Pharmaceutical

Dynamic Tap Density Tester as a useful tool for analyzing pharmaceutical powders (Granupack analyses)

The tap density test / tap test tool is a usefull compressibility tool commonly used in quality control and R&D for developing new formulations. This test can be used for calculating the Hausner ratio (Hr) or the Carr index value...

Introduction

The tap density test / tap test tool is a usefull compressibility tool commonly used in quality control and R&D for developing new formulations. This test can be used for calculating the Hausner ratio (Hr) or the Carr index value and, therefore, for classifing the powders following their flow ability and their compressibility.

However, these ratios are calculated only by considering the initial (V0) and final volume (V500) without considering the tapping/packing kinetic. In other words, a small error in one of these volumes (V0 or V500) can lead to false indexes and low reproducibility of the test.

To avoid this problem, we developed a new generation of tap density meter: The GranuPack

This instrument allows following the tapping/packing kinetic in all the range of the measurement. With this instrument, we are able to categorize more easily the powders with identical or close Hr and to realize a better classification of the powders without any waste of time.

In this study different lactoses have been analyzed for determining their flow ability by using new generation of tap density meter. We show that powders with identical Hausner ratio can be categorized with a new index based on the all tap density curve. We can also observe the effect of particle size on the tapping/compressibility kinetic for pharmaceutical powders.

LEARN MORE ABOUT THE GRANUPACK

Materials And Methods

Four categories of commercial lactoses have been used in this study: Granulac, Tabletose, Inhalac and Flowlac. All of them were supplied by Meggle. For each powder, the bulk density has been considered about 1.53 g/cm3. The relative humidity and the temperature during the analyses are respectively about 35% RH and 23°C. Particle size distributions have been measured by the Mastersizer 2000, in dry conditions (Malvern).

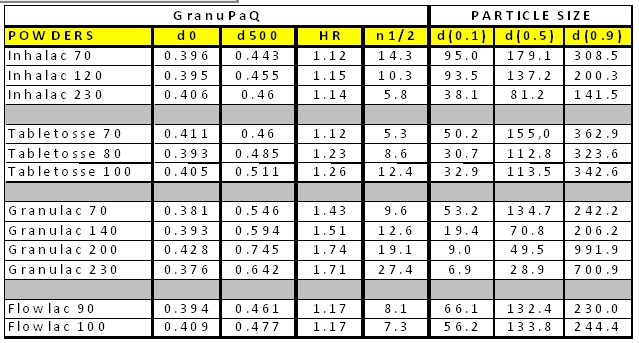

Table 1: Tap density parameters by using dynamic tap density measurement and particle size distribution descriptors

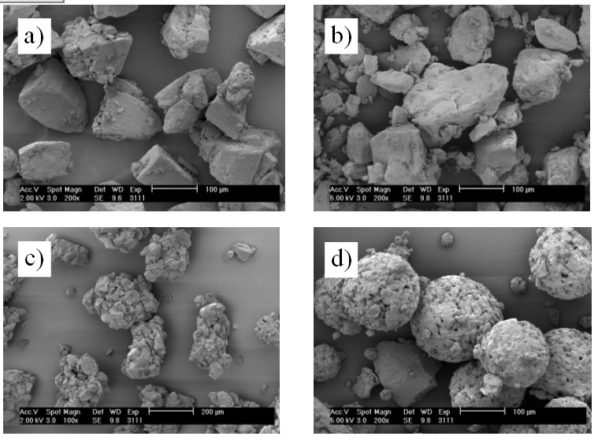

Figure 1 show the scanning electron micrographs of the lactoses excipients.

Whereas the grains of the Inhalac and Granlulac powder (Figure 2a and 2b) are sharp and compact, the grains of the Tablettose and the Flowlac powders are componed of hard coarse and spherical agregates, respectively.

Figure 1: Scanning electron micrographs of a) Inhalac70, b) Granulac70, c) Tabletosse70 and d) Flowlac100

The GranuPack Instrument

In order to check the evolution of the compressibility properties of the powders according to the time, GranuPack instrument has been developped. This instrument is able to record an integral compaction curve.

A powdered sample is poured in a tube which is submitted to a series of identical tap stress. Before measuring, an initialization procedure is made in order to avoid any bias. During the stress procedure, the volume fraction of the powder is tracked in order to estimate the relevant information: a dimensionless flowability index (n1/2) ranging typically from 3 (high flowability) to 30 (low flowability) is obtained. The Hr (Hausner) can be also calculated.

