Working with metal powder producers for the additive manufacturing industry, Granutools was able to understand deeply the behavior of such powder even in other applications. From metal injection molding to coating, contact us, and have a chat with our expert about your application, and learn more about powder behavior.

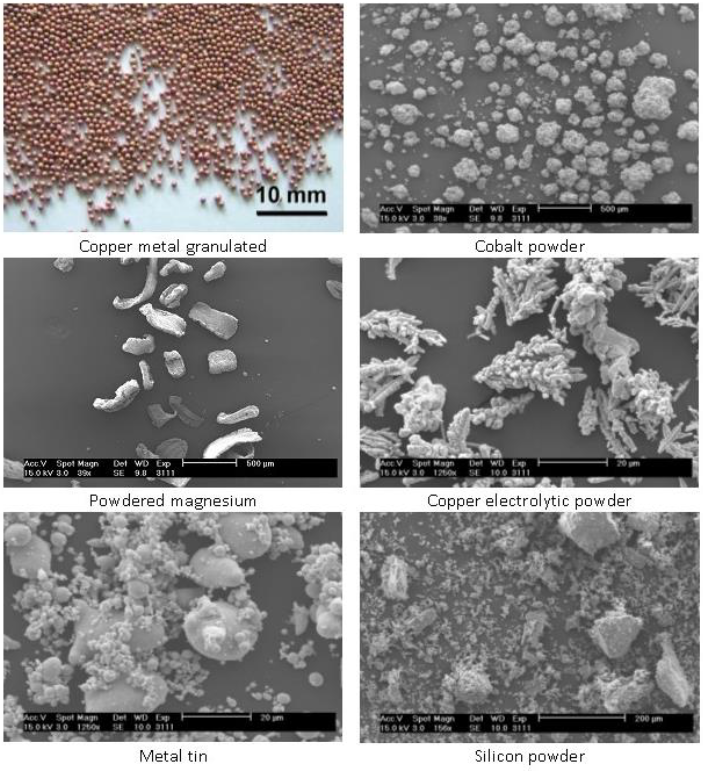

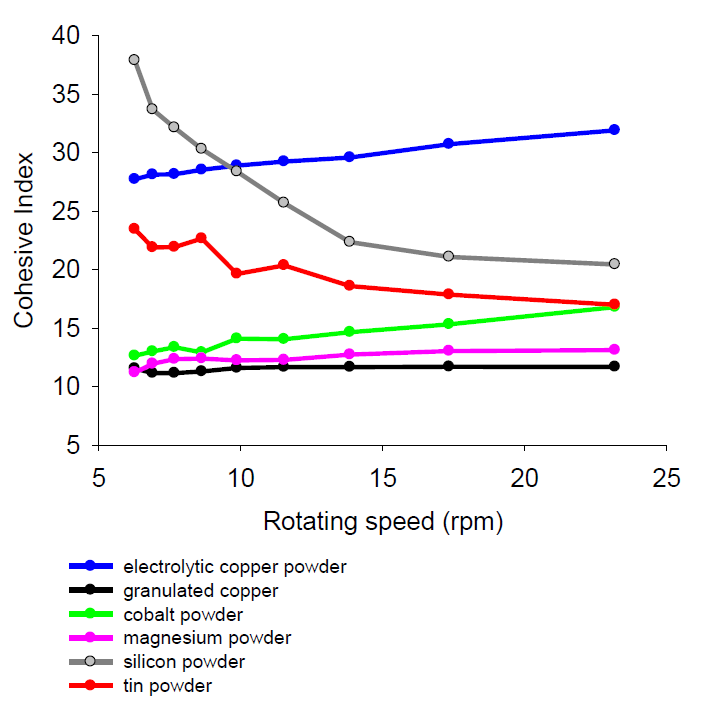

In this user case, several metal powders were analyzed by using the GranuDrum. The principal characteristics of these powders diverge in their grain size, shapes, and the nature of their materials.

Three categories of powders were found:

These results show that the GranuDrum instrument allows categorizing metal powders very easily at low and high speed. The instrument allows also to determine if the powder presents a hysteresis loop. This method allows for easy sorting of powder where PSD and shape analysis could not provide such a direct result.

