Blog

How to evaluate powder granulation with the GranuDrum

Discover how the GranuDrum can help assess the impact of granulation on powder flowability with this blog article.

Context

During the flow of powders, fine particles tend to agglomerate due to the presence of cohesive forces, creating larger particles. This leads to a shift of the particle size distribution which subsequently modifies the flowing behavior. Granulation can be done on purpose or can be a consequence of the flow through the process line. In both cases, quantifying the propensity of the powder to granulate is interesting to adjust formulations or to predict the change in flowability and/or rheology during the processing. Granutools propose a simple protocol to quantify the effect of granulation on the flowability in the GranuDrum.

Protocol

The investigation of granulation can follow a specific protocol using the GranuDrum.

This process involves characterizing the flow properties of fresh and granulated materials, ensuring consistency through pre-conditioning, and performing measurements with the GranuDrum. For the full protocol, please contact us.

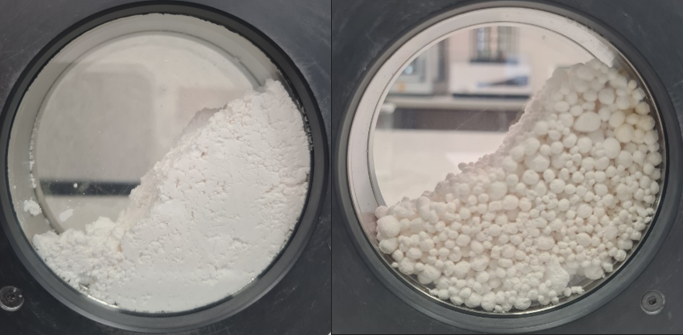

Figure 1: Left: non granulated sample. Right: sample after external granulation

LEARN MORE ABOUT THE GRANUDRUM

Data Interpretation

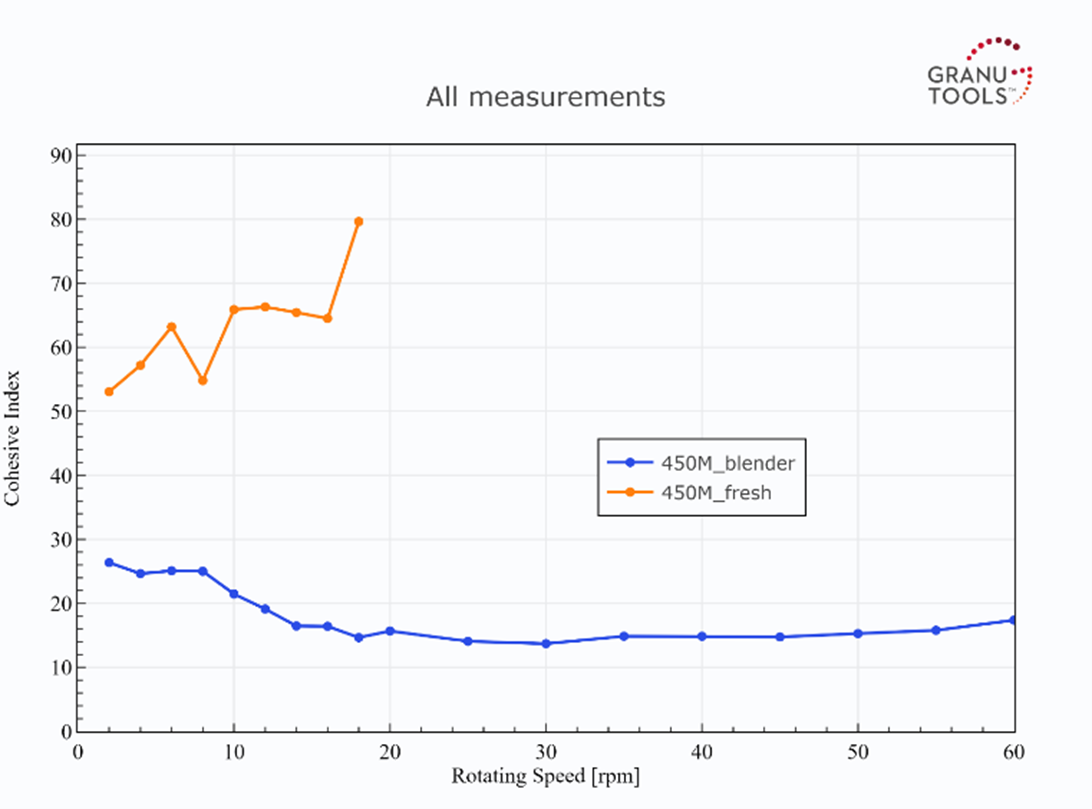

Figure 2 presents the Cohesive Index versus rotating speeds curves for the non-granulated and the granulated powders. In this example, the fresh powder has been measured only up to 18 rpm due to heavy stickiness. The influence of powder granulation is clearly highlighted: the creation of the large agglomerates significantly decreases the Cohesive Index, leading to a major improvement of the flowability.

Figure 2: Cohesive Index versus Rotating Speed curves obtained for the fresh and granulated samples

Conclusion

The protocol allows to evaluate powder granulation behavior with the GranuDrum. This protocol can be applied to any kind of granulation method, and also to evaluate the granulation level at different stage of a processing line.