Granutools is also a supplier of powder characterization instruments for the food industry. Working with a wide ranger of top actors producing anything from flour to spices.

Granutools unique powder characterization range of equipment allows high versatility regarding the range of compatible powders. No matter what your product is, contact Granutools to get more data on your application.

Granutools is a must-have for many R&D labs working with a wide range of powder. Do you want to create a new product? Or improve an existing one? Soon you’ll find out that slight changes in formulation or humidity may have a huge impact on powder processability. Contact us and talk to our experts!

Granular Materials are widely present in the food industry and their optimal processing represents an important challenge!

Granutools has been working with the leaders of the industry to help to predict potential flowability & caking issues at the formulation stage, therefore optimizing the process, and saving costs.

Humidity & temperature have a tremendous influence on the processing of food powders. As you can see in user cases below, moisture absorption can create agglomerates that prevent correct processability of powders highlighting again the importance of powder characterization early in the process.

On the other end, the packing dynamics will also have a big impact on the quality of the final product. Transport can cause packing and compaction leaving the final customer with a box half-filled or agglomerated into one block.

Finally, electrostatics can play a role in the processability of your powder, especially in the continuous manufacturing process. The charge builds up of some powder may cause caking, agglomerates, and sticking. Getting to know where your powder is being charged will help you discharge it either by using the right material for your installation or just by using some additives.

Granutools can help you to optimize processes like packaging, mixing, transportation, and many more.

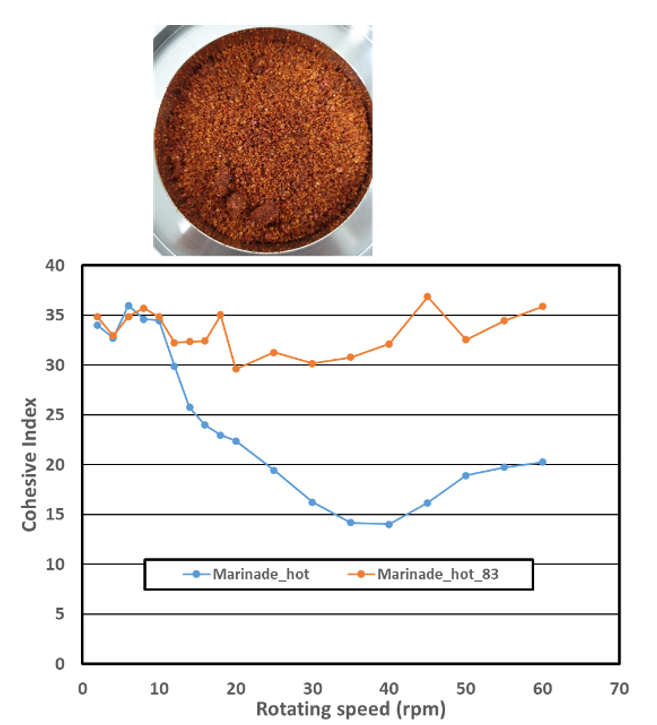

On the right figure, you can see how moisture absorption can create agglomerates and caking that will prevent the good processability of this powder (in this case a spice mix). The Granudrum can measure this powder tendency to create agglomerates and cake and how it will affect the flowability. You can see below the results of the same spice mix with two conditioning: one at room humidity (40%) and the other one conditioned 2 hours at 83% humidity. We can see that higher moisture content increases the cohesive behavior of the powder due to the formation of capillary bridges. We also observe that the rheological behavior is greatly influenced by humidity especially we can see that for the sample conditioned at higher humidity the shear thinning behavior is no longer there. Moreover, dynamic testing like the rotating drum flowmeter can help you to understand the impact of the processing speed on your formulated product.

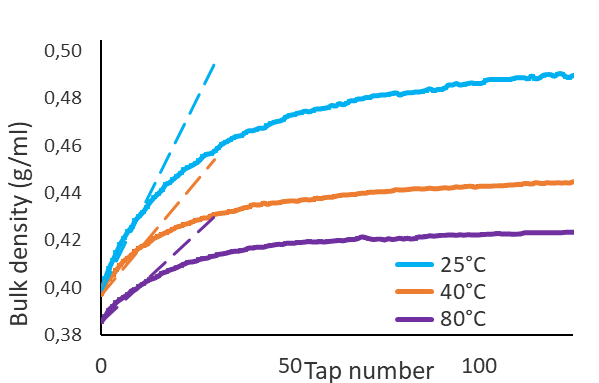

The graph below is showing the packing curves of the cocoa powder at different temperatures. Those curves were obtained with the GranuPack High temperature. As shown, the ability of the cocoa to pack is highly dependent on the temperature. Hausner ratio for such powder can be measured very easily but without any control of the environmental conditions, such measurements are not relevant. Understanding the relevance of the measurement for your product is the key to good product characterization. The control of the humidity and the temperature are mandatory for such sensitive powders especially for companies working on several continents.

On the manufacturing site, processability is often a big question. And when the production is running smoothly, it’s sometimes complicated to make some change. Setting thresholds on powder processability will allow an industrial to understand the range of flowability that his installation can handle.

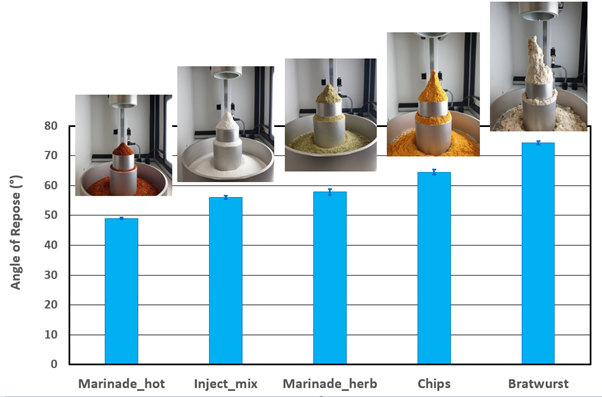

The angle of repose (here done with the GranuHeap) can be a good characteristic for such application. In just a few seconds you can measure this data and sort your product from best to worst in terms of flowability. Quickly you will be able to set threshold and predict the processability of your product in every step of the process.