Granular materials and fine powders are widely used in industrial applications. To control and to optimize processing methods, these materials have to be precisely characterized. The characterization methods are related either to the properties of the grains (granulometry, morphology, chemical composition, …) and to the behavior of the bulk powder (flowability, density, blend stability, electrostatic properties, …). However, concerning the physical behavior of a bulk powder, most of the techniques used in R&D or quality control laboratories are based on old measurement techniques. During the last decade, we have updated these techniques to meet the present requirements of R&D laboratories and production departments. In particular, the measurement processes have been automatized and rigorous initialization methods have been developed to obtain reproducible and interpretable results. Moreover, the use of image analysis techniques improves measurement precision.

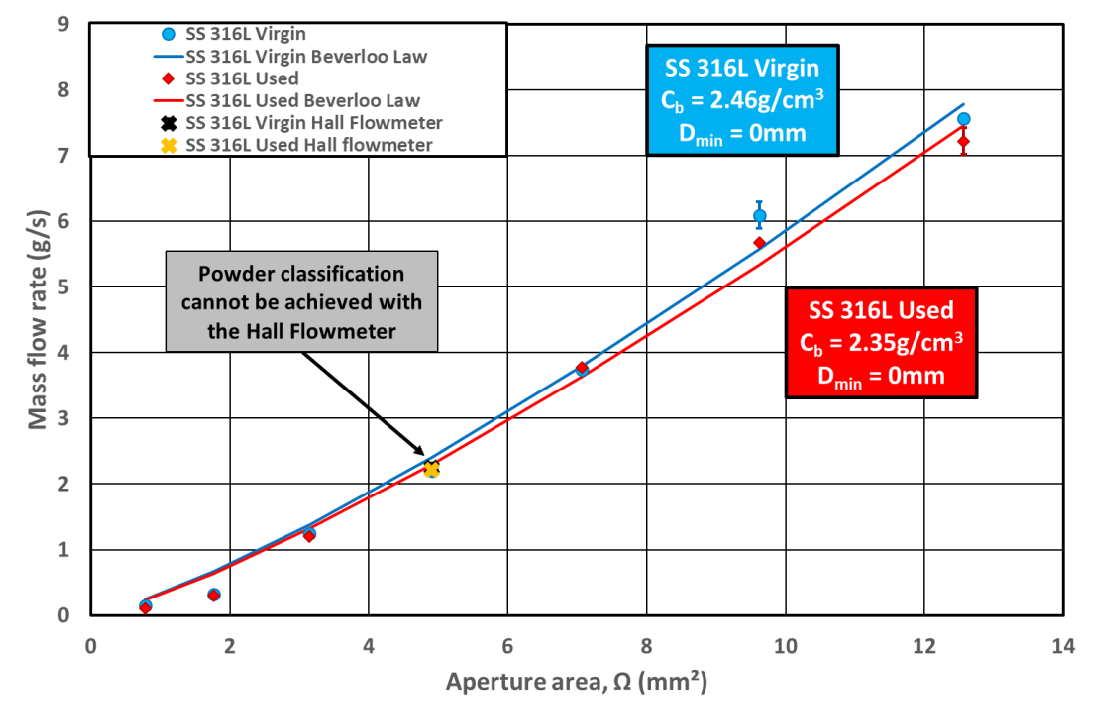

GranuFlow is an improved laboratory silo compared to the ancient Hall Flow Meter (ASTM B213, ISO4490) and compared to the “Flow-Through An Orifice” method described in the Pharmacopeia (USP1174).

GranuFlow is a straightforward powder flowability measurement device composed of a silo with different apertures associated with a dedicated electronic balance to measure the flowrate. This flowrate is computed automatically from the slope of the mass temporal evolution measured with the balance. The flowrate is measured for a set of aperture sizes to obtain a flow curve. Finally, the whole flow curve is fitted with the well-known Beverloo theoretical model to obtain a flowability index (Cb, related to the powder flowability) and the minimum aperture size to obtain a flow (Dmin)

A Stainless-Steel 316L powders provided by Höganäs was used for this application note. A comparison between the original powder and a used version (after an SLM process) is also proposed.