Blog

Improving solid-state battery production by combining Granutools measurements and DEM simulations

In this study, we suggest the digital twins approach coupled with Granutools instruments to improve procesess in the real production line.

DEM use for solid-state battery production

The production of batteries is intensified with the growing need for energy storage for new technologies such as electric cars. At the same time, the performance of the batteries needs to be constantly enhanced, requiring an improvement of the processes in the production line. New processes emerge and handle directly the raw material in powder form to get rid of the use of solvents for electrode forming. However, handling powder is challenging and much attention is paid to powder handling optimization in manufacturing processes for solid-state batteries and dry-processes.

DEM simulation gained in popularity for solid-state battery production. Indeed, the complexity of powders coupled with the complexity of the manufacturing processes leads to big difficulties in solving problems with a mathematical model or an experimental approach. On the contrary, DEM simulation allows to investigation of the influence of many parameters, varying the process geometry as well as the powder material used. Consequently, DEM simulation would be the privileged tool for process improvement in solid-state battery production.

Why use Granutools instruments?

If the principle seems simple, reproducing the powder flow numerically requires fixing correctly the grain parameters, such as particle roughness, shape, coefficient of friction, cohesion,… to reflect reality. In addition, these parameters are generally unknown and challenging to measure. For this reason, the digital twins approach is more and more preconized. It consists of adjusting by trial and error these parameters until the digital twin flow corresponds to the real flow observed for the powder. In such an approach, an experimental setup with a simple geometry easy to numerically implement as a digital twin must be used. In this way, the simulated flow can be easily analyzed and compared to the real experimental setup.

Granutools instruments are ideal tools for calibration with the digital twins approach. Indeed, they are designed with simple geometries that are easy to implement in a numerical simulation and provide metrics easy to compute and to interpret. In addition, some metrics are more sensitive to specific parameters, allowing an efficient calibration of each parameter with a dedicated metric.

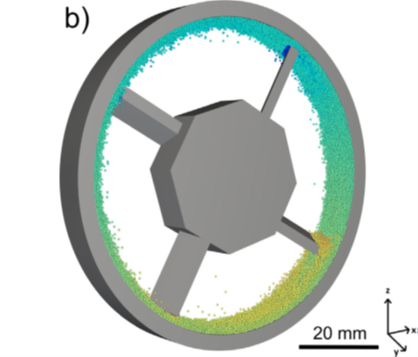

For instance, dry-mixing is an important step that is poorly understood while the performance of the battery highly depends on this first stage. DEM simulation calibrated with a digital twin of the GranuDrum allows to better understand the mechanisms occurring during the dry mixing and to improve this process in the real production line. Many other processes such as fibrillation in a twin screw extruder or powder compaction into the calendar depend on granular physics phenomena and grain parameters (particle shape, friction, cohesion, size distribution,…). All these processes handling powder and granular materials for electrode production benefit from a better understanding and improvements thanks to well-calibrated DEM simulations.

DEM simulation of a dry-mixing process calibrated with a GranuDrum

(Figure from: F. Frankenberg et al., Powder Technology, February 2024.)

Conclusion

The growing field of electrode production research requires intensive use of DEM simulation, especially for the upcoming technologies such as dry-processes and solid-state batteries, handling materials in powder form. Indeed, the large number of parameters to investigate and the complexity of the involved processes justify the need for DEM simulations. Nevertheless, the physical parameters of these simulations need to be correctly calibrated to reproduce real powder behaviours.

The digital twins approach coupled with the Granutools instrument is a powerful method for calibrating in a reasonable time DEM simulations playing with a large number of parameters (Paper). Indeed, the Granutools instruments are based on simple geometries, easy to implement numerically as digital twins. In addition, each metric provided by the instruments is more sensitive to a specific parameter in the powder, allowing to calibrate efficiently each parameter in the DEM simulation with the adequate tool.

If you are interested in this topic don’t hesitate to keep in touch with us!

.png)