LEARN MORE ABOUT THE GRANUPACK

Results and Discussions

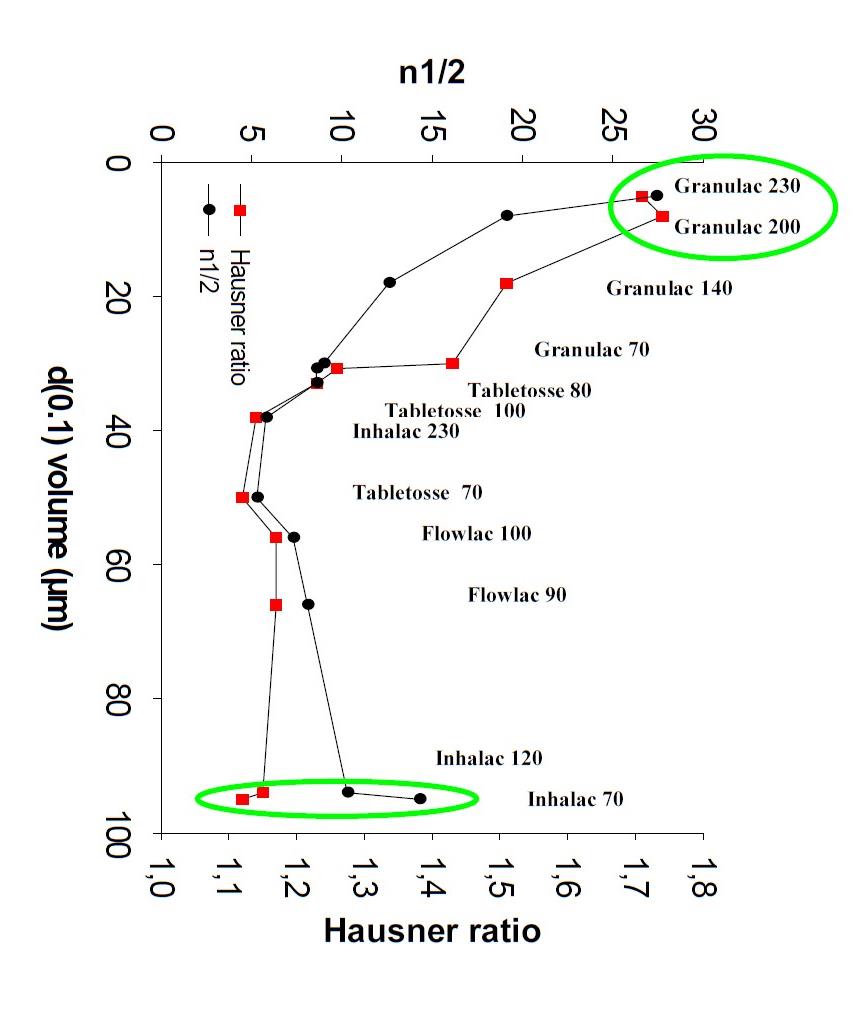

Figure 2 shows the correlation between the d(0.1) value and respectively the flow index (n1/2) and the Hausner ratio (Hr) for the different powders analyzed with the GranuPack instrument.

Figure 2: Correlation between d(0.1) value and respectively n1/2 and Hr for the different lactose excipients

We can observe that the n1/2 and the Hausner ratio value depend on the size of the fine particles measured in the powder (d0.1). So, by considering the figure 2, particle size seems to have a significant effect on the compaction of the powders. A strong correlation can be observed between the behavior of the flowability index n1/2 and the Hausner ratio in function of the smallest particles [d(0.1) values] which bring the big component of the friction. Indeed, the Hausner ratio and the n1/2 show a significant increase for powders characterized by d(0.1) lower than 40 µm. This correlation seems become less good in the extreme area (see green ellipses on figure 2):

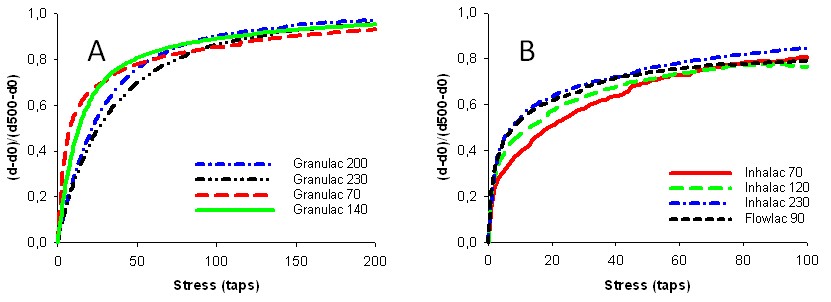

- Indeed, in the lowest range of d(0.1) values, powders Granulac200 and 230 can not be categorized by using the Hausner ratio alone. Don’t forget that for calculating the Hausner ratio, only the initial and final densities are used. There is not data about the tapping – packing kinetic. The Hausner ratio reduces thus the information obtained by the dynamical tap test density measurement at the initial and final stage. Conversely, the flowability index n1/2 is obtained by considering the compressibility dynamics, steps by steps, to obtain a complete flow curve (see figures 3A and 3B and below for corresponding text) which gives the packing kinetic. Therefore, although these two Granulac powders are characterized by a same Hausner ratio, they show very different flow indexes n1/2 values. It becomes now possible to better classify them. The kinetic parameter n1/2 allows categorizing the powders with high cohesion.

LEARN MORE ABOUT THE GRANUPACK

- Secondly, in the highest range of d(0.1) values, powders Inhalac 70, Inhalac 230 and Flowlac 90 seem to be difficult to categorize by using the Hausner ratio alone also. Here also, the flowability index n1/2 show very different values (see table 1). This behavorial differences can also be observed in the normalized flow curves (see figure 3 B). So, Inhalac 70 powder needs more time to reach its maximum packing fraction than Inhalac 120, Inhalac 230 and Flowlac 90 even if Inhalac 70 is characterized by a higher average grain size (see table 1). n1/2 is a kinetic parameter which takes into account of the packing dynamic of the powder and not only about the initial and the final state of packing. This parameter allows categorizing more easily the powders characterized by small physical differences.

Figure 3A shows the normalized flow curves obtained for the Granulac powders. On this figure, we can observe that powder Granulac 200 is characterized by a packing kinetic faster than the Granulac 230 excipient: it takes more time for powder Granulac 230 to reach its maximum packing fraction than the Granulac 200 powder. So, n1/2 gives relevant information on the compaction and the flowability of the powders (cf. table 1). Figure 3B shows the corresponding results recorded for the Inhalac and Flowlac lactose excipients.

Figure3: Normalized flow curves obtained for a) Granulac and b) Flowlac-Inhalac powders

Conclusions

We show in this study that there is a strong correlation between the Hausner ratio, the flow ability index (n1/2) and the particle size (d0.1). Moreover, we observe that powders with identical Hausner ratio can be categorized by using a new index based on the all tap density measurement / tap density curve.

We show that compaction kinetic measured by the dynamic tap density tester GranuPack can give important information on the flow powder behavior.