All resources

GranuPack: High resolution tapped density analyzer: Comparison vs Densi-Tap

The GranuPack instrument is an automated and improved tapped density measurement method based on recent fundamental research results. The behaviour of the powder submitted to successive taps is analysed with an automatized device...

Introduction

Theoretical Framework

Granular materials and fine powders are widely used in industrial applications. To control and to optimize processing methods, these materials have to be precisely characterized. The characterization methods are related either to the properties of the grains (granulometry, morphology, chemical composition, …) and to the behaviour of the bulk powder (flowability, density, blend stability, electrostatic properties, …).

However, concerning the physical behaviour of bulk powder, most of the techniques used in R&D or quality control laboratories are based on old measurement techniques. During the last decade, we have updated these techniques to meet the present requirements of R&D laboratories and production departments. In particular, the measurement processes have been automatized and rigorous initialization methods have been developed to obtain reproducible and interpretable results. Moreover, the use of image analysis techniques improves the measurements precision.

A range of measurement methods has been developed to cover all the needs of industries processing powders and granular materials. However, in this application note, we will be focused on the GranuPack instrument.

GranuPack

The bulk density, the tapped density and the Hausner ratio measurement (commonly named “tap tap test”) is very popular for powder characterization because of both the simplicity and the rapidity of the measurement. Moreover, the density and the ability of a powder to increase its density are important parameters for storage, transportation, caking, etc. The recommended procedure is defined in the pharmacopeia.

LEARN MORE ABOUT THE GRANUPACK

This simple test has three major drawbacks:

- First, the result of the measurement depends on the operator. Indeed, the filling method influences the initial powder volume.

- Secondly, the volume measurements by naked eyes induce strong errors on the results.

- Finally, with this simple method, we completely miss the compaction dynamics between the initial and the final measurements.

The GranuPack instrument is an automated and improved tapped density measurement method based on recent fundamental research results. The behaviour of the powder submitted to successive taps is analysed with an automatized device. The Hausner ratio Hr, the initial density ρ(0) and the final density after n taps ρ(n) are measured precisely. The tap number is commonly fixed at n=500. Moreover, a dynamical parameter n1/2 and an extrapolation of the maximum density ρ(∞) are extracted from compaction curves. Additional indexes can be used but they are not presented in this report.

The powder is placed in a metallic tube with a rigorous automated initialization process. Afterward, a light hollow cylinder is placed on the top of the powder bed to keep the powder/air interface flat during the compaction process. The tube containing the powder sample rose to a fixed height of ΔZ and performs free falls. The free fall height is generally fixed to ΔZ = 1mm or ΔZ=3mm. The height h of the powder bed is measured automatically after each tap. From the height h, the volume V of the pile is computed. As the powder mass m is known, the density ρ is evaluated and plotted after each tap. The density is the ratio between the mass m and the powder bed volume V.

With the GranuPack method, the results are reproducible with a small quantity of powder (typically 35 ml). The Hausner ratio Hr is related to the compaction ratio and is calculated by the equation Hr = ρ(500) / ρ(0) , where ρ(0) is the initial bulk density and ρ(500) the tapped density computed obtained after 500 taps.

LEARN MORE ABOUT THE GRANUPACK

Powders description

In order to make comparison between Densi-Tap and GranuPack instruments, three food powders were selected. They are called Powder A, B and C. Powder A and powder B are vegetal powders and powder C is a protein. Each sample was analysed under the same humidity/temperature conditions (± 1°C and 1%).

LEARN MORE ABOUT THE GRANUPACK

All measurements were carried out by the LRGP (Laboratoire Réactions et Génie des Procédés – University of Lorraine, Nancy, France) by Assia Saker under the guidance of Pr. Philippe Marchal.

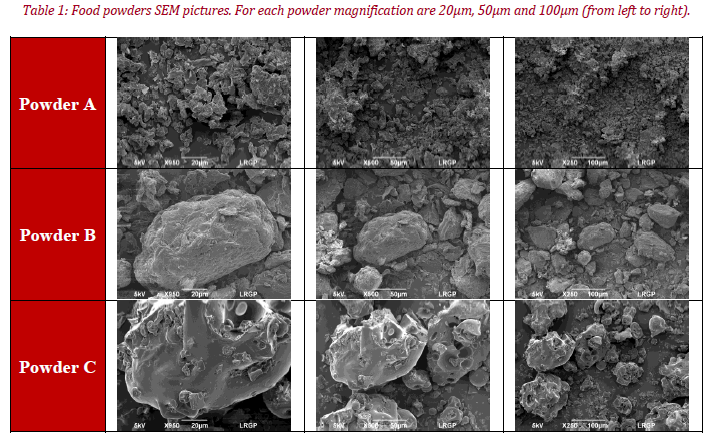

Table 1: Food Powders SEM pictures. For each powder magnification are 20µm, 50µm and 100µm (from left to right)

