Blog

Improvement Of the Angle Of Repose Powder Tester

This article explains why GranuHeap instrument is a real technological breakthrough in the measurement of the angle of repose to meet the requirements of modern industries.

Improvement Of the Angle Of Repose Powder Tester

An important part of the powder testers used in industries are based on old measurement principles. Too often, the devices are designed to be operated manually and the measurements are performed by naked eyes. This results in an important influence of the operator on the measurement. Therefore, the measure is inaccurate and non-repeatable. These manual powder testers do not longer meet the requirements of modern industries manufacturing complex products.

DISCOVER OUR APPLICATION NOTES

At GranuTools, on the one hand, we develop original powder testing methods and on the other hand, we improve existing methods. The improvement of existing methods is based on automatization of the measurement and on the use of sensors and cameras for the acquisition. Moreover, a sample preparation method and a finely controlled initialization procedure are systematically applied. Consequently, the influence of the operator is suppressed. Finally, GranuTools powder testers are controlled by a computer and the CFR 21 Part 11 compliant software helps for data analysis and storage.

Here, we focus on the repose angle. This macroscopic parameter depends on the friction between the grains and on the cohesive forces. A high repose angle corresponds to high friction and/or cohesiveness and therefore to poor flowability. The repose angle is a straightforward and easy-to-measure parameter to compare powders. Unfortunately, the value of this angle depends on the experimental parameters and on the process used to create the heap. Hence, it is important to keep the parameters constant and to use a well-controlled initialization process. In addition, the usability of the instrument is a must because it is often necessary to repeat the measurement to obtain good data.

GranuHeap instrument is a fully automated and computer-controlled version of the repose angle powder tester satisfying all the conditions presented above. An initialization procedure based on the use of an initialization tube rising slowly upward allows to create a heap without any intervention of the operator. Afterward, the heap shape is analyzed with a camera and a dedicated image treatment procedure, without any user-dependency. On top of that, the heap is rotating to analyze the heap shape from all perspectives. The data are collected, analyzed, and stored by an intuitive software.

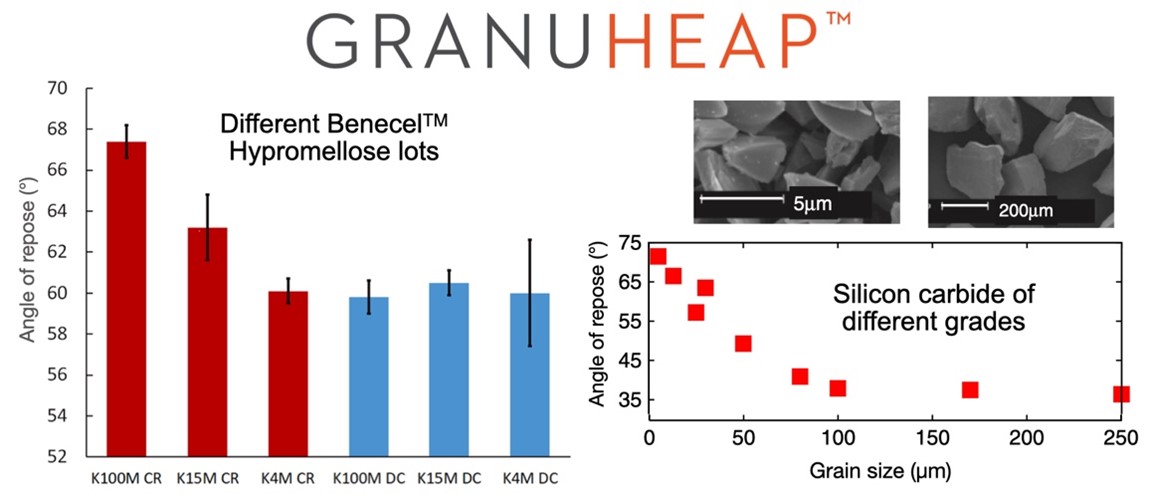

GranuHeap instrument has shown many times its ability to differentiate quickly and easily a set of powders by classifying them according to their flowability. In the next figure, two examples are shown. The first one concerns a set of powders used in pharmaceutical direct compression processes [1] and the second one deals with abrasives of different grades [2]. In both cases GranuHeap was able gives efficiently a first classification of the powders before going ahead in the project. A third example concerning powders used in tableting process can be found in this publication [3].

LEARN MORE ABOUT THE GRANUHEAP

When a deeper understanding of the powder rheology is required, a dynamic measurement is needed to complement the angle of repose measurement. The dynamic measurement complementing naturally the angle of repose is the dynamical angle of repose (or flowing angle) measured with the GranuDrum. Moreover, the GranuDrum allows quantifying the powder cohesiveness. This approach is also explained in the publications [1-3].

LEARN MORE ABOUT THE GRANUDRUM

Following the same principle of improvement of old powder testers, the GranuPack is an automated version of the well-known tapped density measurement. The GranuPack is fully automatic with an initialization procedure and a dedicated software. Moreover, the GranuPack has a series of optional functionalities like a high-temperature cell or cells and measurement procedure following the main norms (ISO8967, ISO3953, ASTM B527, USP 616, ChP 2020, and EP 2.9.34). But that’s another story.

LEARN MORE ABOUT THE GRANUPACK

[1] Loss-In-Weight Feeding, Powder Flow And Electrostatic Evaluation For Direct Compression

- Allenspach, P. Timmins, G. Lumay, J. Holman, T.Minko, International Journal of Pharmaceutics Volume 596, 1 March 2021, 120259

[2] Measuring the flowing properties of powders and grains - 2012

- Lumay, F. Boschini, K. Traina, S. Bontempi, J.-C. Remy, R. Cloots, and N. Vandewalle, Powder Technology 224, 19-27, 2012

[3] Flowability of Lactose Powders to Optimise Tableting Processes - 2020

- Neveu, P. Janssen; G. Lumay, ONdrugDelivery Magazine, Issue 109 (July 2020), pp 58–62