina, F. Boschini, V. Delaval, A. Rescaglio, R. Cloots and N. Vandewalle, Journal of Drug Delivery Science and Technology 35, 207-212 (2016).

Experimental Study of Granular Compaction Dynamics at Different Scales: Grain Mobility, Hexagonal Domains, and Packing Fraction, G. Lumay and N. Vandewalle, Physical Review Letters 95, 028002 (2005).

Flow abilities of powders and granular materials evidenced from dynamical tap density measurement, K. Traina, R. Cloots, S. Bontempi, G. Lumay, N. Vandewalle and F. Boschini, Powder Technology, 235, 842-852 (2013).

Flow of magnetized grains in a rotating drum, G. Lumay and N. Vandewalle, Physical Review E 82, 040301(R) (2010).

How tribo-electric charges modify powder flowability, A. Rescaglio, J. Schockmel, F. Francqui, N. Vandewalle, and G. Lumay, Annual Transactions of The Nordic Rheology Society 25, 17-21 (2016).

Influence of cohesives forces on the macroscopic properties of granular assemblies, G. Lumay, J. Fiscina, F. Ludewig and N. Vandewalle, AIP Conference Proceedings 1542, 995 (2013).

Linking compaction dynamics to the flow properties of powders, G. Lumay, N. Vandewalle, C. Bodson, L. Delattre and O. Gerasimov, Applied Physics Letters 89, 093505 (2006).

Linking flowability and granulometry of lactose powders, F. Boschini, V. Delaval, K. Traina, N. Vandewalle, and G. Lumay, International Journal of Pharmaceutics 494, 312–320 (2015).

Measuring the flowing properties of powders and grains, G. Lumay, F. Boschini, K. Traina, S. Bontempi, J.-C. Remy, R. Cloots, and N. Vandewalle, Powder Technology 224, 19-27 (2012).

Motion of carbon nanotubes in a rotating drum: The dynamic angle of repose and a bed behavior diagram, S. L. Pirard, G. Lumay, N. Vandewalle, J-P. Pirard, Chemical Engineering Journal 146, 143-147 (2009).

Mullite coatings on ceramic substrates: Stabilisation of Al2O3–SiO2 suspensions for spray drying of composite granules suitable for reactive plasma spraying, A. Schrijnemakers, S. André, G. Lumay, N. Vandewalle, F. Boschini, R. Cloots and B. Vertruyen, Journal of the European Ceramic Society 29, 2169–2175 (2009).

Rheological behavior of β-Ti and NiTi powders produced by atomization for SLM production of open porous orthopedic implants, G. Yablokova, M. Speirs, J. Van Humbeeck, J.-P. Kruth, J. Schrooten, R. Cloots, F. Boschini, G. Lumay, J. Luyten, Powder Technology 283, 199–209 (2015).

The flow rate of granular materials through an orifice, C. Mankoc, A. Janda, R. Arévalo, J. M. Pastor, I. Zuriguel, A. Garcimartín and D. Maza, Granular Matter 9, p407–414 (2007).

The influence of grain shape, friction and cohesion on granular compaction dynamics, N. Vandewalle, G. Lumay, O. Gerasimov and F. Ludewig, The European Physical Journal E (2007).