| Sample Name | Particle Size Distribution ±1µm | Morphology | True Density ± 0.01 (g/ml) | |||||

|---|---|---|---|---|---|---|---|---|

| d(4.3) | d(3.2) | d10 | d50 | d90 | Span | |||

| Powder A | 8 | 15 | 6 | 14 | 38 | 3 | Agglomerate | 1.46 |

| Powder B | 24 | 82 | 14 | 74 | 155 | 2 | Irregular | 1.47 |

| Powder C | 184 | 282 | 123 | 267 | 472 | 1 | Isometric rough | 1.23 |

Table 2: Particle size, morphology and densities of food powders

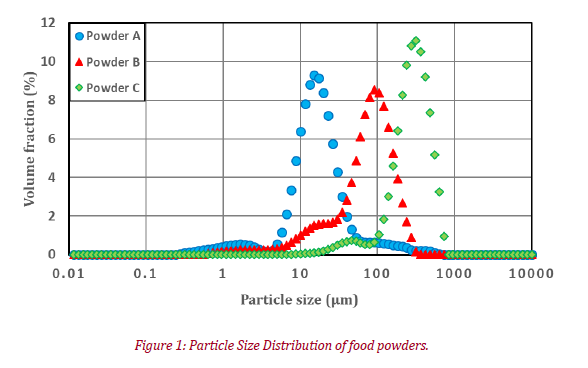

Figure 1: Particle size distribution of food powders

Densi-Tap analysis

Densi-Tap is designed to measure the bulk density of both powders and formed particles (maximum size about 5 mm). The sample is poured into a graduated cylinder (total volume of 250 mL) hinged on a tapping device. Before the taps, initial sample volume is read by eyes on a cylinder graduation. Finally, when tapping is completed (in this paper, 500 taps were made), the tapped volume is read by the same way. These steps allow to determine initial, final bulk density and to calculate the Hausner/Carr ratios. For each powder, measurements have been repeated 3 times (by the same person – since Densi-Tap is user dependent) to prove results reproducibility:

| Powder A | ||||||

|---|---|---|---|---|---|---|

| mp (g) | 65.87 | |||||

| T(°C) | Vi (ml) | Vf (ml) | ρi (g/ml) | ρf (g/ml) | Hr | Cr |

| 23.4 | 184 | 150 | 0.36 | 0.44 | 1.23 | 18.48 |

| 23.6 | 184 | 149 | 0.36 | 0.44 | 1.23 | 19.02 |

| 23.8 | 184 | 150 | 0.36 | 0.44 | 1.23 | 18.48 |

| Average | 1.23 | 18.66 |

| Powder B | ||||||

|---|---|---|---|---|---|---|

| mp (g) | 115.92 | |||||

| T(°C) | Vi (ml) | Vf (ml) | ρi (g/ml) | ρf (g/ml) | Hr | Cr |

| 21.6 | 170 | 139 | 0.68 | 0.83 | 1.22 | 18.24 |

| 21.8 | 174 | 141 | 0.67 | 0.82 | 1.23 | 18.97 |

| 22.2 | 170 | 140 | 0.68 | 0.83 | 1.21 | 17.65 |

| Average | 1.22 | 18.28 |

| Powder C | ||||||

|---|---|---|---|---|---|---|

| mp (g) | 75.85 | |||||

| T(°C) | Vi (ml) | Vf (ml) | ρi (g/ml) | ρf (g/ml) | Hr | Cr |

| 21.6 | 182 | 149 | 0.42 | 0.51 | 1.22 | 18.13 |

| 21.7 | 182 | 149 | 0.42 | 0.51 | 1.22 | 18.13 |

| 21.7 | 182 | 149 | 0.42 | 0.51 | 1.22 | 18.13 |

| Average | 1.22 | 18.13 |

Table 3: Densi-Tap experimental results for powders A, B & C

Table 3 shows that every powder is different in terms of initial and final bulk densities. However, for every test, Densi-Tap instrument cannot show difference between powders for the flowability values. Indeed, for powder A, B & C Hausner and Carr ratios are nearly the same. These assumptions may be explained by the small measurements accuracy (sample volume determination is made by eyes). Finally, since the Densi-Tap instrument only gives two information (initial and final densities), it is unable to show sample compaction kinetics.

