Blog

GranuFlow: the improved gravity-driven characterization tool

This blog article focuses on the GranuFlow instrument, a gravity-driven powder flow tester that offers precise, accurate and reproducible measurements.

Gravity-driven flow

Gravity-driven measurements have been used for decades to characterize powder flow. They generally consist of letting a powder contained in a small tank flow through an aperture at the bottom of the tank. This simple experiment is easy to reproduce and mimics at a lower scale the flow during silo discharge. Therefore, instruments were developed to perform this kind of powder flow characterization method. Most of them are tools created a long time ago, using simple technologies such as a stopwatch to measure the time to empty the tank of powder. Some only propose a unique aperture size to test the powder. This limits the characterization of the powder especially since it is known that the flow rate depends on the aperture size, as described by the Berverloo model. In addition, some powders have a minimal aperture below which the flow is blocked due to arching effects that cannot be measured by so restricted methods.

Why use GranuFlow?

GranuFlow is a gravity-driven powder flow tester, compliant with industry standards such as "Flow Through an Orifice" (USP 1174, EP 2.9.36), and much more. Indeed, GranuFlow brings advantages that overcome the limitations encountered with old methods. Thanks to a scale connected to a computer and controlled with user-friendly software, the data acquisition of the mass flow versus time is done automatically, allowing an accurate and reproducible measure of the flow rate, with traceability of the acquired data. The silo containing the powder is designed with a simple geometry, limiting the possible effect of the angle of a funnel-like shape and facilitating a possible digital twin implementation. In addition, the GranuFlow offers different aperture sizes. The operator can easily switch from one aperture size to another to evaluate the flow rate evolution with the aperture size.

Differentiation of the powders from their flow curve

From the measurements, important parameters of the powder can be obtained. Indeed, the flow index C and the minimal aperture size obtained thanks to the Beverloo law adjustment provide a complete characterization of the flow rate evolution with the aperture size. The curve of the flow rate evolution is a signature of a powder, allowing powder differentiation.

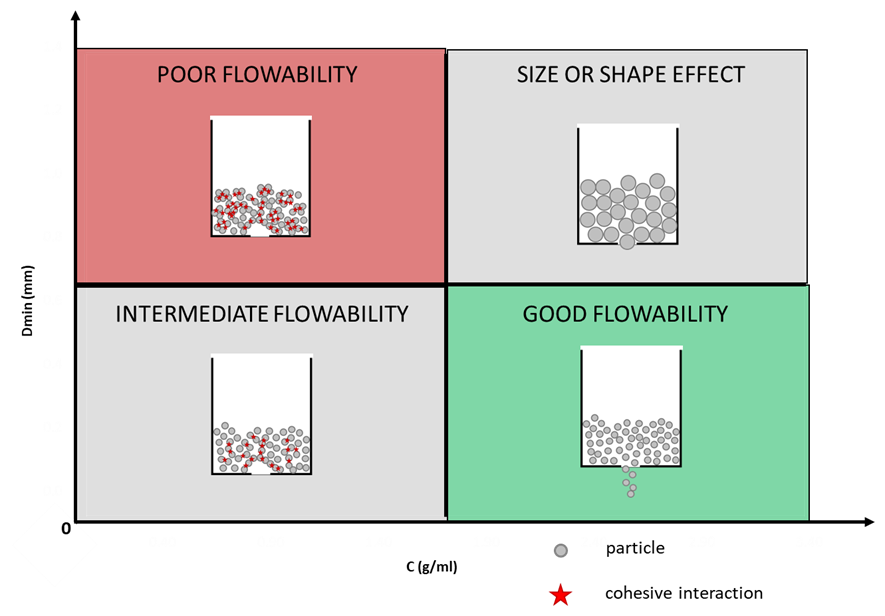

By analyzing the C and , the powder flowability can be estimated and compared to other powders, as presented in the Figure below. Both parameters depend on friction, particle size, shape, and cohesion but evolve differently with these characteristics. Since C increases with flowability while decreases, typical regions of ‘’good’’, ‘’poor’’ or ‘’intermediate’’ flowability can be defined. According to a couple of parameters (C, ), the flowability of a powder can be quantified depending on its region in the Figure.

Sketch of the flowability classification provided by the GranuFlow measurement

Conclusion

Contrary to a basic silo discharge experiment, the GranuFlow goes further than standards "Flow Through an Orifice" (USP 1174, EP 2.9.36), and offers a more complete description of the flow rate of a powder. The simple and easy-to-use experiment performed is highly improved by the user-friendly software that automates and secures the data acquisition and provides indexes characterizing the powder and quantifying its flowability. This characterization is based on a physical approach, using the Beverloo model, that helps for a better understanding of the fundamental mechanisms controlling the powder flow. Therefore, the GranuFlow is an adequate tool for powder flowability qualification for industrial use as well as an interesting tool for fundamental research.