Additive manufacturing

Measuring additive manufacturing powder flowability with Granutools instruments: Case study

The high sensitivity of GranuPack instrument is exploited to measure the influence of oxidation on Aluminum powder behavior...

Influence of oxidation on Aluminum powder

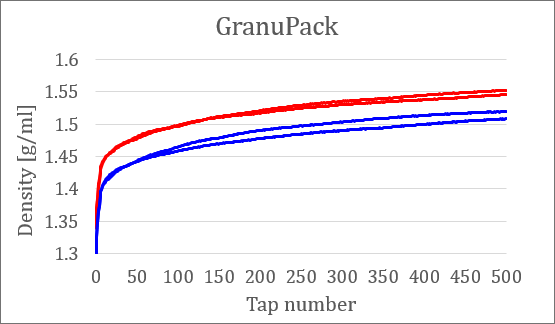

The high sensitivity of GranuPack instrument is exploited to measure the influence of oxidation on Aluminum powder behavior. The next plot shows the compaction curve of a reference Aluminum powder and the compaction curve obtained with the same powder containing oxidation.

To check the reproducibility, each measurement has been repeated.

| p(0) | p(500) | Hausner | p(∞) | |

|---|---|---|---|---|

| Al Meas.1 | 1.339 | 1.546 | 1.154 | 1.614 |

| Al Meas.2 | 1.351 | 1.553 | 1.15 | 1.63 |

| Al with oxidation Meas.1 | 1.298 | 1.508 | 1.162 | 1.578 |

| Al with oxidation Meas.2 | 1.297 | 1.52 | 1.171 | 1.597 |

The oxidation is found to decrease slightly the density and to increase the Hausner ratio.

Therefore, the oxidation decreases the flowability. This effect is certainly due to a modification of the grain surface (roughness). The differences are weak but perfectly measurable with the GranuPack instrument.

LEARN MORE ABOUT THE GRANUPACK

Influence of grain size and shape on powder flow

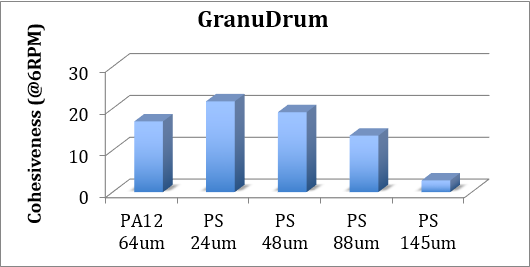

A classical polyamide powder (PA12 2200) is compared with polystyrene powders. PA12 grains are angular and PS grains are almost perfect spheres.

The next plot shows the clear link between the average grain size and cohesiveness. When the average grain size decreases, the influence of cohesive forces (Van der Waals, electrostatic and capillary forces) increases and the powder flow becomes intermittent.

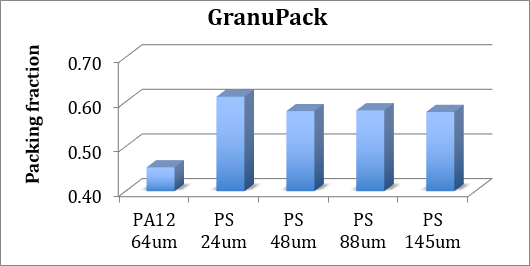

The information about flowing properties given by GranuDrum can be completed with information about the density given by GranuPack. In particular, a precise and reproducible measurement of the packing fraction is easy to perform.

LEARN MORE ABOUT THE GRANUDRUM

The next plot evidences the clear influence of grain shape on the packing fraction. The PA12 grains are angular, leading to a lower packing fraction and therefore to a higher porosity.

Influence of an additive (flow aid agent)

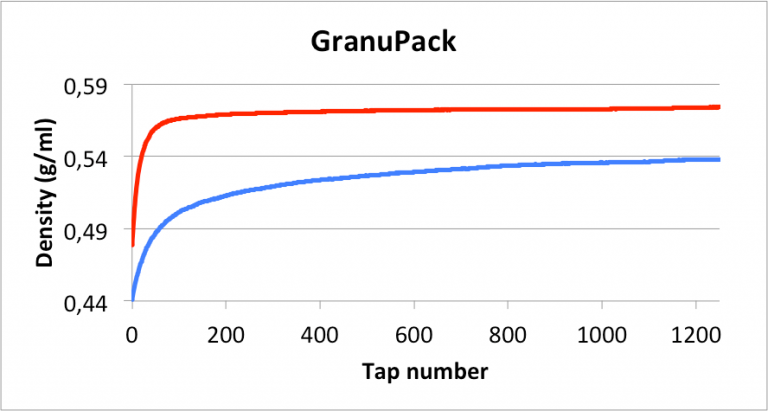

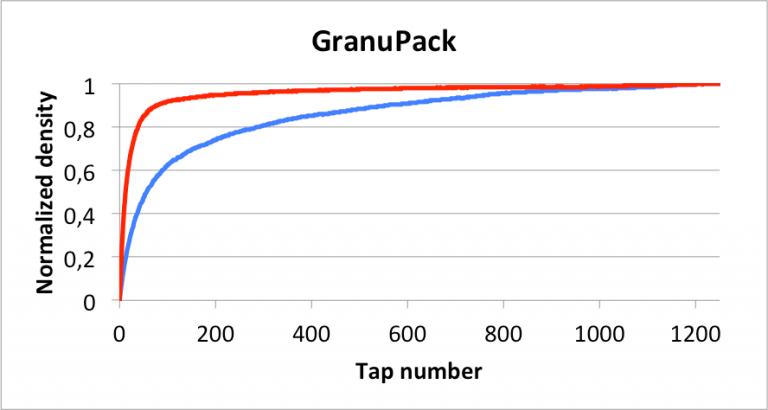

A typical powder used in additive manufacturing has been analysed with the GranuPack instrument (blue curve in the next plot). A small quantity of flow aid agent has been added and the GranuPack measurement has been repeated (red curve in the next plot).

The flow aid agent increases the density. Moreover, a normalization of the compaction curves (see next plot) shows that the compaction dynamics is affected. Indeed, the compaction is faster with the flow aid agent.

LEARN MORE ABOUT THE GRANUPACK

The results are summarizing in the next table. The parameter n1/2 characterizes the compaction speed.

This parameter is strongly affected by the flow aid agent while the classical Hausner ratio is less affected.

| p(0) | p(1250) | Hausner | p(∞) | n1/2 | |

|---|---|---|---|---|---|

| Powder | 0.441 | 0.538 | 1.22 | 0.573 | 56.1 |

| Powder + Flow Aid | 0.479 | 0.574 | 1.199 | 0.592 | 12.3 |