GranuPack Analysis

The main purpose of this part is to prove the high accuracy of the GranuPack instrument and to highlight the importance of samples compaction kinetics. To prove these assumptions, tests have been repeated many times with the same powders (cf. Table 4, with 500 taps and a tap free-fall of 3mm) and full average compactions variation (ρ – ρ(0)) curves were plotted (the user interested in every bulk density measurements can refer to Appendix 2):

LEARN MORE ABOUT THE GRANUPACK

| Sample Name | ρ(0) | Mean ρ(0) | ρ(n) | Mean ρ(n) | n1/2 | Mean n1/2 | Hr | Mean Hr | Cr | Mean Cr | ρ(∞) | Mean ρ | τ | Mean τ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Powder A Test 1 | 0.369 | 0.367 | 0.487 | 0.483 | 13.7 | 13.8 | 1.318 | 1.316 | 24.1 | 24.0 | 0.516 | 0.513 | 9.5 | 10.5 |

| Powder A Test 2 | 0.363 | 0.479 | 13.7 | 1.319 | 24.2 | 0.509 | 11.0 | |||||||

| Powder A Test 3 | 0.369 | 0.484 | 14 | 1.311 | 23.7 | 0.514 | 11.1 | |||||||

| Powder B Test 1 | 0.652 | 0.651 | 0.792 | 0.790 | 9.3 | 9.1 | 1.216 | 1.215 | 17.7 | 17.7 | 0.826 | 0.824 | 7.9 | 8.1 |

| Powder B Test 2 | 0.649 | 0.788 | 8.9 | 1.214 | 17.6 | 0.822 | 8.2 | |||||||

| Powder C Test 1 | 0.42 | 0.418 | 0.482 | 0.481 | 14.6 | 14.7 | 1.147 | 1.151 | 12.8 | 13.1 | 0.500 | 0.500 | 18.9 | 21.1 |

| Powder C Test 2 | 0.425 | 0.482 | 16.3 | 1.136 | 11.9 | 0.501 | 24.8 | |||||||

| Powder C Test 3 | 0.41 | 0.479 | 13.1 | 1.169 | 14.5 | 0.500 | 19.7 |

Table 4: GranuPack experimental results for every food powder

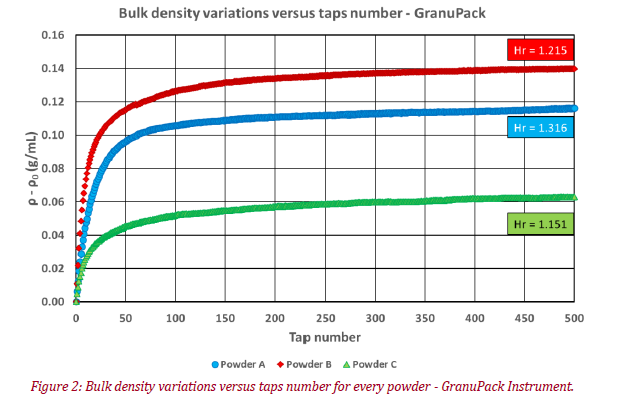

Figure 2: Bulk Density variations versus taps number for every powder - GranuPack instrument

Table 4 highlights the GranuPack reproducibility and by the looks of every values/constants, we can see that a high accuracy (approximately 0.4% – for the bulk densities values) and the non-user dependency are achieved

Figure 2 shows that the GranuPack instrument is able to classify the powders. Due to its high accuracy and non-user dependency, we can show high differences in terms of Hausner and Carr ratios. Indeed, Powder C has the best flow-ability (Hr = 1.151), it is quickly followed by Powder B (Hr = 1.215). Finally, Powder A has the worse flow-ability with a Hausner ratio close to 1.316.

With the n1/2 and τ constants (refer to Appendix 1), the GranuPack instrument can characterize powders compaction kinetics. Indeed, with these constants, we can see that powder B has a faster compaction than powder A, which is better than powder C.

LEARN MORE ABOUT THE GRANUPACK

Finally, with the comparison between ρ(n) and ρ(∞) we can conclude that the number of taps was not enough to reach the final (optimal) bulk density which is 0.513g/mL for Powder A, 0.824g/mL for Powder B and 0.500g/mL for Powder C. This information (which is not displayed by Densi-Tap instrument) allows user to define Standard Operating Procedures (SOP) and to determine with precision how many taps are needed to reach the optimal bulk density. The main purpose is to save time and energy for all future experiences.

Conclusions

- For some powders, the Densi-Tap instrument cannot highlight the difference, in terms of flow-ability (with Hausner and Carr ratios) due to its low accuracy and user dependency (powder manually poured inside the measurement cell and volume lecture made by eyes);

- Densi-Tap only provides two values (initial and final bulk density). Thus, it is not able to analyse the compaction kinetic;

- The GranuPack instrument, due to its high measurements precision (3 digits for Hausner/Carr ratios and bulk density – the error rate is close to 0.4% in bulk density measurements) and its non-user dependency can classify a lot of different samples with great accuracy;

- The GranuPack provides powders full compaction curves, which allows the user to highlight the kinetics of the compaction of every samples. It also allows to have other information about the compaction ease phenomenon;

- p (∞) values can help to define Standard Operating Procedures (SOP) and to easily know if the number of applied taps has been sufficient.

LEARN MORE ABOUT THE GRANUPACK

References

Cascade of granular flows for characterizing segregation, G. Lumay, F. Boschin, R. Cloots, N. Vandewalle, Powder Technology 234, 32-36 (2013).

Combined effect of moisture and electrostatic charges on powder flow, A. Rescaglio, J. Schockmel, N. Vandewalle and G. Lumay, EPJ Web of Conferences 140, 13009 (2017).

Compaction dynamics of a magnetized powder, G. Lumay, S. Dorbolo and N. Vandewalle, Physical Review E 80, 041302 (2009).

Compaction of anisotropic granular materials: Experiments and simulations, G. Lumay and N. Vandewalle, Physical Review E 70, 051314 (2004).

Compaction Dynamics ofWet Granular Assemblies, J. E. Fiscina, G. Lumay, F. Ludewig and N. Vandewalle, Physical Review Letters 105, 048001 (2010).

Effect of an electric field on an intermittent granular flow, E. Mersch, G. Lumay, F. Boschini, and N. Vandewalle, Physical Review E 81, 041309 (2010).

Effect of relative air humidity on the flowability of lactose powders, G. Lumay, K. Traina, F. Boschini, V. Delaval, A. Rescaglio, R. Cloots and N. Vandewalle, Journal of Drug Delivery Science and Technology 35, 207-212 (2016).

Experimental Study of Granular Compaction Dynamics at Different Scales: Grain Mobility, Hexagonal Domains, and Packing Fraction, G. Lumay and N. Vandewalle, Physical Review Letters 95, 028002 (2005).

Flow abilities of powders and granular materials evidenced from dynamical tap density measurement, K. Traina, R. Cloots, S. Bontempi, G. Lumay, N. Vandewalle and F. Boschini, Powder Technology, 235, 842-852 (2013).

Flow of magnetized grains in a rotating drum, G. Lumay and N. Vandewalle, Physical Review E 82, 040301(R) (2010).

How tribo-electric charges modify powder flowability, A. Rescaglio, J. Schockmel, F. Francqui, N. Vandewalle, and G. Lumay, Annual Transactions of The Nordic Rheology Society 25, 17-21 (2016).

Influence of cohesives forces on the macroscopic properties of granular assemblies, G. Lumay, J. Fiscina, F. Ludewig and N. Vandewalle, AIP Conference Proceedings 1542, 995 (2013).

Linking compaction dynamics to the flow properties of powders, G. Lumay, N. Vandewalle, C. Bodson, L. Delattre and O. Gerasimov, Applied Physics Letters 89, 093505 (2006).

Linking flowability and granulometry of lactose powders, F. Boschini, V. Delaval, K. Traina, N. Vandewalle, and G. Lumay, International Journal of Pharmaceutics 494, 312–320 (2015).

Measuring the flowing properties of powders and grains, G. Lumay, F. Boschini, K. Traina, S. Bontempi, J.-C. Remy, R. Cloots, and N. Vandewall, Powder Technology 224, 19-27 (2012).

Motion of carbon nanotubes in a rotating drum: The dynamic angle of repose and a bed behavior diagram, S. L. Pirard, G. Lumay, N. Vandewalle, J-P. Pirard, Chemical Engineering Journal 146, 143-147 (2009).

Mullite coatings on ceramic substrates: Stabilisation of Al2O3–SiO2 suspensions for spray drying of composite granules suitable for reactive plasma spraying, A. Schrijnemakers, S. André, G. Lumay, N. Vandewalle, F. Boschini, R. Cloots and B. Vertruyen, Journal of the European Ceramic Society 29, 2169–2175 (2009).

Rheological behavior of β-Ti and NiTi powders produced by atomization

for SLM production of open porous orthopedic implants, G. Yablokova, M. Speirs, J. Van Humbeeck, J.-P. Kruth, J. Schrooten, R. Cloots, F. Boschini, G. Lumay, J. Luyten, Powder Technology 283, 199–209 (2015).

The influence of grain shape, friction and cohesion on granular compaction dynamics, N. Vandewalle, G. Lumay, O. Gerasimov and F. Ludewig, The European Physical Journal E (2007).